JAndrea

Well-Known Member

Long post… and my first engine build (aside from a motorcycle engine), startup, and dyno.

After getting it hooked up to the dyno, the motor started right up after one second and it sounded amazing... that was a relief and a great feeling. After about 4 seconds, we saw that my 750 DP HO carb was overflowing. I had forgotten to set the float levels. No big wup. He (Ron) shut it down immediately and bolted his 750 DP on. Again, it started right up. breakin was about 20 minutes. All vitals looked excellent... no issues, except for.... yes... omg yes... and I just knew it was going to happen.... the dreaded rear main seal leak.

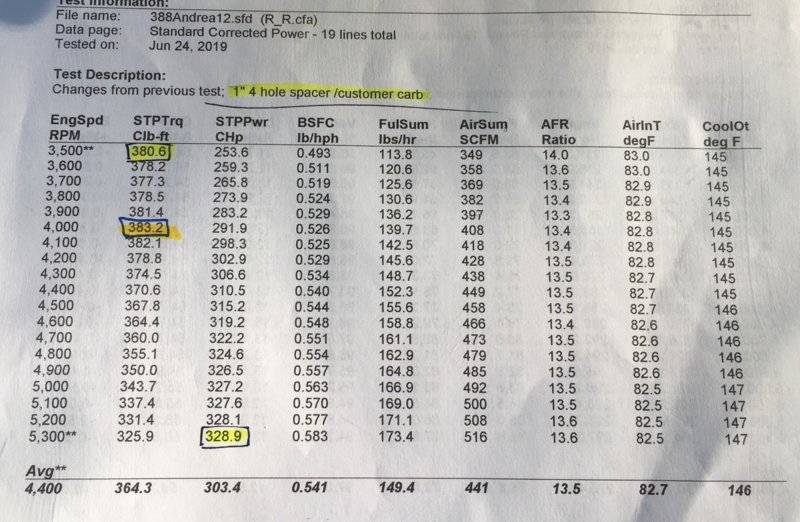

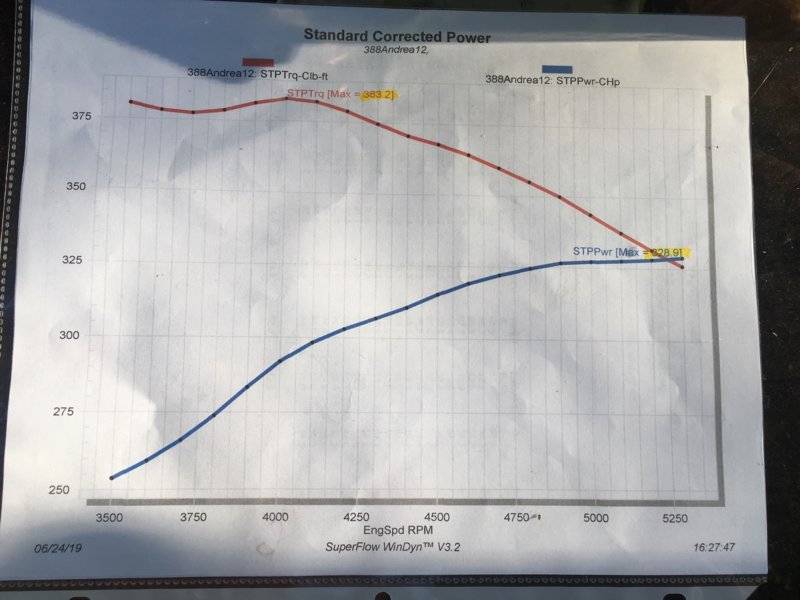

Ron hooked up a PCV hose to slow the leak during the pulls and it made a big difference in the leak flow. So, we then proceeded to the pulls. Various pulls and timing changes found 34 degrees advance to be the optimum for the setup. We also added a 1” carb spacer, which the engine definitely liked. Air fuel ratio seemed right on as well. Plugs look great upon inspection.

After doing about 12 pulls, including setting my float levels on my AED 750 HO HP carb andmounting that (which it liked)... I have to say… I was only going for old school horsepower, but I’m pretty disappointed. Never even came close to 400TQ and 338HP was the best it could make. Granted, I have no problem with those numbers in general, but I didn’t pay the extra $, and take so much meticulous time, for stock 383 figures. I was thinking it would come in around 400hp, with a chance of a little more. Even with the 906 heads, I thought I had pretty realistic expectations.

Specs and work:

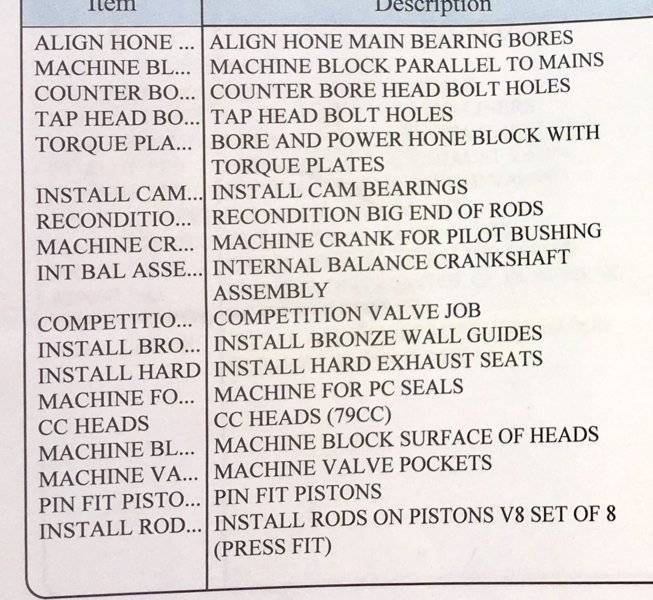

block

1968 383 magnafluxed and bored to 4.28”

Zero decked

Align honed

Machined block parallel to mains

Trq plated

Int Balanced crank assembly

Block, heads, crank, pistons all mated and matched during machining process by engine builder.

Crank

Forged, ground, reconditioned crank.

Heads

#906 iron heads completely redone (NOT ported)

Int: 2.14

Exh: 1.81

Milled to 79cc

.039” head gask

Hardened seats

Springs - Not sure on these, but I’ll try to find out

Stamped, stock rockers

I don’t know for sure, but i think I’m around 9.6:1 CR

Ignition

Electronic Distributor - MOP440-431 Mopar Perf w/MSD 6 AL (dyno-owned)

34 degrees was found to be optimum

Pistons

Flat top w/valve reliefs cut by builder

Forged aluminum, Speed Pro (L-2315NF 30) 4.28”

Moly rings

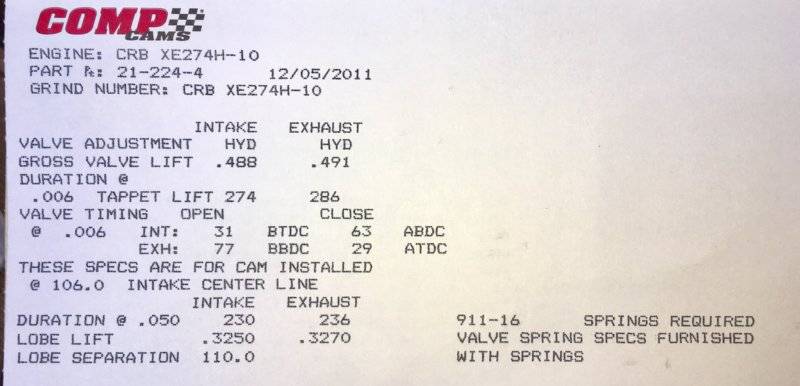

Cam

Hyd FT

COMP Cams Xtreme Energy Camshafts 21-224-4

274/286, Lift .488/.491

Degree’d by me

Lifters

COMP Cams High Energy Hydraulic Lifters 822-16

Intake

Performer RPM

Carb

Holley AED 750 DP HO HP

Jets

P: 74

S: 82

Powervalve: 6.5

Dyno Headers

1 ¾” to match what I plan to use

I did the tolerance checks and assembly on the entire motor, except the heads. After being “done” the heads came back to me without too many details, which I should have asked for right away.

Anyway, Ron found no strange sounds, etc.. during the dyno session and said everything looked great, it must just be a “mild” motor. Ron has dyno’d over 10K motors in 30 years. We also pulled the valve covers to make sure the cam and valves were behaving.

I did screw up and mix 3 gallons of 98 octane race gas and 1 gallon non-oxy unleaded… as opposed to the other way around… 1 gall race gas and 3 gall unleaded). I don’t think running race gas quality through a mild compression ratio motor would have set me back too much though, but not sure.

When I got home, I drained and checked the oil, let it sit for a while... and it looked just fine, no metal, etc. Super clean actually. Then I cut open the oil filter and checked the paper. There was definitely the black moly lube residuals and some tiny flakes in the oil. As far as the paper… once I cut that out and squeezed it in my vice, there were definitely some flakes, but not excessive. I brought it to the builder, who spec’d my components, and he said the filter “looks pretty typical”. He thought I should have hit 390hp or so, but didn’t give any ideas on why I didn’t hit that mark.

I then measured the pushrod height (dial indicator) on #1 and #7, and found .327” and .325” for int/exh… when multiplying by 1.5 rocker ratio.. lift was exactly where it was supposed to be according to cam card.

I’d appreciate any ideas, comments, advice, etc… if this is all I’ll get for hp and tq, that’s cool. It’s just a hobby car, not a racer… but if anybody can think of some things to check… let me know.

I’ll soon be doing a leakage test on all cyls, and going after that rear main seal leak.

After getting it hooked up to the dyno, the motor started right up after one second and it sounded amazing... that was a relief and a great feeling. After about 4 seconds, we saw that my 750 DP HO carb was overflowing. I had forgotten to set the float levels. No big wup. He (Ron) shut it down immediately and bolted his 750 DP on. Again, it started right up. breakin was about 20 minutes. All vitals looked excellent... no issues, except for.... yes... omg yes... and I just knew it was going to happen.... the dreaded rear main seal leak.

Ron hooked up a PCV hose to slow the leak during the pulls and it made a big difference in the leak flow. So, we then proceeded to the pulls. Various pulls and timing changes found 34 degrees advance to be the optimum for the setup. We also added a 1” carb spacer, which the engine definitely liked. Air fuel ratio seemed right on as well. Plugs look great upon inspection.

After doing about 12 pulls, including setting my float levels on my AED 750 HO HP carb andmounting that (which it liked)... I have to say… I was only going for old school horsepower, but I’m pretty disappointed. Never even came close to 400TQ and 338HP was the best it could make. Granted, I have no problem with those numbers in general, but I didn’t pay the extra $, and take so much meticulous time, for stock 383 figures. I was thinking it would come in around 400hp, with a chance of a little more. Even with the 906 heads, I thought I had pretty realistic expectations.

Specs and work:

block

1968 383 magnafluxed and bored to 4.28”

Zero decked

Align honed

Machined block parallel to mains

Trq plated

Int Balanced crank assembly

Block, heads, crank, pistons all mated and matched during machining process by engine builder.

Crank

Forged, ground, reconditioned crank.

Heads

#906 iron heads completely redone (NOT ported)

Int: 2.14

Exh: 1.81

Milled to 79cc

.039” head gask

Hardened seats

Springs - Not sure on these, but I’ll try to find out

Stamped, stock rockers

I don’t know for sure, but i think I’m around 9.6:1 CR

Ignition

Electronic Distributor - MOP440-431 Mopar Perf w/MSD 6 AL (dyno-owned)

34 degrees was found to be optimum

Pistons

Flat top w/valve reliefs cut by builder

Forged aluminum, Speed Pro (L-2315NF 30) 4.28”

Moly rings

Cam

Hyd FT

COMP Cams Xtreme Energy Camshafts 21-224-4

274/286, Lift .488/.491

Degree’d by me

Lifters

COMP Cams High Energy Hydraulic Lifters 822-16

Intake

Performer RPM

Carb

Holley AED 750 DP HO HP

Jets

P: 74

S: 82

Powervalve: 6.5

Dyno Headers

1 ¾” to match what I plan to use

I did the tolerance checks and assembly on the entire motor, except the heads. After being “done” the heads came back to me without too many details, which I should have asked for right away.

Anyway, Ron found no strange sounds, etc.. during the dyno session and said everything looked great, it must just be a “mild” motor. Ron has dyno’d over 10K motors in 30 years. We also pulled the valve covers to make sure the cam and valves were behaving.

I did screw up and mix 3 gallons of 98 octane race gas and 1 gallon non-oxy unleaded… as opposed to the other way around… 1 gall race gas and 3 gall unleaded). I don’t think running race gas quality through a mild compression ratio motor would have set me back too much though, but not sure.

When I got home, I drained and checked the oil, let it sit for a while... and it looked just fine, no metal, etc. Super clean actually. Then I cut open the oil filter and checked the paper. There was definitely the black moly lube residuals and some tiny flakes in the oil. As far as the paper… once I cut that out and squeezed it in my vice, there were definitely some flakes, but not excessive. I brought it to the builder, who spec’d my components, and he said the filter “looks pretty typical”. He thought I should have hit 390hp or so, but didn’t give any ideas on why I didn’t hit that mark.

I then measured the pushrod height (dial indicator) on #1 and #7, and found .327” and .325” for int/exh… when multiplying by 1.5 rocker ratio.. lift was exactly where it was supposed to be according to cam card.

I’d appreciate any ideas, comments, advice, etc… if this is all I’ll get for hp and tq, that’s cool. It’s just a hobby car, not a racer… but if anybody can think of some things to check… let me know.

I’ll soon be doing a leakage test on all cyls, and going after that rear main seal leak.

Last edited: