You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

<<<<<430 cube small block mopar build>>>>>

- Thread starter DJVCUDA

- Start date

-

Got some work done this weekend - the bearing clearances needed to be checked.

Got the rods cleaned up piece by piece in the parts washer and ready to be torqued to spec.

ARP lubed the threads and the shank of each bolt

ARP's stretch gauge confirmed the 75 ft/ lbs of torque was good for .004-.005 stretch on the bolts.

At 75 ft/lbs they were all reading between the .004 and .005 recommended

after they were torqued the ID was checked to spec - we had 7 of them 2 tenths large and one 3 tenths large - they were all very consistent and uniform rods.

Got the rods cleaned up piece by piece in the parts washer and ready to be torqued to spec.

ARP lubed the threads and the shank of each bolt

ARP's stretch gauge confirmed the 75 ft/ lbs of torque was good for .004-.005 stretch on the bolts.

At 75 ft/lbs they were all reading between the .004 and .005 recommended

after they were torqued the ID was checked to spec - we had 7 of them 2 tenths large and one 3 tenths large - they were all very consistent and uniform rods.

robert 68 cuda

Well-Known Member

i cant weight to see the dyno number hope ever thing works out great for you.

moper

Well-Known Member

Dave, was it honed with a plate?

moper

Well-Known Member

Ah. Cool. I didn't see the plate in the picture and I know when I measure mine they are out of round up top without anything bolted to the deck surfaces.

moper

Well-Known Member

RIGHT... I forgot about that block...lol!

imager

Well-Known Member

DJVCUDA Just wanted to thank you for this thread great info and pics...

HawaiiDuster

Well-Known Member

Any new updates and pics......especially pics  Great job on this build thread

Great job on this build thread  rayer:

rayer:

HawaiiDuster

Well-Known Member

Sorry forgot you were on that end of the US. Hope things aren't too bad for you. I sent Rod an email to check on the status of his assemblies.

Rat Patrol

Well-Known Member

subscribed

SRT_DSTRHOLC

Well-Known Member

How much was the kit meaning pistons, rods, and crank?

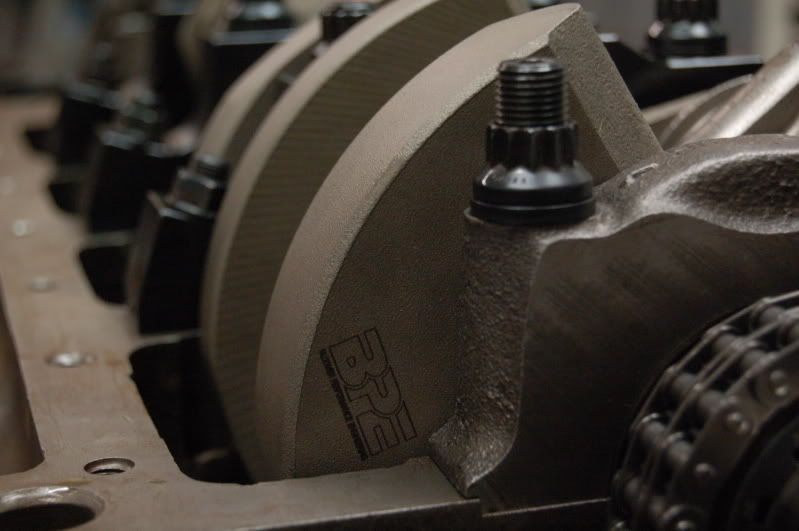

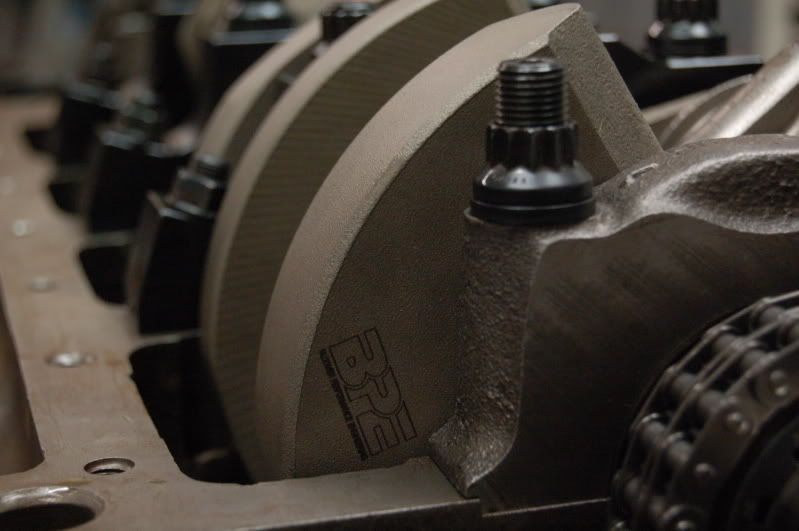

Set the end play - It;s right at .005 right where it needs to be - another testament to the BPE crank being dead on balls accurate!

Need to check the clearance of the counterweights?

Need to get in to a tight spot?

Need a flexable feeler gauge?

measure a zip tie ( this one was .060 and the crank spun with it between the counterweight and the webbing.

Rod clearance was right on at .016 - quality rods and quality cranks sure make assembly easy!!!

Badart

Senior Member

That quality of work and attention to detail is rare. Great job and thanks for sharing.

HawaiiDuster

Well-Known Member

Looking awesome! Can't wait to get my kit when I get back to Vegas :blob:

grimreaper

Cross Member

Have you got any updates on this build for us? Anxiously waiting here......

Thanks!

Thanks!

Just a quick update - Been working a ton, but have managed to get over to work on things a few times and have not updated.

Just about ready to balance after checking and re-checking everything - the shop was impressed with the BPE setup to say the least. They started recommending them to guys inquiring about SBM setups. The fit and finish was better then anything they have touched before in this price range.

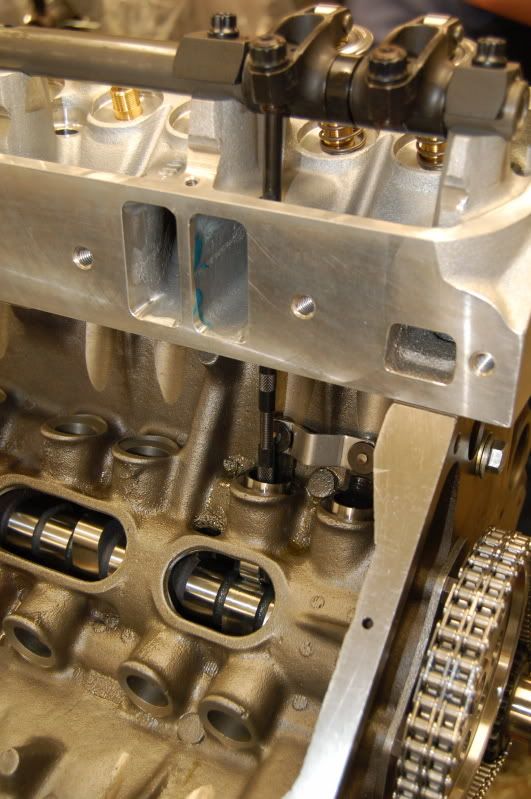

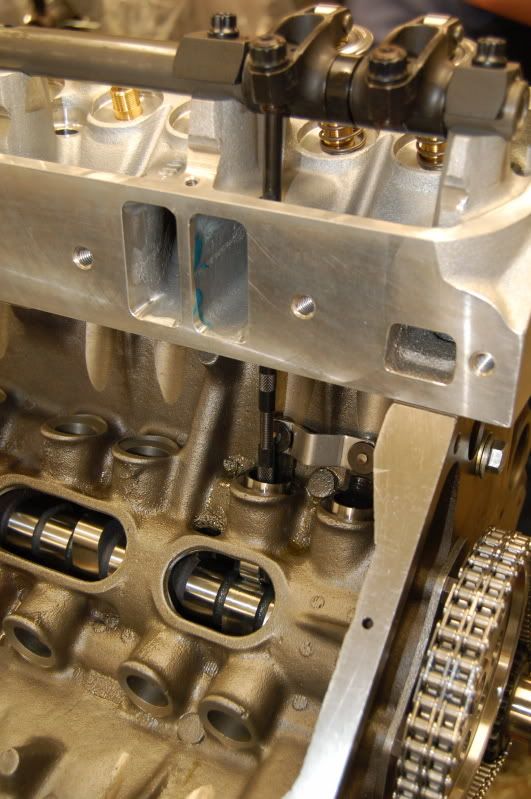

Slid both cams in and checked with both heads, the PTV, Radial clearance, and pushrod length was all checked and we are all set.

Radial clearances was checked with clay, Rod's pistons have a ton even with the 2.055 intakes on the ported set of heads, considering the rock of the piston as well.

Pushrods are all at 7.600 - they are all 7.595" long at the last point we checked them so I will be ordering them soon.

Just about ready to balance after checking and re-checking everything - the shop was impressed with the BPE setup to say the least. They started recommending them to guys inquiring about SBM setups. The fit and finish was better then anything they have touched before in this price range.

Slid both cams in and checked with both heads, the PTV, Radial clearance, and pushrod length was all checked and we are all set.

Radial clearances was checked with clay, Rod's pistons have a ton even with the 2.055 intakes on the ported set of heads, considering the rock of the piston as well.

Pushrods are all at 7.600 - they are all 7.595" long at the last point we checked them so I will be ordering them soon.

darndart

Well-Known Member

You stated that you started with a 79 X block. Is that a production 360 block? Aftermarket 340 block?

What will the compression ratio be?

What will the compression ratio be?

damn thats a nice engine.....so whats something like this cost? i want one...

SheSaid

Mopar/Jeep Guy

Any more progress? Updates? I think I have read this forum more than 20 times. Keep up the good work!

-