So I got a 6.1 from a buddy of mine and it's very clean but was partially dismantled for verification. From what I read I cannot re-use the head bolts. I understand. I was going to remove a rod cap and main to verify but was told to ask because some say the Bolts cannot be reused and worse yet the rods are crack rods meaning no resizing. So if I were to even attempt to put ARP as on older engines you can't because cannot resize rods? So what, take a chance and just leave them as is and just re-assemble the heads? Any input would be greatly appreciated, Thanks a Bunch

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

6.1 Hemi Internals.

- Thread starter m79ded

- Start date

-

DionR

Well-Known Member

I think Mopar says to replace head and crank bolts. But....

Be careful of the terminology. The old 2.2/2.5 FWD turbo stuff used torque to yield head bolts that actually stretch. The new Hemi stuff is turn to torque (I think) and is completely different. The FWD stuff used a degree of rotation as well, but the bolts are different. The G3 stuff isn't expected to stretch, the FWD stuff was. You didn't use those terms, but I have seen several posts that seem to confuse the 2 and think that because both use a degree of rotation to set the torque, then they must be the same.

In addition, I think the rods are different in that the rod bolt threads into the rod rather than are pressed in with a nut. So replacing the rod bolts with ARP isn't about pressing new bolts in and then resizing the rods, it's just about tossing the old and screwing in new ones.

I think the "replace all bolts" mantra is more about dealerships (and the manufacturer) CYA.

Be careful of the terminology. The old 2.2/2.5 FWD turbo stuff used torque to yield head bolts that actually stretch. The new Hemi stuff is turn to torque (I think) and is completely different. The FWD stuff used a degree of rotation as well, but the bolts are different. The G3 stuff isn't expected to stretch, the FWD stuff was. You didn't use those terms, but I have seen several posts that seem to confuse the 2 and think that because both use a degree of rotation to set the torque, then they must be the same.

In addition, I think the rods are different in that the rod bolt threads into the rod rather than are pressed in with a nut. So replacing the rod bolts with ARP isn't about pressing new bolts in and then resizing the rods, it's just about tossing the old and screwing in new ones.

I think the "replace all bolts" mantra is more about dealerships (and the manufacturer) CYA.

@PROSTOCKTOM carries some nice Molnar GenIII rods. If I were considering power adders in the future, I would go ahead and upgrade.

I did a 5.7 awhile back. Put ARP bolts in the bottom end. Did not change crank or rod run out. But, as Garret pointed out, if you plan to power add or boost, put a drop in/no balance required piston/rod set now while it's apart. On the head bolts, they are indeed torque to angle. But my understanding is they are still a one time use. Same for the lower end hardware. I have an Eagle 5.7 that I changed the reluctor wheel on to run the MSD Hemi 6 ignition. I re-used all the stock hardware. Ran the dogshit out of it with no failure. Your results may vary.......

Thanks for the info and especially MSD 6 Hemi, so the MSD system needs the earlier type of reluctor found on like the 1st 5.7 and 6.1? I was also looking into other engine management scenarios I was told Holley is good. Excuse my ignorance but this is my 1st dive into the modern stuff and I'm learning as I go along. All of you Garret and Dion make great points and glad y'all chimed in I'm not planning boost for now but you never know and since it's apart perhapa why not take advantage of it. It's presently a street driven 10.50 Duster but not a tame animal by no means and was looking into taming it and installing a supercharger be it a H/C style or a Pro Charger would be nicer tamer power.I did a 5.7 awhile back. Put ARP bolts in the bottom end. Did not change crank or rod run out. But, as Garret pointed out, if you plan to power add or boost, put a drop in/no balance required piston/rod set now while it's apart. On the head bolts, they are indeed torque to angle. But my understanding is they are still a one time use. Same for the lower end hardware. I have an Eagle 5.7 that I changed the reluctor wheel on to run the MSD Hemi 6 ignition. I re-used all the stock hardware. Ran the dogshit out of it with no failure. Your results may vary.......

Correct. The Hemi 6 only works with the 32 tooth wheel found in the 03-08 5.7 and all 6.1.Thanks for the info and especially MSD 6 Hemi, so the MSD system needs the earlier type of reluctor found on like the 1st 5.7 and 6.1? I was also looking into other engine management scenarios I was told Holley is good. Excuse my ignorance but this is my 1st dive into the modern stuff and I'm learning as I go along. All of you Garret and Dion make great points and glad y'all chimed in I'm not planning boost for now but you never know and since it's apart perhapa why not take advantage of it. It's presently a street driven 10.50 Duster but not a tame animal by no means and was looking into taming it and installing a supercharger be it a H/C style or a Pro Charger would be nicer tamer power.

