You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Eddy valve spring bushings?

- Thread starter Valkman

- Start date

-

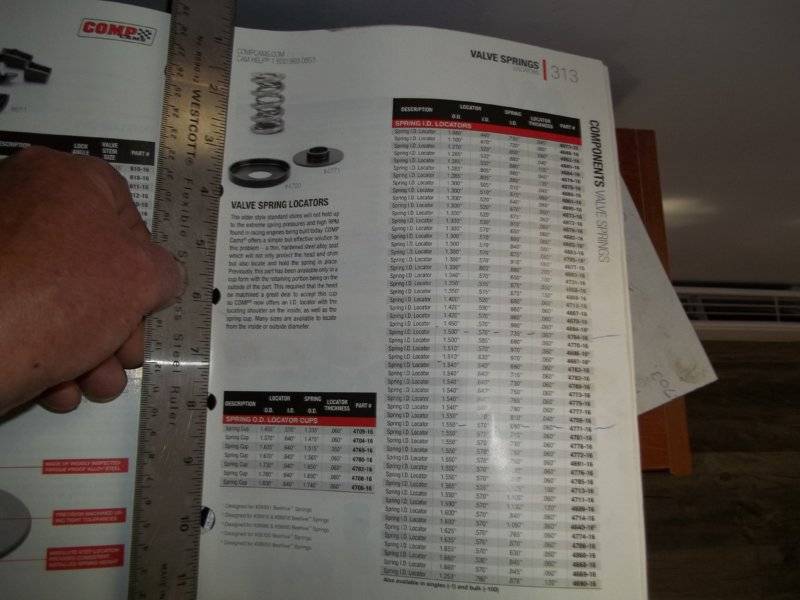

Good question, thanks for asking, as I would also like to know that. I will wait for the answer!Does anyone know the orientation of these bushings between the valve spring and the head? Just checking myself and want to be sure.View attachment 1715192693

Is this what you found under every spring combo?

I posted that they are shims for installed height (which some are) and then saw that you were talking about Edelbrock Aluminum.Is this what you found under every spring combo?

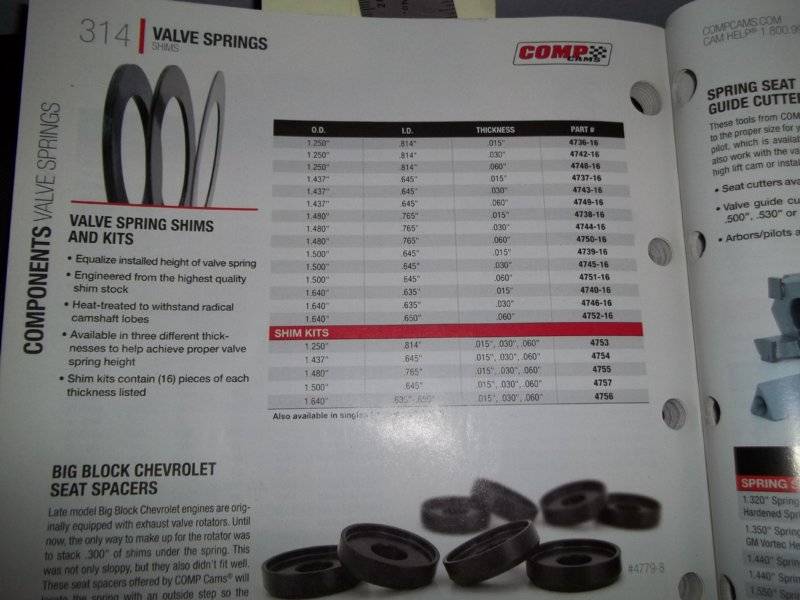

These shims (sorry I shouldn't have called them bushings) were installed on the heads before I took them apart to do an inspection and port the heads. The black shim is hardened and others are made of different materials so just want make I put them back in the right order.

Those are valve spring shims used to adjust spring height. With aggressive springs you should look into spring cups to protect the head (keep the spring from digging into the aluminum) and locate the spring (keeping it centered).

Gold colored is .060 silver is .030 and black is .015. Use the thickest nearest to the spring, because it will have a tendency to chew up the thinner shims, there are hardened spring pads available from Comp Cams (or others) that could do a better job than just a stack of these things.

AJ/FormS

68 Formua-S fastback clone 367/A833/GVod/3.55s

- Joined

- Jan 19, 2014

- Messages

- 24,946

- Reaction score

- 12,297

I put the hardened ones under the springs.

In my experience, which ain't much; the Eddie springs,at the stock installed heights

won't take a fast-rate lobe,at or near their max lift spec, with 1.6 arms, cheap lifters, and a 7000 shift-rpm ....... That's a mouthfull, lol.

