Thanks Kim. I’m going to remove the trans so I can get to the pump and drum. Roy is assuming the clutch teeth are a goner.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

318 LA rebuild after losing a valve seat

- Thread starter Righty Tighty

- Start date

-

I would think so also. Good luck. Kim

At least you found this now instead of after you fired the engine.

And now the update you've all been waiting for!

I followed the advice given by several of you and simply removed the crossmember to drop the tail down. It was much easier than I thought it would be. I made a cradle out of 2x4s and used a floor jack to slowly lower it while sliding it back. I think that was the sketchy part. When I put it back in, I'm either going to do a better job supporting it, or "rent" a transmission jack from HF. I should've followed pt70's advice and used more wood and 2x10s instead. As usual, the damn headers were in the way. Oh, I also disconnected the exhaust hangers to get the x-pipe out of the way.

Now time to remove the pump and get to the front drum. Let me tell you guys, I am extremely lucky I didn't damage the threads in the pump. The parts store only had a regular slide hammer, so I had to improvise with a bolt I had. I forgot that the threads for pulling the pump are LARGER than the fastener threads. I banged on that damn thing pretty good with a bolt in the fastener hole, not the larger hole. I caught myself in time, switched to a larger bolt at 3/8 x 16, and it came right out. Surprisingly, the clutch plate teeth look just fine, and from what I could see of the friction material, they don't look burned up. Here's a view of the inside of the drum.

I was also expecting to have to replace the band, but it looks good. I suspect this transmission was recently rebuilt. What are your thoughts?

Now look at the first photo of the band. See that washer?? DOH!!! I now understand why folks recommend installing the pump with the transmission vertical. So, what I think happened was a series of errors made by me. I didn't tighten the band down before removing the pump, causing things to drop down after it was removed (including that washer). With the pump out, I turned the input shaft just because I'm a curious monkey and wanted to see it spin. I think that misaligned the tangs of the drum. Then when I re-installed the pump, I just jammed it in there and ran down the bolts. The misaligned tangs never realigned, and the washer got smashed just where it sat.

I decided not to replace the clutch plates and steels, because to me (pops agreed) they look fine. I didn't want to go digging around and increase my chances of making another mistake if I didn't have to. I'm waiting for the transmission shop to open so I can go get another washer and receive my deserved flogging from Keith, the owner. Then I'll have pops come over and help with the assembly....this time in the VERTICAL position!

I followed the advice given by several of you and simply removed the crossmember to drop the tail down. It was much easier than I thought it would be. I made a cradle out of 2x4s and used a floor jack to slowly lower it while sliding it back. I think that was the sketchy part. When I put it back in, I'm either going to do a better job supporting it, or "rent" a transmission jack from HF. I should've followed pt70's advice and used more wood and 2x10s instead. As usual, the damn headers were in the way. Oh, I also disconnected the exhaust hangers to get the x-pipe out of the way.

Now time to remove the pump and get to the front drum. Let me tell you guys, I am extremely lucky I didn't damage the threads in the pump. The parts store only had a regular slide hammer, so I had to improvise with a bolt I had. I forgot that the threads for pulling the pump are LARGER than the fastener threads. I banged on that damn thing pretty good with a bolt in the fastener hole, not the larger hole. I caught myself in time, switched to a larger bolt at 3/8 x 16, and it came right out. Surprisingly, the clutch plate teeth look just fine, and from what I could see of the friction material, they don't look burned up. Here's a view of the inside of the drum.

I was also expecting to have to replace the band, but it looks good. I suspect this transmission was recently rebuilt. What are your thoughts?

Now look at the first photo of the band. See that washer?? DOH!!! I now understand why folks recommend installing the pump with the transmission vertical. So, what I think happened was a series of errors made by me. I didn't tighten the band down before removing the pump, causing things to drop down after it was removed (including that washer). With the pump out, I turned the input shaft just because I'm a curious monkey and wanted to see it spin. I think that misaligned the tangs of the drum. Then when I re-installed the pump, I just jammed it in there and ran down the bolts. The misaligned tangs never realigned, and the washer got smashed just where it sat.

I decided not to replace the clutch plates and steels, because to me (pops agreed) they look fine. I didn't want to go digging around and increase my chances of making another mistake if I didn't have to. I'm waiting for the transmission shop to open so I can go get another washer and receive my deserved flogging from Keith, the owner. Then I'll have pops come over and help with the assembly....this time in the VERTICAL position!

Post pics of the back of the pump Kim

Here’s the back of the pump.

Make sure the sealing rings are good and that there is no scoring on it or in the front drum. Kim

Thanks Kim, everything appears blemish free and the rings are new. BUT...I was giving the drum one more inspection before launch, and something caught my eye.

So I separated it and found this.

Back to the shop I go...to replace whatever that was that broke. Dammit.

So I separated it and found this.

Back to the shop I go...to replace whatever that was that broke. Dammit.

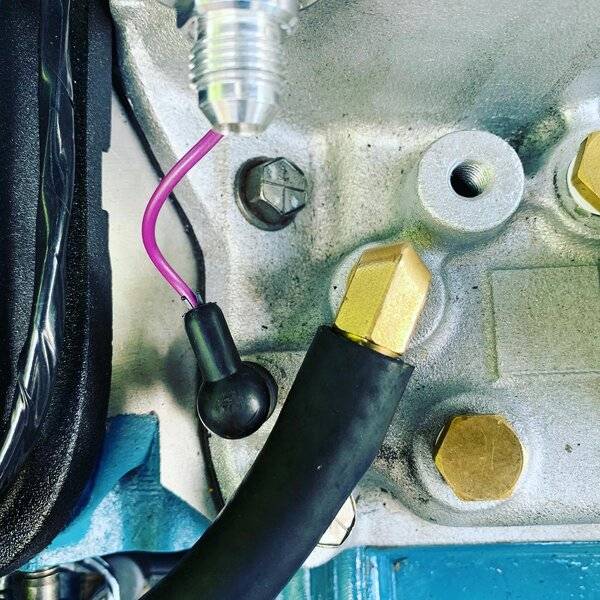

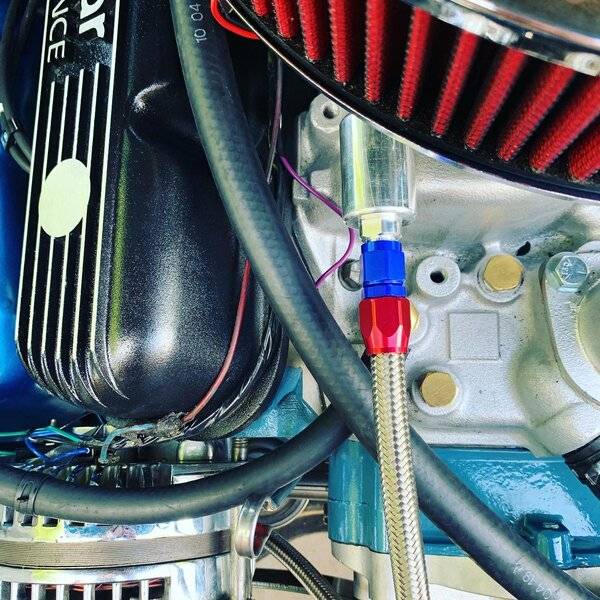

Well, thought I’d keep you all abreast of the current condition of the car. I’ve made lots of progress, and basically all that’s left now if connecting hoses and electrical. Today I worked on re-routing the heater hoses for a cleaner look than how it was previously, plus I had to negotiate the fuel line to the carb. I got pretty lucky with the adapter I chose, it JUST fit.

Nice. Kim

Getting close to the end. Gonna prime it one more time before installing the fan and radiator, then charge the battery and add fluids.

Is it weird that I’m getting nervous the closer I get to being ready to start it?

Is it weird that I’m getting nervous the closer I get to being ready to start it?

Getting close to the end. Gonna prime it one more time before installing the fan and radiator, then charge the battery and add fluids.View attachment 1715571114 Is it weird that I’m getting nervous the closer I get to being ready to start it?

For some reason it is hard to get all of the air out of the 318 block, heads, intake manifold and heater core and get it completely full of coolant before first start up.

With the radiator full and and as much coolant as you can get in it. I would loosen up the temp gauge sender unit in the front of the intake manifold and use that port as an air bleed for the top half of the engine before the thermostat has had a chance to open. Get some rags handy and loosen up that sender till the fluid starts coming out, then tighten it up again.

People have raised the front of the car way up, squeezed upper and lower radiator hoses, rev the engine, all not much help.

Think like at least 3 gallons of coolant to start with. May want to fill with coolant, let sit over night, top off again in the morning.

Keep in mind you want it full of coolant so you can keep it running to break in the cam properly at first start.

A short run of the engine at 2,000 rpm is supposed to pump the heater core full with the heat control valve at Full On.

Keep an eye on your coolant and keep it above the cores in the radiator, don't open radiator cap when engine is up to temp or it could burn you badly. One of those infra red heat tester guns is handy to have close by to check for hot spots.

Like I say for some reason the 318s are hard to burp all the air out of them, other engines just warm them up so the thermostat opens and top them off.

@318willrun knows about this too.

Crazy, but want you to be careful with your brand new engine . . don't want to overheat the heads right out of the gate.

Thanks George, very helpful info. Funny, I was actually going to ask if there was a way to prime the fuel system? I understand that I will prime the carb, but what about the fuel pump and all the lines? As everything sits currently, it is dry.

Thanks George, very helpful info. Funny, I was actually going to ask if there was a way to prime the fuel system? I understand that I will prime the carb, but what about the fuel pump and all the lines? As everything sits currently, it is dry.

If you prime/fill the fuel bowls on the carb then re-hook up your gas line from your fuel pump to the carb, it should run long enough on the fuel in the carb bowls till the fuel pump starts pumping gas and takes over from there.

Just did a complete dry fuel system startup with just fuel in the gas tank. Don't think I cranked it 10 seconds and it was up and running no problem. Fuel pump grabbed the gas, sent it to the carb and all was good.

But good to fill the bowls on the carb first if you can then it is ready to run immediately.

Well, I thought today was the day.

Pops and another friend came over to help out and act as extra hands and eyes. Good thing they did, because they spotted things that needed correction that I wouldn't have seen on my own. I wanted to flush the radiator prior to filling it with coolant, so my buddy plugged the lower hole while it filled so we could build some pressure to let the water flush any gunk out. The radiator filled and started to piss out water in a steady stream about halfway up on the fins. So that's that. I either need a new radiator or I need to repair this one.

Moving on, they noted that I had no fan shroud. Yes, that's because the fan I bought on eBay was a little larger than the OEM fan, and the shroud didn't fit. Well, this is when I learned that the shroud wasn't just for safety. So now I'm in the market for an OEM fan, which seems to be pretty damn hard to find. If anyone has a part number for a fan for a 318, I'd love to have it.

Slowly but surely, I'll get this car back on the road!

Pops and another friend came over to help out and act as extra hands and eyes. Good thing they did, because they spotted things that needed correction that I wouldn't have seen on my own. I wanted to flush the radiator prior to filling it with coolant, so my buddy plugged the lower hole while it filled so we could build some pressure to let the water flush any gunk out. The radiator filled and started to piss out water in a steady stream about halfway up on the fins. So that's that. I either need a new radiator or I need to repair this one.

Moving on, they noted that I had no fan shroud. Yes, that's because the fan I bought on eBay was a little larger than the OEM fan, and the shroud didn't fit. Well, this is when I learned that the shroud wasn't just for safety. So now I'm in the market for an OEM fan, which seems to be pretty damn hard to find. If anyone has a part number for a fan for a 318, I'd love to have it.

Slowly but surely, I'll get this car back on the road!

That sucks, better to find it now then after the motor is running. Kim

Well, I thought today was the day.

Pops and another friend came over to help out and act as extra hands and eyes. Good thing they did, because they spotted things that needed correction that I wouldn't have seen on my own. I wanted to flush the radiator prior to filling it with coolant, so my buddy plugged the lower hole while it filled so we could build some pressure to let the water flush any gunk out. The radiator filled and started to piss out water in a steady stream about halfway up on the fins. So that's that. I either need a new radiator or I need to repair this one.

Moving on, they noted that I had no fan shroud. Yes, that's because the fan I bought on eBay was a little larger than the OEM fan, and the shroud didn't fit. Well, this is when I learned that the shroud wasn't just for safety. So now I'm in the market for an OEM fan, which seems to be pretty damn hard to find. If anyone has a part number for a fan for a 318, I'd love to have it.

Slowly but surely, I'll get this car back on the road!

Checked on Rockauto for 71 Dart Radiators for 318 Auto, No Joy.

Looked up 1974 Dart 318, they show a 26" wide Brass Tanks, Copper Core radiator at Rockauto. Spectra CU499

replacement for small block 74 A body. 26" core.

Your Radiator is probably the 22" wide core. Here is an aluminum replacement to it on Ebay. Can search them on ebay

CU526 Radiator

22" x 18" core

The matching factory mopar shroud number is the "325" for the 22" A bodies.

2998325 mopar small block shroud, 22".

325 shroud will take an 18" diameter fan blade.

CU526 Mopar A Body 22" Radiators

Thanks George! I was doing some searching myself. You're right, I do have a 22" core. My shroud is good, and I was going to stop in at the local radiator shop to see how much he'd charge to repair my leaky radiator. It would be great to get a nice new aluminum job or even a new OEM unit, but my wallet is feeling a little light these days.

I did find some new 18" fans, but I'd rather not spend $150-200 for one, so I found a used one on eBay.

I did find some new 18" fans, but I'd rather not spend $150-200 for one, so I found a used one on eBay.

Northern Grit

Well-Known Member

A leak 1/2 way up is usually an easy spot to fix, especially if it got nicked and not caused by corrosion. I have had good luck by carefully peeling back just a few fins and pinching the hole flat, then clean and flux the area, then using one of those mini torches and some solder (gotta be dry inside) has saved my wallet more than once.I was going to stop in at the local radiator shop to see how much he'd charge to repair my leaky radiator. It would be great to get a nice new aluminum job or even a new OEM unit, but my wallet is feeling a little light these days.

.

A leak 1/2 way up is usually an easy spot to fix, especially if it got nicked and not caused by corrosion. I have had good luck by carefully peeling back just a few fins and pinching the hole flat, then clean and flux the area, then using one of those mini torches and some solder (gotta be dry inside) has saved my wallet more than once.

I was going to attempt it myself, but I figured I’d just keep piece of mind and have the shop do it. The way you describe the repair makes it sound really easy, although it’s a little too late since it’s already there being repaired.

Wyrmrider

Well-Known Member

just righty

SHE LIVES!!

It took about 1 year to the day and a lot of learning, but the Scamp is running again. Boy does it sound wonderful. When we first got it started, I found some oil leaks and a coolant leak that needed to be addressed, so we shut her off and let it cool so I could get to them without burning the **** out of myself on the headers.

Leaks repaired, I adjusted the idle setting and got the timing correct (I think). It idles wonderfully around 900 RPM and is maintaining a steady temperature.

Took it around the block to feel it shift, but the alignment is pretty far out. I think when I adjusted the torsion bars to raise the front, I tweaked the camber. No worries, I have an appointment for an alignment next week. It’s on the trailer currently, ready to be dropped off at the shop.

Thanks everyone for all the help and support! This has been an incredibly rewarding journey.

It took about 1 year to the day and a lot of learning, but the Scamp is running again. Boy does it sound wonderful. When we first got it started, I found some oil leaks and a coolant leak that needed to be addressed, so we shut her off and let it cool so I could get to them without burning the **** out of myself on the headers.

Leaks repaired, I adjusted the idle setting and got the timing correct (I think). It idles wonderfully around 900 RPM and is maintaining a steady temperature.

Took it around the block to feel it shift, but the alignment is pretty far out. I think when I adjusted the torsion bars to raise the front, I tweaked the camber. No worries, I have an appointment for an alignment next week. It’s on the trailer currently, ready to be dropped off at the shop.

Thanks everyone for all the help and support! This has been an incredibly rewarding journey.

Yeah. U did it. Kim

SHE LIVES!!

It took about 1 year to the day and a lot of learning, but the Scamp is running again. Boy does it sound wonderful. When we first got it started, I found some oil leaks and a coolant leak that needed to be addressed, so we shut her off and let it cool so I could get to them without burning the **** out of myself on the headers.

Leaks repaired, I adjusted the idle setting and got the timing correct (I think). It idles wonderfully around 900 RPM and is maintaining a steady temperature.

Took it around the block to feel it shift, but the alignment is pretty far out. I think when I adjusted the torsion bars to raise the front, I tweaked the camber. No worries, I have an appointment for an alignment next week. It’s on the trailer currently, ready to be dropped off at the shop.

Thanks everyone for all the help and support! This has been an incredibly rewarding journey.

Thumbs Up my friend !

-

Similar threads

- Replies

- 37

- Views

- 1K

- Replies

- 16

- Views

- 354

- Replies

- 26

- Views

- 1K