Hi everyone, I'm currently very frustrated because in my quest to replace the axle bearings on my original A body 8 3/4" axle, I nicked the axle seal surface with the cutoff wheel while removing the lock ring. I can't seem to find a speedi sleeve for the axle seal, only ones for the pinion seal. The shaft diameter is 1.5485", and I really don't want to spend $300 on a new set of axles after already spending $85 on new bearings that won't even get used. I think the damage is too deep to polish down, so the only other thing I can think of is to put a little JB weld on there and then polish it down. The only thing about doing that is I imagine it will eventually separate from the axle shaft and cause problems with the seal and bearing. If you were a broke college student in this situation, what would you do?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

8 3/4" Axle Shaft Seal Repair

- Thread starter Chained_360

- Start date

-

royslead

Well-Known Member

You can use the JB Weld, I have repaired sealing surfaces with it; but I don't think you are into the actual sealing surface. The actual sealing surface would be more toward the flange.

Professor Fate

Push the button, Max...

If I were a broke college student, I'd just dress it and run it. You could also put a spacer or shim stock behind the new seal to space it out further past the nick.Hi everyone, I'm currently very frustrated because in my quest to replace the axle bearings on my original A body 8 3/4" axle, I nicked the axle seal surface with the cutoff wheel while removing the lock ring. I can't seem to find a speedi sleeve for the axle seal, only ones for the pinion seal. The shaft diameter is 1.5485", and I really don't want to spend $300 on a new set of axles after already spending $85 on new bearings that won't even get used. I think the damage is too deep to polish down, so the only other thing I can think of is to put a little JB weld on there and then polish it down. The only thing about doing that is I imagine it will eventually separate from the axle shaft and cause problems with the seal and bearing. If you were a broke college student in this situation, what would you do?

View attachment 1715783291

View attachment 1715783292

View attachment 1715783293

If you bought green bearing I would just dress it up and run it.

Hell if you are running stock bearings I would dress it up and run it. JB weld is good but I am thinking you don't need it. Just my 2 cents.

Hell if you are running stock bearings I would dress it up and run it. JB weld is good but I am thinking you don't need it. Just my 2 cents.

Daves69

Well-Known Member

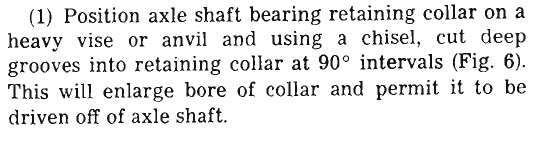

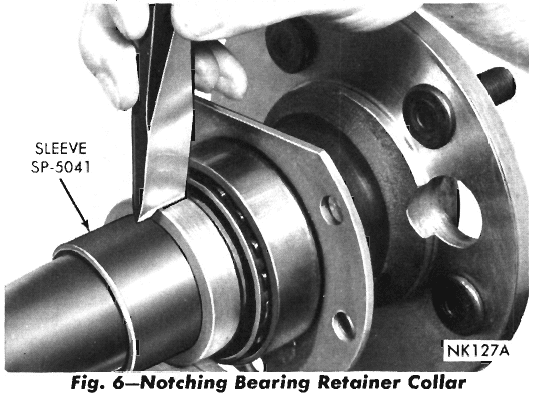

I remove the collars per the FSM just like my friends dad, a NAPA machinist, showed me in my "broke" HS days. He smacked the chisel maybe three times and the collars came right off. While he showed me this, he read me the riot act cause he knew I adjusted the bearings wrong. Started something like "You damn kids don't know....(and so on and so forth).......".

Notice the "sleeve". It's there to protect the axle from mishap..........

Anyway I think I'd try to clean it up. Test fitting the new seal on the shaft may help you decide on whether to press the new bearing on that shaft.

Notice the "sleeve". It's there to protect the axle from mishap..........

Anyway I think I'd try to clean it up. Test fitting the new seal on the shaft may help you decide on whether to press the new bearing on that shaft.

rustycowll69

Well-Known Member

If it is indeed a seal surface, use Belzona. We used to use it to repair bearing surfaces on ship's prop shafts.

my68barracuda

Well-Known Member

You could have it welded then turn down to the correct diameter, but that will get expensive. Using a good - tough epoxy filler can be a long lasting low cost fix. Remember the seal is a polymer-rubber material riding on a smooth steel surface. As long as the filler is harder than the seal it will last a while. Maybe not as long as the steel, but a long time. I would gently smooth the edges of the nick so they are not sharp, then fill the nick and finish the repair so the transition across it is seamless.Hi everyone, I'm currently very frustrated because in my quest to replace the axle bearings on my original A body 8 3/4" axle, I nicked the axle seal surface with the cutoff wheel while removing the lock ring. I can't seem to find a speedi sleeve for the axle seal, only ones for the pinion seal. The shaft diameter is 1.5485", and I really don't want to spend $300 on a new set of axles after already spending $85 on new bearings that won't even get used. I think the damage is too deep to polish down, so the only other thing I can think of is to put a little JB weld on there and then polish it down. The only thing about doing that is I imagine it will eventually separate from the axle shaft and cause problems with the seal and bearing. If you were a broke college student in this situation, what would you do?

View attachment 1715783291

View attachment 1715783292

View attachment 1715783293

It's sometimes used in the aircraft industry, too. Not an approved repair method, but I've seen it used on antique aircraft.If it is indeed a seal surface, use Belzona. We used to use it to repair bearing surfaces on ship's prop shafts.

john-9

Well-Known Member

find an industrial bearing distributor in your area ,, take your axle shaft along with you so they can measure the surface and i am sure they can fix you up with a speedi sleeve that fits --- if not JB weld should work .

Thanks for the help everyone! I was able to repair it with JB weld and a lathe, I just put a little on the scar and polished it down. Not pretty but hopefully it will hold!

-