I have no experience with the coils you mention. I have seen dyno numbers comparing stock to MSD. IIRC, it was literally a horse apiece. The number going to MSD. The stock coils are really pretty decent.BTW are NP Boosted coils any good or just get the OEM ones?

racerjoe

Well-Known Member

I just installed an early 5.7 in my car. I tore it down and pretty much put the bottom end right back together with all the same parts except the rings. The bearings looked like they had just come out of a box. I did, however, replace the head bolts. They are only $20 per side on rock auto. Honestly, I only ordered them because I was ordering a bunch of other parts. Otherwise I would have just reused the old bolts. I think it's just another way for dealers to make money and cover their ***.

racerjoe

Well-Known Member

I'll throw something out there for everyone to ponder. I'm sure not everyone has been up close and personal with a locomotive engine, so I'll explain. In particular, GE loco engines use huge head studs as you can imagine. They have a tool that stretches the stud and you simply run the nut down to a very minimal torque, practically hand tight. Then the stretching tool is released and now the head is torqued down. These studs aren't one time use. Perhaps the argument could be the stress isn't being put onto the thread while the nut is being tightened down, but at the end of the day its still stretching the bolt.

There have been plenty of people reuse head bolts on LS engines with tons of boost without problem. It all gets down to personal opinion. If you are building a car for tons of power, chances are you aren't using factory replacement head bolts.

There have been plenty of people reuse head bolts on LS engines with tons of boost without problem. It all gets down to personal opinion. If you are building a car for tons of power, chances are you aren't using factory replacement head bolts.

I don't particularly agree with this. If the threads on the bolt are permanently deformed, they would tear the threads on the block on the way out.Yield, by definition, means the part has been permanently deformed.

You don't have to agree. I'll just refer you to "machine design" where you can study up on fastener stresses.

The shank of the bolt is elongating. Not all fasteners were talking about are necessarily torque to yield. I'd tend to agree that a bolt that's not torque to yield can generally be reused. However it possible that the torque specs on traditional fasteners are based on yield point in which case it's still torque to yield.

Many a broken off stud in an engine block or cylinder head. Just Google how do I get this broken off bolt out...

The shank of the bolt is elongating. Not all fasteners were talking about are necessarily torque to yield. I'd tend to agree that a bolt that's not torque to yield can generally be reused. However it possible that the torque specs on traditional fasteners are based on yield point in which case it's still torque to yield.

Many a broken off stud in an engine block or cylinder head. Just Google how do I get this broken off bolt out...

it has alot to do with the metallurgy of the hardware and thermal cycling. ARP studs aren't "torque yield', and reusable The FSM shows torque yield mains but no notes on not reusing them and are definitely a different grade metal .

DionR

Well-Known Member

Just because the torque spec includes a 90 degree turn doesn't make the bolts "torque to yield".

The old FWD turbo head bolts were torque to yield and included a visual that showed if the threads were elongated the bolt was junk, but otherwise could be used again.

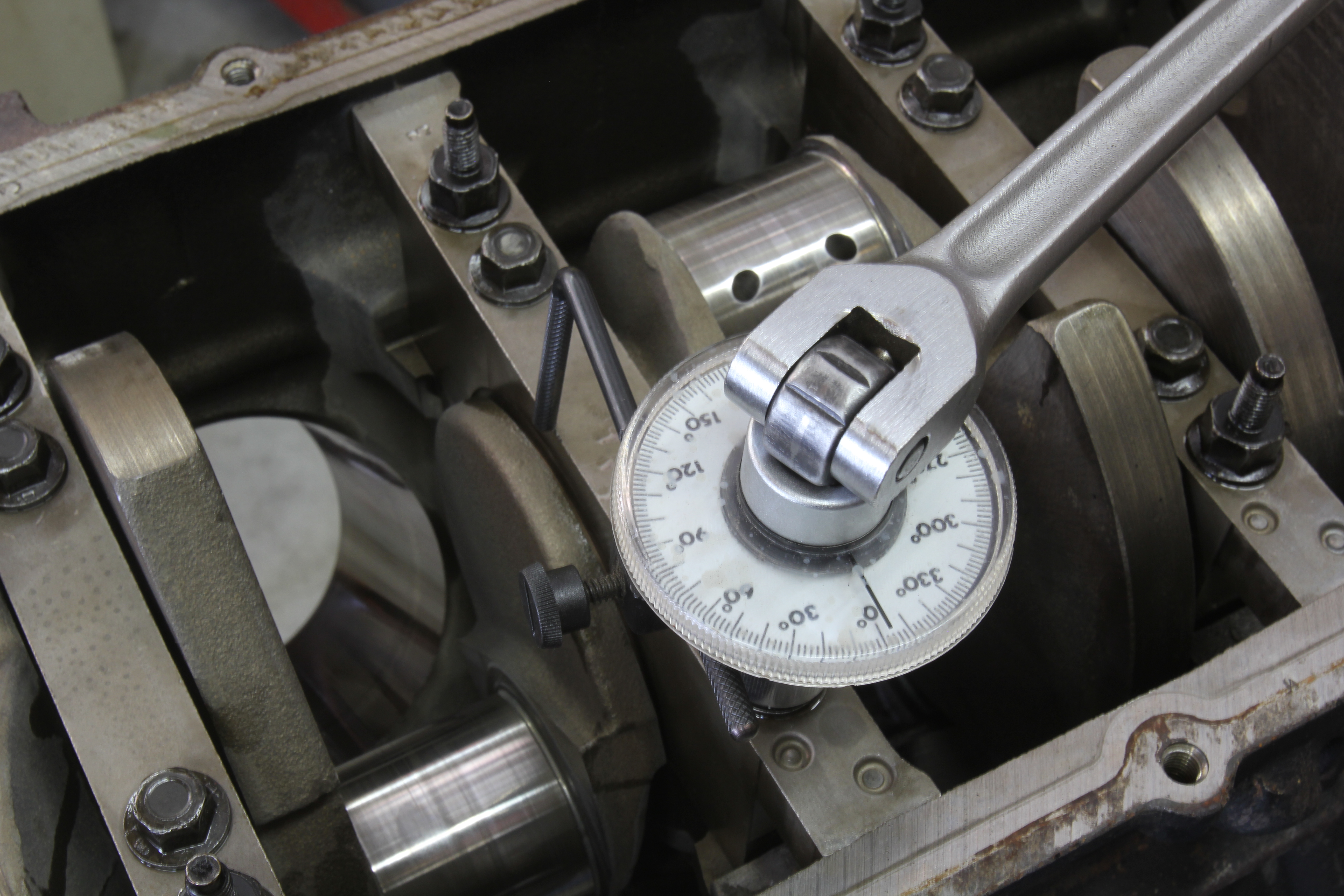

This is similar to what I remember seeing when I was messing with those motors:

Note that it says to replace them only when the bolt shows it is necked down or elongated.

The service manual for a newer Challenger I just checked doesn't have any of that info. Could be because they expect the bolts to be replaced every time so why worry about it. But I think it is because the bolts aren't designed to stretch because they are a "torque to angle" bolt instead. Completely different.

Per Fel-Pro: "Torque-to-angle bolts are fasteners that are tightened to a specific amount of rotation or degrees to ensure the proper amount of clamp load is applied."

I think the problem is that people assume that if there is a degree of rotation in the torque spec then the bolt must be a "torque to yield" bolt. But it doesn't mean that at all.

The old FWD turbo head bolts were torque to yield and included a visual that showed if the threads were elongated the bolt was junk, but otherwise could be used again.

This is similar to what I remember seeing when I was messing with those motors:

Note that it says to replace them only when the bolt shows it is necked down or elongated.

The service manual for a newer Challenger I just checked doesn't have any of that info. Could be because they expect the bolts to be replaced every time so why worry about it. But I think it is because the bolts aren't designed to stretch because they are a "torque to angle" bolt instead. Completely different.

Per Fel-Pro: "Torque-to-angle bolts are fasteners that are tightened to a specific amount of rotation or degrees to ensure the proper amount of clamp load is applied."

I think the problem is that people assume that if there is a degree of rotation in the torque spec then the bolt must be a "torque to yield" bolt. But it doesn't mean that at all.

DionR

Well-Known Member

Torque to YIELD fasteners are not reusable. Yield, by definition, means the part has been permanently deformed. I don't want to get too technical here but it's more than just money making and CYA.

Note that the above image says they only need to be replaced if the bolt shows elongation. So per Mopar, when they were using those style of bolts, they could be re-used if they didn't show elongation.

When I was doing 2.2 or 2.5 head gaskets, depending on my fiscal strength at the time, I would buy a set of new bolts just so I wasn't worried about being short one or two. But when money was tight I would check the bolts before buying any and re-used them. Never had to do the job twice when there wasn't a deck or head issue.

But since these are torque to ANGLE bolts, it's not apples to apples. Unless someone can show me documentation that calls them torque to yield.

Last edited:

DionR

Well-Known Member

Ask Away! with Jeff Smith: The Truth Behind Torque-to-Yield Fasteners and Torque Angle Fastening - OnAllCylinders

What’s the difference between a torque-to-yield bolt and a torque-angle bolt? I see these bolts used with newer engines. Are they the same thing? I’ve also heard that you’re not …

www.onallcylinders.com

www.onallcylinders.com

-