In my experience, which ain't much; the Eddie springs,at the stock installed heights

won't take a fast-rate lobe,at or near their max lift spec, with 1.6 arms, cheap lifters, and a 7000 shift-rpm ....... That's a mouthfull, lol.

Last edited:

Do you mean between the shims and the spring?I put the hardened ones under the springs

AJ/FormS

68 Formua-S fastback clone 367/A833/GVod/3.55s

- Joined

- Jan 19, 2014

- Messages

- 24,946

- Reaction score

- 12,297

Hyup. It prevents the others below it from getting smooshed when the valves float,lol.

It is better to put the hardened ones next to the heads, to protect them, but a little valve float will hammer the others into thin cross-section saucers, and then they lose seat pressure, and then they float even sooner. To prevent pump-up I run adjustable arms and correct-length push-rods and 1/2 turn preload. I used to run 1/4 turn but I had to keep adjusting different valves all summer, as the shims kept getting banged out. At 1/2 turn on better springs,she has gone many summers now.

I don't need to shift at 7000, I just love the sound of the 360 screaming thru dual 3" cannons for 5 to 7 seconds atta time.It's kindof addictive, as you might imagine..

It is better to put the hardened ones next to the heads, to protect them, but a little valve float will hammer the others into thin cross-section saucers, and then they lose seat pressure, and then they float even sooner. To prevent pump-up I run adjustable arms and correct-length push-rods and 1/2 turn preload. I used to run 1/4 turn but I had to keep adjusting different valves all summer, as the shims kept getting banged out. At 1/2 turn on better springs,she has gone many summers now.

I don't need to shift at 7000, I just love the sound of the 360 screaming thru dual 3" cannons for 5 to 7 seconds atta time.It's kindof addictive, as you might imagine..

nm9stheham

Well-Known Member

FWIW, I looked at the info with the SBM Edelbrock heads and looked at their online info, and found conflicting info for the need for the spring cups. So I called Edelbrock about the need for spring cups, and after some back and forth, I was told that they weren't needed with the SBM Performer AL heads.

So take that as you will, but I bet with some more aggressive, higher lift cams, they would become almost necessary.

AND FWIW #2, I suspect the thin shims are made from a harder material simply because they have to be in order to not tear up under the spring contact pressure. With that logic, it seems wiser to put them at the bottom of the stack.

So take that as you will, but I bet with some more aggressive, higher lift cams, they would become almost necessary.

AND FWIW #2, I suspect the thin shims are made from a harder material simply because they have to be in order to not tear up under the spring contact pressure. With that logic, it seems wiser to put them at the bottom of the stack.

Addiction.... .I think we are closing in on the problem here LOLI don't need to shift at 7000, I just love the sound of the 360 screaming thru dual 3" cannons for 5 to 7 seconds atta time.It's kindof addictive, as you might imagine..

AJ/FormS

68 Formua-S fastback clone 367/A833/GVod/3.55s

- Joined

- Jan 19, 2014

- Messages

- 24,946

- Reaction score

- 12,297

My engine ain't all that, but she's sure willing. And the combo is dynomite.

If I could, I'd like to take every one of you for a spin, one by one of course.

I'm gonna dump the clutch at 3500, wind her up to 7000, and keep the tach there to 80/90 mph. You will not see the needle drop, nor hear the engine bog down, nor be able to lean forward. The car will go where ever I point it. The rear will not step out on it's own. It will be like being shot out of a cannon, a torpedo tube, faster than a rocket launcher.

And those screaming dual 3s will not disappoint.

Down at the end I'm gonna hit the brakes, just because, and in a 68 there is no shoulder belt, so your chest will slam your head forward and it will come dangerously close to the thin dashpad. If you had hands on the pad, your arms will crumple under the strain.

Then I'm gonna do a couple of victory figure eights down there, sending your body flailing from side to side and your helmet will hit the side window glass .

Then I'm gonna take you on a 200ft, 360 degree, near full-lock, second or second and a half gear, power slide, again with the pipes screaming. It's gonna be CCW so I don't have to deal with you being in my lap. Maybe we'll go 'round twice.When we come out of it;

I'm gonna dance the rear end left and right a few times,and you better still be wearing a helmet, cuz you won't be able to control where your head is gonna be for the next couple of seconds.

After that I'm gonna make it up as I go; some lefts, some rights, some sudden brake applications, and a lotta slides. A lotta slides.

When we get back to base, you will either have have the silliest looking grin on your face,be giggling like a schoolgirl, and for many seconds you will forget you are wearing the stoopid yellow snowmobile helmet, OR, I will have to tug you outta the front seat and help you sit down, OR, you will be shampooing my passenger seat for the next guy, AND, you are likely to be a little sore the next day. We can do that time after time, all afternoon. Few of you will want a second go-round. But you are gonna have one heck of a memory.

But I digress,lol.

If I could, I'd like to take every one of you for a spin, one by one of course.

I'm gonna dump the clutch at 3500, wind her up to 7000, and keep the tach there to 80/90 mph. You will not see the needle drop, nor hear the engine bog down, nor be able to lean forward. The car will go where ever I point it. The rear will not step out on it's own. It will be like being shot out of a cannon, a torpedo tube, faster than a rocket launcher.

And those screaming dual 3s will not disappoint.

Down at the end I'm gonna hit the brakes, just because, and in a 68 there is no shoulder belt, so your chest will slam your head forward and it will come dangerously close to the thin dashpad. If you had hands on the pad, your arms will crumple under the strain.

Then I'm gonna do a couple of victory figure eights down there, sending your body flailing from side to side and your helmet will hit the side window glass .

Then I'm gonna take you on a 200ft, 360 degree, near full-lock, second or second and a half gear, power slide, again with the pipes screaming. It's gonna be CCW so I don't have to deal with you being in my lap. Maybe we'll go 'round twice.When we come out of it;

I'm gonna dance the rear end left and right a few times,and you better still be wearing a helmet, cuz you won't be able to control where your head is gonna be for the next couple of seconds.

After that I'm gonna make it up as I go; some lefts, some rights, some sudden brake applications, and a lotta slides. A lotta slides.

When we get back to base, you will either have have the silliest looking grin on your face,be giggling like a schoolgirl, and for many seconds you will forget you are wearing the stoopid yellow snowmobile helmet, OR, I will have to tug you outta the front seat and help you sit down, OR, you will be shampooing my passenger seat for the next guy, AND, you are likely to be a little sore the next day. We can do that time after time, all afternoon. Few of you will want a second go-round. But you are gonna have one heck of a memory.

But I digress,lol.

Last edited:

TheTieWrapKid

Well-Known Member

Me first. Bang some gears!

yellow rose

Overnight Sensation

I put the hardened shim under the spring.

They really should all be hardened shims for any performance application.

I detest those shims with the grooves in them. Never put the grooves against the head. The grooves will eat away the head.

They really should all be hardened shims for any performance application.

I detest those shims with the grooves in them. Never put the grooves against the head. The grooves will eat away the head.

AJ/FormS

68 Formua-S fastback clone 367/A833/GVod/3.55s

- Joined

- Jan 19, 2014

- Messages

- 24,946

- Reaction score

- 12,297

On that, you might be a lil disappointed, as the most you will see is one stickshift, at 66 mph, and two electrics, at 50 and 83 as we put the GVOD thru it's routine. Top of second-over, with 3.55s, is 106@7000. Top of third is 113@7000. She cruses 65=2240. and,She hits 93 in the 1/8 at 6150 in second-over.Me first. Bang some gears!

Just for you tho, I can downshift 2-1 at a crappy too-low rpm and skid the back end for a ways, that's always exciting.

I'm not big on J-hooks, but sometimes I wipe out and then if I find myself declutched and rolling backwards, well I have been known to do sillier things.

Like What? Well sitting in one place with the wheels cranked hard over and smoking the tires in second as we slowly idle around in circles getting dizzy, that's sometimes a hit, altho neither of my daughters wants a re-take. That's kindof too bad cuz it was soooo hilarious the first times,lol.There was tire smoke everywhere, and to tell the truth, I couldn't see anything anymore. When the smoke cleared, there we were, exactly where I was expecting to be,lol, in the middle of a big black stinky circle; the good kind of stinky.

Last edited:

good advise, I am one not to let off the of the gas pedal!. It prevents the others below it from getting smooshed when the valves float,l

The shims on these heads originally were installed from the head up: harden (black) med. shim (silver) lg.(copper). The shims are stamped " THIS SIDE UP" on the smooth side. I was thinking it might be better to have the harden shim against the spring instead. Thanks AJ/FormS.

I'm not using a wild cam I don't think I'll need cups

AJ/FormS

68 Formua-S fastback clone 367/A833/GVod/3.55s

- Joined

- Jan 19, 2014

- Messages

- 24,946

- Reaction score

- 12,297

It is not really about a wild cam, it is about rate of lift and keeping the valve train together, as the lifter flies over the nose of the cam. It's true that low-lift short-period cams are usually easier to control., but those factory Eddie springs won't have a lot of over-the-nose pressure with a low-lift cam,lol. So..... you might have to check with he manufacturer to see how they will handle your particular cam.

Some guys run a lot of lifter preload, and so if they pump up, the valve opens a lot further than expected, and there is always a chance that if you don't do your homework, the piston and the valve will try to occupy the same place at the same time, with usually disastrous, or catastrophic, results.

My question is; if you go to the expense of getting Eddies...........what non wild-cam are you using.

FWI; I did successfully run the Eddie springs with the 292/108 cam,for a short time; so there's that,lol.

Also FWI: the Hughes 111Xs( I think 1110) have been on my Eddies since 2000, and have seen two cams; a 223 and a [email protected], both with adjustable 1.6 arms,and new Hughes HD lifters each time. So there's that then too,lol.

Some guys run a lot of lifter preload, and so if they pump up, the valve opens a lot further than expected, and there is always a chance that if you don't do your homework, the piston and the valve will try to occupy the same place at the same time, with usually disastrous, or catastrophic, results.

My question is; if you go to the expense of getting Eddies...........what non wild-cam are you using.

FWI; I did successfully run the Eddie springs with the 292/108 cam,for a short time; so there's that,lol.

Also FWI: the Hughes 111Xs( I think 1110) have been on my Eddies since 2000, and have seen two cams; a 223 and a [email protected], both with adjustable 1.6 arms,and new Hughes HD lifters each time. So there's that then too,lol.

AJ/FormS

68 Formua-S fastback clone 367/A833/GVod/3.55s

- Joined

- Jan 19, 2014

- Messages

- 24,946

- Reaction score

- 12,297

good advise, I am one not to let off the of the gas pedal!

The shims on these heads originally were installed from the head up: harden (black) med. shim (silver) lg.(copper). The shims are stamped " THIS SIDE UP" on the smooth side. I was thinking it might be better to have the harden shim against the spring instead. Thanks AJ/FormS.

I'm not using a wild cam I don't think I'll need cups

If you do it that way remember YRs advise, which I agree with, not to mount the serrated aluminum-cutting side against the head.

Use something like this instead, and have it that something thick is against the spring. those supplied ones are crap, only meant for stock touch-ups and that thin one WILL chew to **** first in line next to the spring. No pictures to prove it cause we just throw them out when they come in all chewed to ****.

nm9stheham

Well-Known Member

The Edlebrock springs that come standard on the Performer heads have a rate of 327 lb/in as opposed to 345 lb/in for the Hughes 1110's. So not too surprising that they both worked fine for you.... there's only a 5% spring difference.My question is; if you go to the expense of getting Eddies...........what non wild-cam are you using.

FWI; I did successfully run the Eddie springs with the 292/108 cam,for a short time; so there's that,lol.

Also FWI: the Hughes 111Xs( I think 1110) have been on my Eddies since 2000, and have seen two cams; a 223 and a [email protected], both with adjustable 1.6 arms,and new Hughes HD lifters each time. So there's that then too,lol.

Guys guys, I think we're over thinking this. I'm not building a 600 hp monster that needs to rev to 8k. I'm building a fun street engine that might see 400 hp if I'm lucky. "Speed cost money how fast do you want to go" , I don’t have that much money and I don't need to go that fast. I just wanted to know the best way to install these shims.

Wyrmrider

Well-Known Member

aj I put shoulder belts in My 68 both front and rear

the supports with proper thread are there already

I have bench seat so I put in center seat belts also found dark green ones to match from a 1 or 2 year later Newport

they are the ones with the detachable shoulder belt that goes on the stud on the seat belt buckel

Pain in the *** but that's what worked

the supports with proper thread are there already

I have bench seat so I put in center seat belts also found dark green ones to match from a 1 or 2 year later Newport

they are the ones with the detachable shoulder belt that goes on the stud on the seat belt buckel

Pain in the *** but that's what worked

AJ/FormS

68 Formua-S fastback clone 367/A833/GVod/3.55s

- Joined

- Jan 19, 2014

- Messages

- 24,946

- Reaction score

- 12,297

Yeah I saw those anchors when I replaced the headliner, and I even have the black belts.......now in a box.....in the rafters,lol. Another thing I don't have is a 70 pound, slow-me-down, fold-down rear seat; it too is in the rafters. Along with the jack, the spare tire,steel wheels, the CI trans case and tail, the heavy factory OEM buckets, and a few other things. On race day, the one time I went, I got that fat Barracuda down to 3467 pounds,me in it at 220 with helmet(lol), by dropping the quick-disconnect exhaust, and leaving the heater at home, with the belly pan/oilpan protector. ( I got tired of fixing the speed-bump carnage,lol.). I did put the bellypan and exhaust back on.And later in the season, the heater went back in too.aj I put shoulder belts in My 68 both front and rear

the supports with proper thread are there already

I have bench seat so I put in center seat belts also found dark green ones to match from a 1 or 2 year later Newport

they are the ones with the detachable shoulder belt that goes on the stud on the seat belt buckel

Pain in the *** but that's what worked

I bought some real nice Corbeau seats, but by the time they were mounted on sliding tracks and set into place, they looked,IMO, HUGE, way out of scale with the car. My head was nearly into the headliner, and I'm under 5-9. And man were they heavy.

So out they came, and back they went. Along with the 5-point harnesses.

-