j par

Well-hung Member

So I got a crap load of electronic stuff from Speedmaster with their sale. All of which hoping beyond hopes not too good to be true LOL..

Anyways if two out of the five of these things work I'll still be ahead...

More to the point the distributor is already questionable...

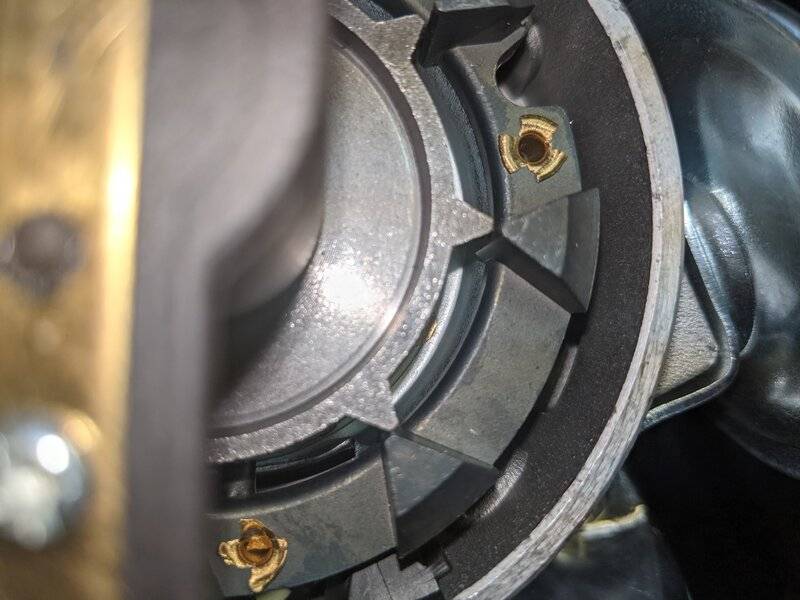

I turn it and it sticks just a tad bit at one point. I can see the eight little contacts that are probably supposed to be slightly gapped and at some point it comes around and one of them touches..

Question being will this make it not work? Or will this work itself out after a few thousand revolutions..?

Thank you for everyone's experience and knowledge..

And as you all know there's no customer service for Speedmaster so it's either make it work or just toss it and try something else....

This has the built-in ignition module...

Anyways if two out of the five of these things work I'll still be ahead...

More to the point the distributor is already questionable...

I turn it and it sticks just a tad bit at one point. I can see the eight little contacts that are probably supposed to be slightly gapped and at some point it comes around and one of them touches..

Question being will this make it not work? Or will this work itself out after a few thousand revolutions..?

Thank you for everyone's experience and knowledge..

And as you all know there's no customer service for Speedmaster so it's either make it work or just toss it and try something else....

This has the built-in ignition module...