You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Biohazard

- Thread starter Teeth & Tires

- Start date

-

The old exhaust system...what a mess! Start with the stock setup: 2 into 1 with a 1 7/8" pipe all the way back to the tail...but somewhere along the line, somebody put in a dual exhaust setup (frowny face) which is where it gets interesting.

The driver's side:

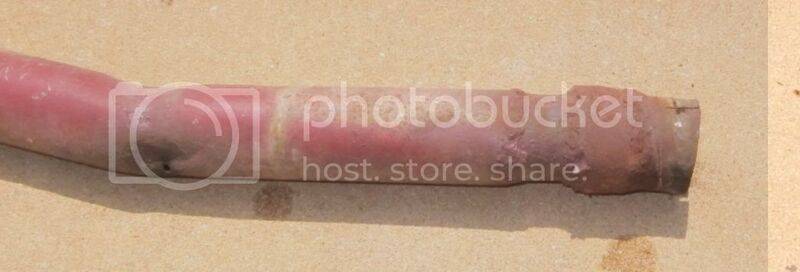

The original Y collector is still there but a cap was clamped over the passenger side inlet. Okay, no big deal. The muffler on that side was replaced with one that had larger inlet/outlet diameters so the installer used 'sleeves' to plus-up the pipe size to fill the muffler inlets. Here is the outlet side of the left muffler..

Further back, the curvy tailpipe had been replaced. Perhaps the original one rusted out? Take a gander at this most excellent weld work...

The passenger side:

Going from rear to front, saving the best for last.

The entire pass. side exhaust was done in 2-inch pipe so, that doesn't even match the driver's side....and they still couldn't marry up a muffler with the correct inlet/outlet diameters! Here's a peak at what it took to stuff the 2 1/2" inlet hole with a 2" pipe:

And at the other end:

And now for the creme de la creme. Must have been a problem sealing up the pipe to the manifold. Nothing a little RTV can't fix!

Keeping things in perspective.

Some of this awesome exhaust work is unforgiveable when done to a 44-year-old rolling museum piece (and so it shall be rectified) but when a car, any car, is your daily driver you sometimes just have to go with the cheapest and easiest fix in order to get your ride back on all fours. Thus, no disrespect is intended when pointing out some of the obvious faults discovered in the exhaust system.

Doing it right.

The car is going back to a single exhaust. I plan to order the pre-formed 2-into-1 collector from Accurate and run 2" pipe into a muffler with 2" fittings to finish the setup.

The driver's side:

The original Y collector is still there but a cap was clamped over the passenger side inlet. Okay, no big deal. The muffler on that side was replaced with one that had larger inlet/outlet diameters so the installer used 'sleeves' to plus-up the pipe size to fill the muffler inlets. Here is the outlet side of the left muffler..

Further back, the curvy tailpipe had been replaced. Perhaps the original one rusted out? Take a gander at this most excellent weld work...

The passenger side:

Going from rear to front, saving the best for last.

The entire pass. side exhaust was done in 2-inch pipe so, that doesn't even match the driver's side....and they still couldn't marry up a muffler with the correct inlet/outlet diameters! Here's a peak at what it took to stuff the 2 1/2" inlet hole with a 2" pipe:

And at the other end:

And now for the creme de la creme. Must have been a problem sealing up the pipe to the manifold. Nothing a little RTV can't fix!

Keeping things in perspective.

Some of this awesome exhaust work is unforgiveable when done to a 44-year-old rolling museum piece (and so it shall be rectified) but when a car, any car, is your daily driver you sometimes just have to go with the cheapest and easiest fix in order to get your ride back on all fours. Thus, no disrespect is intended when pointing out some of the obvious faults discovered in the exhaust system.

Doing it right.

The car is going back to a single exhaust. I plan to order the pre-formed 2-into-1 collector from Accurate and run 2" pipe into a muffler with 2" fittings to finish the setup.

I've actually had a productive week, despite not having posted anything 'till now. More work than posting is good...so I'm catching up today.

Disassembled and cleaned the parking lamps. Sprayed everything with ammonia just so I could safely store them since they won't be used for a while.

Disassembled and cleaned the parking lamps. Sprayed everything with ammonia just so I could safely store them since they won't be used for a while.

Must plug the Marine Clean. It is doing a fabulous job breaking thru the age-old road grime accumulated all over the underside of the car. Rinsing was done with the 2500psi washer. Lots of brown rinse water came off of her and, when checked later in the evening, she smells soooo much better.

Monday:

From the firewall back to the front seats, from edge to edge, with particular focus on the trans tunnel. Also did the front wheel arches (again).

Tuesday:

Front seats back to the body seam just ahead of the rear axle. It was nice having the mufflers out of the way.

Wednesday:

Body seam back to the area over the rear axle, including the axle itself and the rear wheel arches.

Having the mufflers and piping out of the way made underside cleaning alot easier. Consider that I'm having to raise the car with floor jacks and lay on the driveway to do the cleaning - its a pain. These guys, however, really slow things down for me.

Brown Widows. I found 3 residing under the car, so far.

A bit more degreasing to do on the rear axle assembly along with finishing the underbody by continuing back to the very rear of the car.

But not today. :sleepy3:

Monday:

From the firewall back to the front seats, from edge to edge, with particular focus on the trans tunnel. Also did the front wheel arches (again).

Tuesday:

Front seats back to the body seam just ahead of the rear axle. It was nice having the mufflers out of the way.

Wednesday:

Body seam back to the area over the rear axle, including the axle itself and the rear wheel arches.

Having the mufflers and piping out of the way made underside cleaning alot easier. Consider that I'm having to raise the car with floor jacks and lay on the driveway to do the cleaning - its a pain. These guys, however, really slow things down for me.

Brown Widows. I found 3 residing under the car, so far.

A bit more degreasing to do on the rear axle assembly along with finishing the underbody by continuing back to the very rear of the car.

But not today. :sleepy3:

I'll not bore you all with what I did do today, project-wise, because it had nothing to do with the car. I was hoping to start re-assembling the HVAC unit but a couple of bare metal panels which I had dropped off for sandblasting have still not been blasted. My guy is chronic about not getting things done when he says he will so I really need to look for someone else. Hate to ***** but it's every time. I've lost two weekends on this guy.

As for the car...

With nothing really going on, I took our fogger and filled it with a natural biocide dilution and fogged the isht out of the car's interior. I think I'm just going to keep doing this every few days. The car smells great. I had really gotten the rotten mold smell under control quite some time ago but it still has the 40-year-old road gunk smell - but even that is dwindling since I started degreasing the underbelly. Some spots (such as the transmission tunnel) could probably benefit from a second spray but the work is paying off and I couldn't be happier.

I have a pre-cut firewall insulation kit on the way.

As for the car...

With nothing really going on, I took our fogger and filled it with a natural biocide dilution and fogged the isht out of the car's interior. I think I'm just going to keep doing this every few days. The car smells great. I had really gotten the rotten mold smell under control quite some time ago but it still has the 40-year-old road gunk smell - but even that is dwindling since I started degreasing the underbelly. Some spots (such as the transmission tunnel) could probably benefit from a second spray but the work is paying off and I couldn't be happier.

I have a pre-cut firewall insulation kit on the way.

Question:

Is the paint on the dash supposed to be glossy, like the exterior, or is it deliberately flat? Mine's ridiculously flat but I figure that's pobably age and oxidation.

Is the paint on the dash supposed to be glossy, like the exterior, or is it deliberately flat? Mine's ridiculously flat but I figure that's pobably age and oxidation.

My dash frame and column are "Satin Black", imagine yours is similar. The inside on the doors above and below the door panels is gloss black. Exterior of the car was "Dark Forest Green Metallic", carpet, seats, dash pad, door panels were black. Seatbelts were dark green.

Hmmm...okay. I may still go gloss or at least semi gloss.

But on to other things! Lookie what I just found!

The parking lamp is crap but that's clearly not an issue. Stoked. Now if only I could find a driver's side!

But on to other things! Lookie what I just found!

The parking lamp is crap but that's clearly not an issue. Stoked. Now if only I could find a driver's side!

Question:

Is the paint on the dash supposed to be glossy, like the exterior, or is it deliberately flat? Mine's ridiculously flat but I figure that's pobably age and oxidation.

Yes and the correct term is " suede" funish.

DPR and others sell the factory mix in suede, and yes it fades over time.

If you don't find the drivers grill let me know I have one that is salvagable and about in the same shape.

PM sent!

And...last night I ordered my headliner and roof insulation.

And...last night I ordered my headliner and roof insulation.

THEWHITEZOMBIE

Mopars an Heavy Metal

Looking great man. Keep it up

Dan,

Correction

TCP Global for the suede dash and steering column paint....

"Assume" Regatta Red

Paint Code 71688

Correction

TCP Global for the suede dash and steering column paint....

"Assume" Regatta Red

Paint Code 71688

67 prostreet gt

Well-Known Member

Yes and the correct term is " suede" funish.

DPR and others sell the factory mix in suede, and yes it fades over time.

If you don't find the drivers grill let me know I have one that is salvagable and about in the same shape.

Dang iPhone .....

No gloss satin Suede...

Monday afternoon, I re-drenched the trans tunnel with degreaser to see if the runoff was clear or grungie. Happy to say, 90% clear - meaning the degreaser had cut thru the crud very effectively.

The K-frame was still well-coated with gunk on the underside so I went after it with the degreaser and a scrubby pad and labored for about 45 minutes. Very persistent crud and, I can tell you, I did not get it all off but what's significant about this is that the sludge I removed took with it nearly all of the remaining stink. I say 'nearly' because I basically quit before I was done - knowing there was still more crap to clean up - and if I crawl under the car and plant my nose up against every structural component like an obsessed schizophrenic, I can certainly find some residual funk. But I have to look for it now..it doesn't hang in the air all around the car like before.

This fish has been cleaned.

The K-frame was still well-coated with gunk on the underside so I went after it with the degreaser and a scrubby pad and labored for about 45 minutes. Very persistent crud and, I can tell you, I did not get it all off but what's significant about this is that the sludge I removed took with it nearly all of the remaining stink. I say 'nearly' because I basically quit before I was done - knowing there was still more crap to clean up - and if I crawl under the car and plant my nose up against every structural component like an obsessed schizophrenic, I can certainly find some residual funk. But I have to look for it now..it doesn't hang in the air all around the car like before.

This fish has been cleaned.

First order of business:

Received the new grille today and I'm very pleased. It is exactly as you would have expected from the pic above in that there is the one crack in the surround (easily fixable) and some very light bubbling in the chrome. No big deal there. The park lamp is actually in very nice condition aside from the crazing in the lens.

Labor update:

Finally got my A/C plates back from sandblasting and got right to putting the HVAC box together. I'm using the DMT kit. Nice stuff but I opted out of using globs of caulk to seal the little gaps and instead applied little bits of roof flashing. I had a roll of it and it is very sticky.

So I started with that vent flap - the one that's a real pill to get out.

Cleaned it up.

...and here's the finished product.

Here's the HVAC box all plugged up

Closer...

All the insulation panels glued in place.

The inner panel.

Tested the evaporator - it seems to be air-tight.

Marinated the drip pan in ammonia for 48+ hours, buffed it down with steel wool, then I soaked it in a chemical rust converter. Being a double-wall pan makes it tough to reliably clean but my nose tells me its not impossible. Think I'm gonna paint it, too. If I do, that'll slow the reassembly but...no rush.

Received the new grille today and I'm very pleased. It is exactly as you would have expected from the pic above in that there is the one crack in the surround (easily fixable) and some very light bubbling in the chrome. No big deal there. The park lamp is actually in very nice condition aside from the crazing in the lens.

Labor update:

Finally got my A/C plates back from sandblasting and got right to putting the HVAC box together. I'm using the DMT kit. Nice stuff but I opted out of using globs of caulk to seal the little gaps and instead applied little bits of roof flashing. I had a roll of it and it is very sticky.

So I started with that vent flap - the one that's a real pill to get out.

Cleaned it up.

...and here's the finished product.

Here's the HVAC box all plugged up

Closer...

All the insulation panels glued in place.

The inner panel.

Tested the evaporator - it seems to be air-tight.

Marinated the drip pan in ammonia for 48+ hours, buffed it down with steel wool, then I soaked it in a chemical rust converter. Being a double-wall pan makes it tough to reliably clean but my nose tells me its not impossible. Think I'm gonna paint it, too. If I do, that'll slow the reassembly but...no rush.

Didn't realize I was missing this piece until I saw it on eBay. Again, I'm no transmission expert but I thought it was odd being able to see gear teeth from under the car.

Then I saw this and thought, "Ah ha!"

Then I saw this and thought, "Ah ha!"

Continuing the hvac reassembly.

I used "The Right Stuff" rust converter on the drip pan. I poured some into it and slushed it around to treat the inner sides of the drip pan that you just can not get to any other way. I then steel-wooled the outer surface, treated it with rust converter and sprayed it with rustoleum. After letting it sit for 30 minutes or so, I moved it to the grill and baked it for 45 minutes at 250F. Once it cooled, it was completely cured and I was able to continue with putting it all together.

Butyl caulk holding the protective screen down and the rope caulk in place before securing the other metal plate.

The 3" strip you see in the upper left corner should not have been there. I did end up removing it.

