JAndrea

Well-Known Member

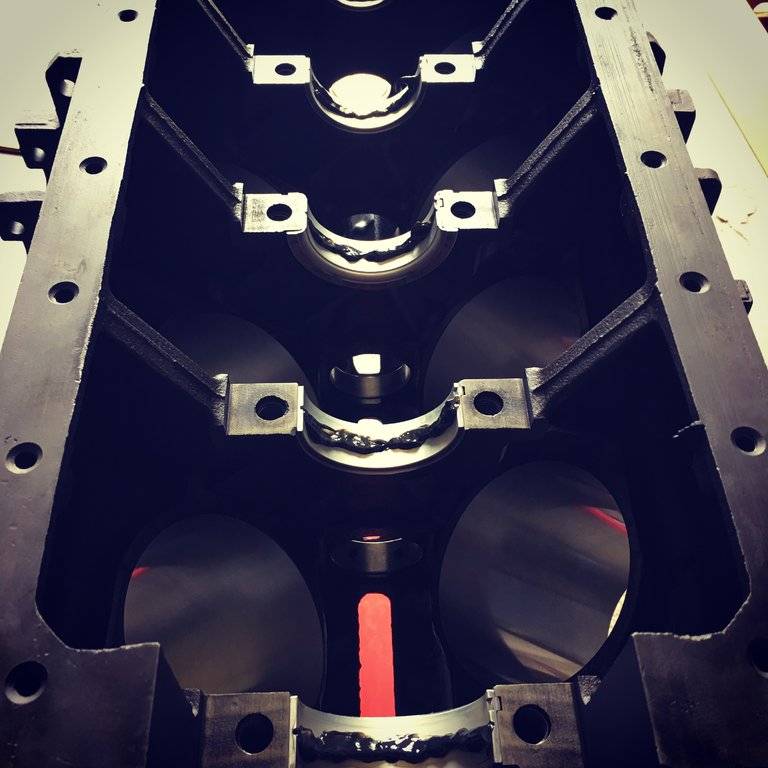

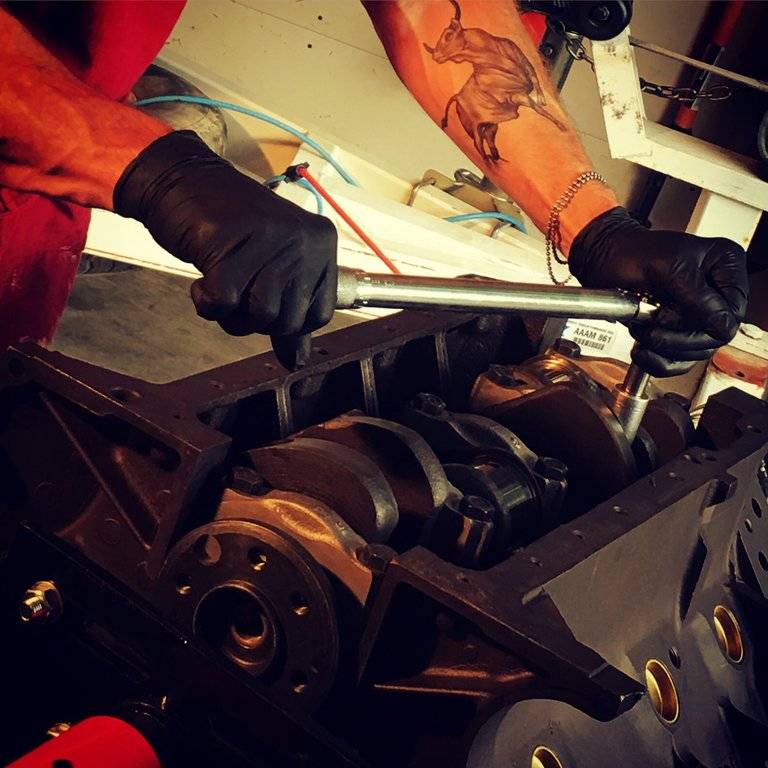

Crank is in! Clearances between .0015 and .002 according to plastigauge. Rotates nicely by hand.

Last edited:

Actually only needed to go .030 over.Engine block magnaflux came out 'all systems go'. Looks like I'll need at least a .040 cylinder overbore to clean them up. I'm thinking I may as well go to .060 out of the gate??

View attachment 1714965481

And the part I've been waiting to order for a long time… the Performer RPM.

View attachment 1715093289

I put the 440 version of that same intake on my car back in 2001. Between the block being decked, the heads being cleaned up and the intake the bolt holes for the intake did not even line up, it sat up too high. I ended up having to remove 0.110" from each face of the intake to get the ports to line up correctly. Just relaying this little tidbit in case you have not checked the alignment of the intake to the heads.

View attachment 1715094502

Yes... the intake alignment has totally been one of my worries. The deck and heads have been milled, so thanks for the reminder. I already installed the heads and torqued them down.

Hopefully I'll be able to do any milling on the intake without removing the heads?

Damn that's a purdy powerplant you have there!