Yep, that's why I used some comps.. also because I found them on sale for $200 at summit in their scratch and dent section lolHere a pic of a Comp Pro Magnum:

What you can’t see in this pic is there is also a spring relief cast into the body.

View attachment 1715308996

Notice the difference in the relationship between the adjuster cup and the roller tip between the two rockers.

The PRW rocker has the roller higher up vs the center of the shaft, so the rocker has to be rotated down farther for the tip to contact the valve, which results in the contact with the retainer.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

35% off SpeedMaster

- Thread starter skrews

- Start date

-

Initial report was the car picked up .28.....but he was running into a 15 mph head wind.....did not go to the track this weekend....will see him and the car this weekend to see the time slips.

Well..."They" took a 11.60 car and got it to run 12.50s......changed crap after each run....jettted up ..jetted down...took the power valve out...took the spacer out...only to put it back after it slowed...had the valve cover off and on...told me it lost a cam lobe....couple rockers had backed off....anyway...I get the car back this weekend and will get it straighten out and back to the track ....going to be away as out bracket program is now done until Sept...

nm9stheham

Well-Known Member

Ow... darn 'them'.

gzig5

Well-Known Member

Here a pic of a Comp Pro Magnum:

What you can’t see in this pic is there is also a spring relief cast into the body.

View attachment 1715308996

Notice the difference in the relationship between the adjuster cup and the roller tip between the two rockers.

The PRW rocker has the roller higher up vs the center of the shaft, so the rocker has to be rotated down farther for the tip to contact the valve, which results in the contact with the retainer.

Really surprised and a little concerned that the PRW rockers didn't fit. I've heard nothing but good things and got the same ones set aside for when I put in an XE275HL cam, and the recommended spring is 1.44" diameter. Guess I'll look into beehive springs.

nm9stheham

Well-Known Member

Tnx. And it looks like the PRW's adjuster sets lower relative to the centerline of the shaft, if you imagine where a line perpendicular to the adjuster axis intersects centerline of the shaft. (My 1st impression would be that there is more motion lost on both sides of the PRW, but that needs more thinking out.....)Here a pic of a Comp Pro Magnum:

What you can’t see in this pic is there is also a spring relief cast into the body.

View attachment 1715308996

Notice the difference in the relationship between the adjuster cup and the roller tip between the two rockers.

The PRW rocker has the roller higher up vs the center of the shaft, so the rocker has to be rotated down farther for the tip to contact the valve, which results in the contact with the retainer.

I have a set that I bought back in 2012. I worked them over and had them flowed last week.

.100-90/83

.200-150/134

.300-207/170

.400-252/189

.500-285/205

.600-297/208

.700-306

I don't know what bench they were flowed on or any of the nitty gritty details. My machinist wants to flow them again...I guess to verify what he is seeing is correct. I should know more Monday. I will be looking for another bench to put them on also.

.100-90/83

.200-150/134

.300-207/170

.400-252/189

.500-285/205

.600-297/208

.700-306

I don't know what bench they were flowed on or any of the nitty gritty details. My machinist wants to flow them again...I guess to verify what he is seeing is correct. I should know more Monday. I will be looking for another bench to put them on also.

LI have a set that I bought back in 2012. I worked them over and had them flowed last week.

.100-90/83

.200-150/134

.300-207/170

.400-252/189

.500-285/205

.600-297/208

.700-306

I don't know what bench they were flowed on or any of the nitty gritty details. My machinist wants to flow them again...I guess to verify what he is seeing is correct. I should know more Monday. I will be looking for another bench to put them on also.

I would look for another bench too. Either that or someone forgot to screw a spark plug in the spark plug hole. Lol. That’s the reason way I always flow and give before and after numbers.

I'd be happier than a pig in **** if those are correct but I have my doubts. He had a lot of questions over the phone lol. Hopefully find out in the next couple weeks what we have goin. He should be able to calibrate the bench and go from there right? Its date night so I won't be back on till morning if I play my cards right lol

I'd be happier than a pig in **** if those are correct but I have my doubts. He had a lot of questions over the phone lol. Hopefully find out in the next couple weeks what we have goin. He should

be able to calibrate the bench and go from there right? Its date night so I won't be back on till morning if I play my cards right lol

Sorry to say but most guys don’t have calibration plates. They just don’t care because the higher the results the better they personally look as head porters. If I port your heads and they flow 300 and he ports your heads and he get 320 who do you think most guys are going to have port their heads.

L

I would look for another bench too. Either that or someone forgot to screw a spark plug in the spark plug hole. Lol. That’s the reason way I always flow and give before and after numbers.

I did have them flowed a year or so ago (same bench but possibly different operator and conditions idk)after opening the pinch a bit and some quick clean up. Not sure if I still have the numbers saved somewhere. The port seemed pretty fast. If I remember correctly they were like [email protected] but didn't leave the 250 range from .500-.700. So I brought them home with the idea that I would open the pinch a bit more, try and slow them down a bit and play with the short turn. The exhaust #s were pretty typical so I went through them again as well. I was expecting no more than mid 270 on the intake and maybe 200 for the exhaust. I'll figure out what's goin on this week.

I hate to tell you this but everyone thinks opening up “the pinch” is head porting. Wrong!!!! It’s the easiest to see and the easiest to open up but to port you have to straighten the common wall, widen the short-side, raise the roof, shape the short-side, chamber work, proper valve angles, control airspeed at the shortside so air can navigate the turn (if not air shoots the turn and disrupts clean air coming down the backside of the valve).

Last edited:

I hate to tell you this but everyone thinks opening up “the punch” is head porting. Wrong!!!! It’s the easiest to see and the easiest to open up but to port you have to straighten the common wall, widen the short-side, raise the roof, shape the short-side, chamber work, proper valve angles, control airspeed at the shortside so air can navigate the turn (if not air shoots the turn and disrupts clean air coming down the backside of the valve).

I hear ya. Yeah I wouldn't call opening the pinch porting lol. Like you said it's easy so it was done along with most everything you mentioned. I am gonna get to the bottom of what's goin on and post those numbers good or bad. I need to know the good, the bad, and the ugly for my own growth here.

My guy wants to flow them again. I am going to try and drill him about calibration and anything else that could be a factor. I have heard there is a guy a couple towns over with a bench. I will try him next.

PRH

Well-Known Member

The .100, .200, .300 numbers are all you need to look at to know the numbers are “highly suspect”.

With that style of head, most of time the c/d at .100 lift is in the 70-75% range.

That [email protected] lift is 98% on the intake.

The [email protected] lift on the exhaust is showing 113%(13% more than what area is available).

Not gonna happen.

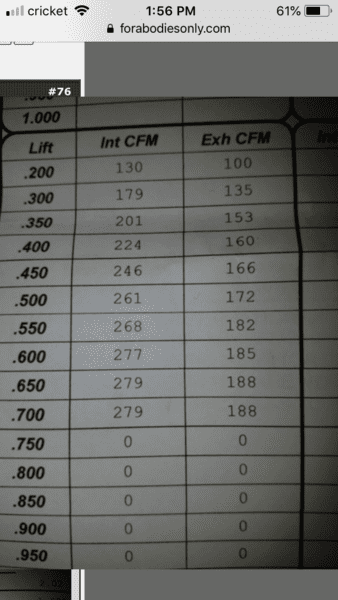

These were posted earlier in this thread for a cnc ported Head with a valve job.

Do you think you did enough more porting to your heads to beat the cnc heads by 25cfm?

With that style of head, most of time the c/d at .100 lift is in the 70-75% range.

That [email protected] lift is 98% on the intake.

The [email protected] lift on the exhaust is showing 113%(13% more than what area is available).

Not gonna happen.

These were posted earlier in this thread for a cnc ported Head with a valve job.

Do you think you did enough more porting to your heads to beat the cnc heads by 25cfm?

Last edited:

The .100, .200, .300 numbers are all you need to look at to know the numbers are “highly suspect”.

With that style of head, most of time the c/d at .100 lift is in the 70-75% range.

That [email protected] lift is 98% on the intake.

The [email protected] lift on the exhaust is showing 113%(13% more than what area is available).

Not gonna happen.

The whole thing seemed kinda wonky to me. No one is moving that kinda air at .100 with that type of head, let alone through the entire range. I should know more in the next week or so. If this isn't an operator error I wonder how long this has been an issue. I hope to go in tomorrow and find out a simple mistake was made. I have not had much time around benches to know what the issue could be other than it could be lots of things lol. At any rate they will see another bench. Gonna drive me bonkers till I get some good numbers. Good meaning honest lol. I thank you guys for the responses.

I somehow missed part of your response...Nope definitely don't think mine are better or that I did a better job. Not likely... probably should have waited to put numbers up. I was hoping they would be close to those though. I would love to believe that I did a better job in my shop at home but I am not that arrogant/ignorant lol. Shouldn't be hard to figure out what's going on.

Last edited:

Well he thinks he found the problem. He pulled the head off this morning to find they were flowed with a 4.5" bore. He was a little embarrassed. Pretty soft on the low/mid. Probably should have left them alone. This was my second pair of heads I have worked on. First set were some iron J heads I had. I got these cheap enough that I wasn't afraid to grind on them.

.100 66/48

.200 120/96

.300 168/131

.400 225/160

.500 258/176

.600 270/182

.700 276/186

Thanks for the input guys.

.100 66/48

.200 120/96

.300 168/131

.400 225/160

.500 258/176

.600 270/182

.700 276/186

Thanks for the input guys.

MOPAROFFICIAL

Oogliboogli

Slaughtered them fuckers.lolWell he thinks he found the problem. He pulled the head off this morning to find they were flowed with a 4.5" bore. He was a little embarrassed. Pretty soft on the low/mid. Probably should have left them alone. This was my second pair of heads I have worked on. First set were some iron J heads I had. I got these cheap enough that I wasn't afraid to grind on them.

.100 66/48

.200 120/96

.300 168/131

.400 225/160

.500 258/176

.600 270/182

.700 276/186

Thanks for the input guys.

Post pics....hopefully it is just shaped wrong and can be saved. Sometimes when people who are novices screw up and grind one side of the port to death 'cuz it looks right to do that' you can still save it, sometimes...by turning the head into an all-out effort and lay the rest of it back the same , kinda...

Let's see what you dorked.

The .300 lift is in the toilet

PRH

Well-Known Member

Must have created a leak with the bigger bore adapter.

Depending on what you’re trying to do with the heads, more work on them may or may not be worthwhile.

Has the valve job been done yet?

A few pics of what’s done might be helpful.

Depending on what you’re trying to do with the heads, more work on them may or may not be worthwhile.

Has the valve job been done yet?

A few pics of what’s done might be helpful.

No valve job. I didn't really wanna post those numbers but I said I would lol. I won't have the head back until next Monday. Lots more reading and researching in my future. Kinda don't wanna touch anything ever again without easy access to a bench and someone who knows how to run it. Can get real spendy flowing a head every time ya make a small change. Kinda sucks, I didn't feel I hogged as much as the numbers seem to indicate. Don't really have a solid build planned yet. Any rate, is what it is for now.

As we all know We have the Edelbrock head, the OLD ProComp head that became the SpeedMaster head to escape their reputation, then SideWinder, ProMax, and several others. Edelbrocks at one time worried about quality control but threw that out the window. I know the ProMax comes from across the Pond but the critical work is done in-house. I hear good things about the Sidewinders but never touched a set. I threw a set of heads that I ported many years ago over the weekend that were on my Duster with a .520 lift Racer Brown cam and ran 10.20's. I was going to touch them up and put them on my 360 but was thinking I put 2.05 valves in them. (wrong) I forgot Matt bought those heads. So I ordered some new 2.05 ferrara valves but for now I'm swiping my BEST set I ever ported that my son BORROWED and fell in love with. I never poured one to see what the runner cc is but plan on checking one intake runner. Well back to the flow number on the set with 2.02 valves in them. They were up to 291cfm at .600 and at .650 started backing up and you could here it. Even though They were nicely ported and "the pinch" widened an tubed but not ported to touch the tube Like I do now air-speed PEGGED my meter at 401 FPS (foot per second) and the pinch and short-turn. For now they go back on the shelf till I get time and the 2.05 valves come. They worked GREAT with the small .520 lift Racer Brown but this engine has a roller cam. I can't wait to see what the TrickFlow heads can put out with a bigger valve and a little bit of love.

PRH

Well-Known Member

Properly reworking the seats can pick the .200, .300, .400 numbers up.

Did you port the whole head, or is there an untouched pair of ports that could be tested to get somewhat of a baseline set of numbers.

Did you port the whole head, or is there an untouched pair of ports that could be tested to get somewhat of a baseline set of numbers.

Hey look here have just bought a pair of speedmaster heads LA

https://www.forabodiesonly.com/mopa...ome-advice-sb-360-cam-selection.384223/page-3

New in here need some advice SB 360 Cam selection

https://www.forabodiesonly.com/mopa...ome-advice-sb-360-cam-selection.384223/page-3

New in here need some advice SB 360 Cam selection

I got a set of the 35 percent off heads in Indio california being hand ported.....wont be done until this fall...also there is a set of eddy heads there for the same thing...both using the same 2.055 intake and pac valve spring..ported by the same person....checked on the same flow bench....could be interesting....

-