I put the folded metal panel on and installed the new seal around where the evap tubes exit the box. After that, I found 50 other things to do. Fortunately, one of those things was concluding with the underside degreasing (from the rear axle back) though I would like to spend a little more time on the rear end. In the interior, I sprayed the wire bundles and firewall with Marine Clean. (why not, the stuff does such a great job cleaning things) and, as I type this, there is one of those ozone generators running at max output inside the cabin with it all closed up. I just figure I may as well throw everything I have at it while it is still all disassembled.

I used "The Right Stuff" rust converter on the drip pan. I poured some into it and slushed it around to treat the inner sides of the drip pan that you just can not get to any other way. I then steel-wooled the outer surface, treated it with rust converter and sprayed it with rustoleum. After letting it sit for 30 minutes or so, I moved it to the grill and baked it for 45 minutes at 250F. Once it cooled, it was completely cured and I was able to continue with putting it all together.

Butyl caulk holding the protective screen down and the rope caulk in place before securing the other metal plate.

The 3" strip you see in the upper left corner should not have been there. I did end up removing it.

I put the folded metal panel on and installed the new seal around where the evap tubes exit the box. After that, I found 50 other things to do. Fortunately, one of those things was concluding with the underside degreasing (from the rear axle back) though I would like to spend a little more time on the rear end. In the interior, I sprayed the wire bundles and firewall with Marine Clean. (why not, the stuff does such a great job cleaning things) and, as I type this, there is one of those ozone generators running at max output inside the cabin with it all closed up. I just figure I may as well throw everything I have at it while it is still all disassembled.

I actually have been working on this thing. Here's some proof...

Okay so it was time to get the blower and blower motor back into the housing but, naturally, it was more involved than just screwing the darn thing into place.

The round mounting trim that houses the motor had gotten a fair amount of overspray from when the car got its most recent coat of R6 so the two metal parts got fine sanded and then sprayed with Rustoleum Engine black. I baked the pieces like I did the drip pan.

The rubber seal was old and dirty so I blew the dust off of a product I brought back from Germany called "Gummi Pflege" which translates to rubber care. This stuff restores the flex and oily-ness to rubber parts and thats exactly what it did for the seal. Even the filth on the seal practically fell off as I rubbed the stuff into it.

I used a scrubby pad to buff the overspray off the rubber motor isolators.

The motor is supposed to be black...got it...but I chose to just steel wool mine and make it shine.

Okay so it was time to get the blower and blower motor back into the housing but, naturally, it was more involved than just screwing the darn thing into place.

The round mounting trim that houses the motor had gotten a fair amount of overspray from when the car got its most recent coat of R6 so the two metal parts got fine sanded and then sprayed with Rustoleum Engine black. I baked the pieces like I did the drip pan.

The rubber seal was old and dirty so I blew the dust off of a product I brought back from Germany called "Gummi Pflege" which translates to rubber care. This stuff restores the flex and oily-ness to rubber parts and thats exactly what it did for the seal. Even the filth on the seal practically fell off as I rubbed the stuff into it.

I used a scrubby pad to buff the overspray off the rubber motor isolators.

The motor is supposed to be black...got it...but I chose to just steel wool mine and make it shine.

Before installing the blower motor, I decided to put 12 volts to it again and listen to it run. Seemed to have a slight squeak but otherwise, no issues. Still, on a whim, I split the motor body and pulled the rotor just to lube the end of the shaft. After wrestling it back together, test-drive results were: no squeak and, the longer I kept power to it, the faster it ran.

Couple of things you may notice: The plate at the evaporator ports got painted black on the cabin side (you can see the paint on the edges). I also painted one of the vacuum diaphragm mounts. You can't see this stuff once installed - it was really just for rust control. I also cut thin strips of roof flashing to seal up the box halves around the blower. I used it only on the firewall side so it won't be noticed from the cabin.

Couple of things you may notice: The plate at the evaporator ports got painted black on the cabin side (you can see the paint on the edges). I also painted one of the vacuum diaphragm mounts. You can't see this stuff once installed - it was really just for rust control. I also cut thin strips of roof flashing to seal up the box halves around the blower. I used it only on the firewall side so it won't be noticed from the cabin.

Cooling tube for the blower fan installed.

Began putting the heater side of the box together. Like the A/C evaporator, I sprayed the heater core with POR-15's Metal Prep which really cleaned off the fins. Took a little steel wool to the copper tubes and the mounting flange around the core. Below, you can see the rope caulk in place prior to fitting the core into the box as well as a few places where i brushed some black paint over rivet heads to keep them from rusting out.

Below is the core installed in the box half. Very clean - it will yield gobs of soothing warmth!

I have a few flap doors needing either cleaned or painted and then to have the grey foam panels glued to them. Otherwise, just a few hinges and rods needing steel-wooled and oiled before the boxes can be closed up.

Below is the core installed in the box half. Very clean - it will yield gobs of soothing warmth!

I have a few flap doors needing either cleaned or painted and then to have the grey foam panels glued to them. Otherwise, just a few hinges and rods needing steel-wooled and oiled before the boxes can be closed up.

More work on the A/C and heater boxes. Shot this of the heater side before pulling the actuators off so I would have a reference for reassembly.

You can see some light surface rust on the actuator rods which will be steel wooled off. The unpainted actuator looks dull with light oxidation and the steel brackets all have a small amount of rust. I plan to polish the actuator and brush paint the brackets in the interest of preservation.

In the next shot, if you look inside the box behind the open door, you can see a rusty rod upon which a flap door pivots. The door that attaches to it is also rusty as hell.

Here, now, is the flap door and the 2 fasteners that hold it against the pivot rod...

I treated the door with rust converter, rinsed, then sprayed it with Metal Prep, rinsed, dried, then painted it. Ditto the fasteners. The pivot rod just got worked clean with steel wool. Here is the product after painting.

Here is an unpainted actuator after cleaning up. It really only took a light buffing with steel wool to make it look gorgeous.

There is one actuator that must be visible from the cabin and so is painted flat black. Mine had a few scratches so a shot of paint for it was in order. I chose satin black for just a hint of shine.

An actuator returned to its bracket. Note the rust-free linkage rods behind it.

I think I'm going to brush-paint all the rusty brackets at once after the boxes are reassembled. Tomorrow, I will wipe down the flap doors and glue on the open-cell foam panels from the kit. The bare metal parts will get wiped down with oil and the whole hvac assembly should become one, once again.

You can see some light surface rust on the actuator rods which will be steel wooled off. The unpainted actuator looks dull with light oxidation and the steel brackets all have a small amount of rust. I plan to polish the actuator and brush paint the brackets in the interest of preservation.

In the next shot, if you look inside the box behind the open door, you can see a rusty rod upon which a flap door pivots. The door that attaches to it is also rusty as hell.

Here, now, is the flap door and the 2 fasteners that hold it against the pivot rod...

I treated the door with rust converter, rinsed, then sprayed it with Metal Prep, rinsed, dried, then painted it. Ditto the fasteners. The pivot rod just got worked clean with steel wool. Here is the product after painting.

Here is an unpainted actuator after cleaning up. It really only took a light buffing with steel wool to make it look gorgeous.

There is one actuator that must be visible from the cabin and so is painted flat black. Mine had a few scratches so a shot of paint for it was in order. I chose satin black for just a hint of shine.

An actuator returned to its bracket. Note the rust-free linkage rods behind it.

I think I'm going to brush-paint all the rusty brackets at once after the boxes are reassembled. Tomorrow, I will wipe down the flap doors and glue on the open-cell foam panels from the kit. The bare metal parts will get wiped down with oil and the whole hvac assembly should become one, once again.

This long hiatus should be labelled, 'daughter's wedding intermission'.

But I'm back at it again.

-Finished placing and gluing all the HVAC foams and seals.

-Painted all the bare metal brackets on the exterior of the box.

-Have the entire HVAC just about reassembled except for one piece I can't find ( arrrgggghhhh )

-Ordered some Chrysler R6 to touch up the engine compartment before putting the HVAC back in.

So the short target is: paint the firewall, hang the HVAC system, then paint and install the dash frame. That last item means sorting, wrapping, and reconnecting alot of the wiring harness so, it will likely take a while.

But I'm back at it again.

-Finished placing and gluing all the HVAC foams and seals.

-Painted all the bare metal brackets on the exterior of the box.

-Have the entire HVAC just about reassembled except for one piece I can't find ( arrrgggghhhh )

-Ordered some Chrysler R6 to touch up the engine compartment before putting the HVAC back in.

So the short target is: paint the firewall, hang the HVAC system, then paint and install the dash frame. That last item means sorting, wrapping, and reconnecting alot of the wiring harness so, it will likely take a while.

So I lost hours....literally hours hunting for a couple of small parts that I managed to misplace. Found them today and that would be today's most significant achievement. Here are the offending little turds:

Meanwhile, here are a couple shots of the A/C box, mostly assembled.

Meanwhile, here are a couple shots of the A/C box, mostly assembled.

-