Hi all.

After seeing what @soonercruiser had to go through to get proper backup light bulb holders for his chrome housings I thought I would see what I could come up with.

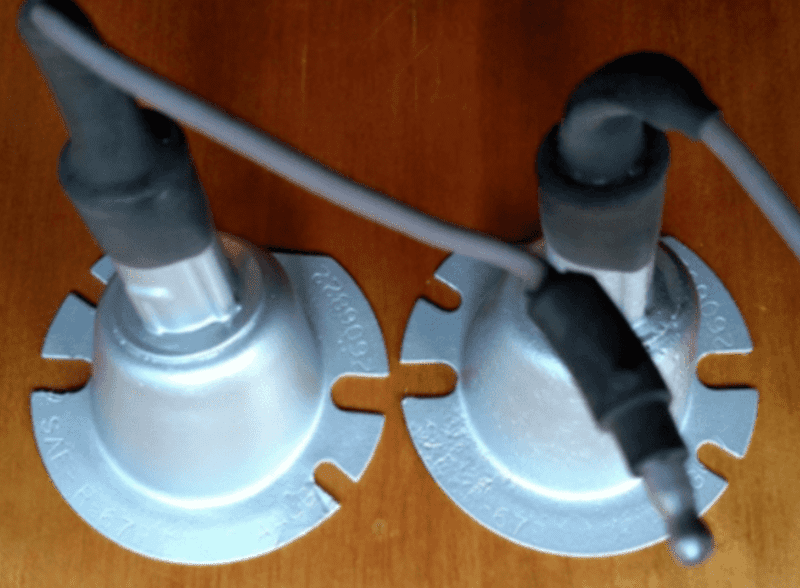

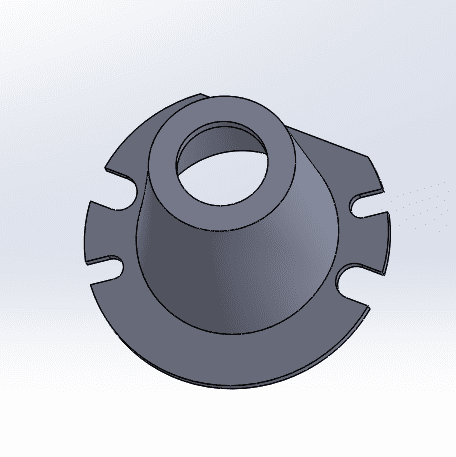

First take (yes I know the tabs are backwards already fixed)

After a couple hours if cad and 3 hours of printing

Bench test of the plastic prototype

Not a proper test as I do not have the lense and gasket. So too much heat leakage.

3 minutes I could smell plastic heating

10 minutes browning of the plastic above the bulb

15 minutes I'm either nose blind or the smell has subsided

20 minutes I ended the test

But it did not catch on fire!

The black lines are ink from a pen I was using to test how soft the plastic got.

It got soft but did not deform.

Hottest temp I saw was 350 deg F

I'm going to make the small tapered end a bit wider and move the walls of the holder out away from the bulb.

My intention is to print this in metal (AL or stainless)

I'll post more results as I get them.

After seeing what @soonercruiser had to go through to get proper backup light bulb holders for his chrome housings I thought I would see what I could come up with.

First take (yes I know the tabs are backwards already fixed)

After a couple hours if cad and 3 hours of printing

Bench test of the plastic prototype

Not a proper test as I do not have the lense and gasket. So too much heat leakage.

3 minutes I could smell plastic heating

10 minutes browning of the plastic above the bulb

15 minutes I'm either nose blind or the smell has subsided

20 minutes I ended the test

But it did not catch on fire!

The black lines are ink from a pen I was using to test how soft the plastic got.

It got soft but did not deform.

Hottest temp I saw was 350 deg F

I'm going to make the small tapered end a bit wider and move the walls of the holder out away from the bulb.

My intention is to print this in metal (AL or stainless)

I'll post more results as I get them.

Last edited: