Boony405hp

Well-Known Member

Hey Lads,

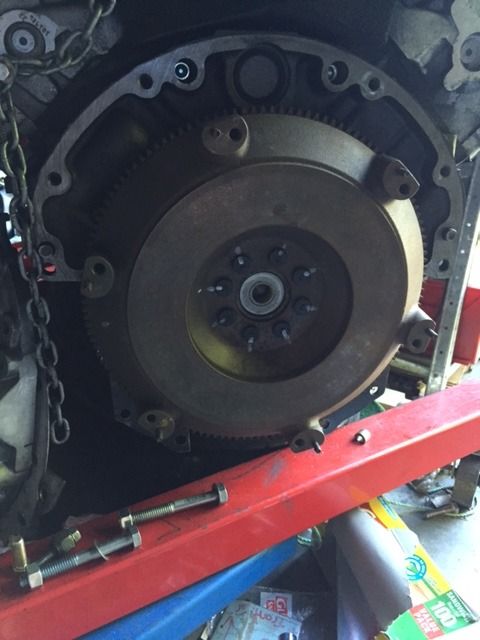

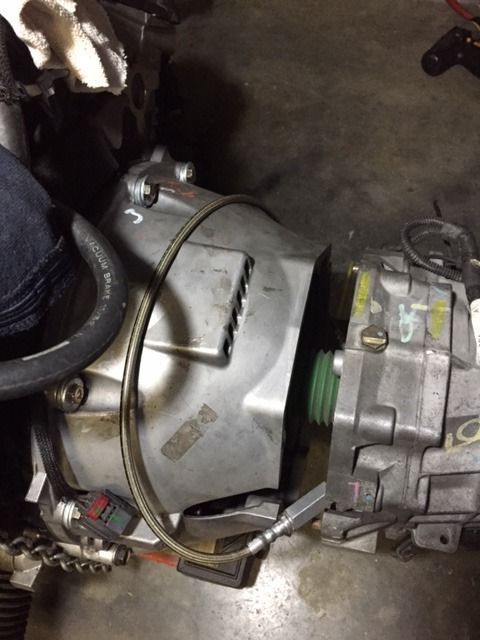

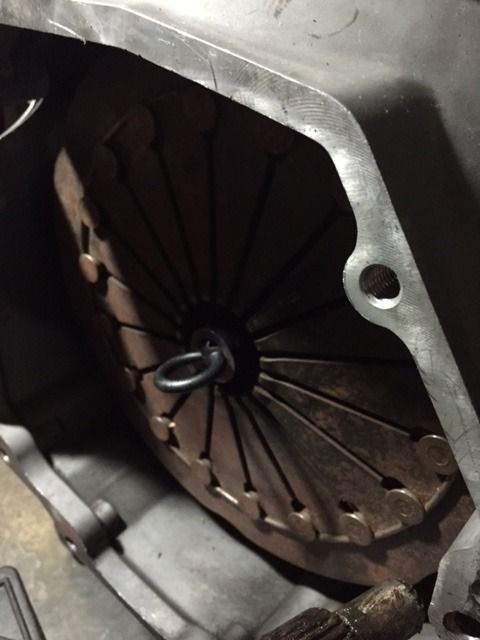

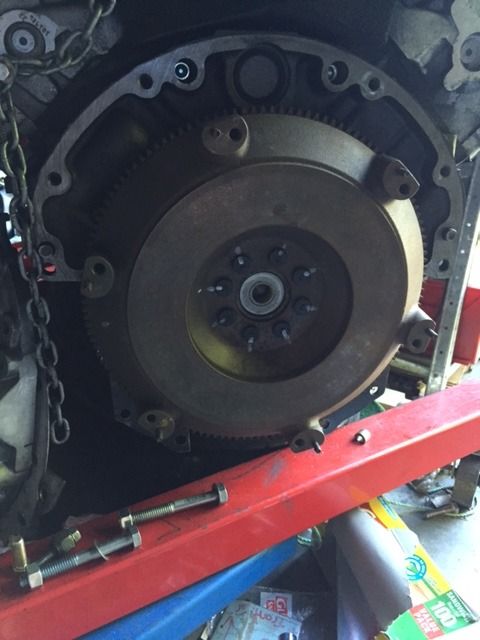

I am trying to install my TR6060 to the back of my 5.7. Everything is factory challenger 6spd: Bellhousing, flywheel, clutch plates, and pressure plate. I have installed the factory Mopar pilot bearing. I used a clutch alignment tool when bolting up both the pressure plate to the flywheel. I made sure that I bolted the second clutch plate around the right way, (one side was marked flywheel side).I can get the transmission input shaft to go through the first clutch plate, but I can't seem to get it to go any further, I try jiggling it and turning it in every perceivable way known to man and it just won't go in! I applied a very light smear of high temp bearing grease on the splines as well. I checked with the clutch alignment tool and it goes in, is there some sort of trick to doing this as it would need to be BANG on to go through two sets of splines. I've spent a few hours on this and still no luck. :banghead:

I am trying to install my TR6060 to the back of my 5.7. Everything is factory challenger 6spd: Bellhousing, flywheel, clutch plates, and pressure plate. I have installed the factory Mopar pilot bearing. I used a clutch alignment tool when bolting up both the pressure plate to the flywheel. I made sure that I bolted the second clutch plate around the right way, (one side was marked flywheel side).I can get the transmission input shaft to go through the first clutch plate, but I can't seem to get it to go any further, I try jiggling it and turning it in every perceivable way known to man and it just won't go in! I applied a very light smear of high temp bearing grease on the splines as well. I checked with the clutch alignment tool and it goes in, is there some sort of trick to doing this as it would need to be BANG on to go through two sets of splines. I've spent a few hours on this and still no luck. :banghead: