Having a real hard time getting a Super Victor 2815 to fit on a set of Edelbrock heads. Finally clearance enough to get the valve covers on ,with doubled up gaskets....but can't get the bolts in on the #3 and #6 intake holes in the head. Trying studs on those 2 but was considering putting a slot on 1 side so I can have stud on each side. Any guidance would be appreciated.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Edelbrock fit issues

- Thread starter 66Valiant528

- Start date

-

Having a real hard time getting a Super Victor 2815 to fit on a set of Edelbrock heads. Finally clearance enough to get the valve covers on ,with doubled up gaskets....but can't get the bolts in on the #3 and #6 intake holes in the head. Trying studs on those 2 but was considering putting a slot on 1 side so I can have stud on each side. Any guidance would be appreciated.

View attachment 1716223812

With it sitting in place how do the ports like up. I take it you test fitted this with the gasket in place and just placed the intake on dry. If so that was a very smart move. On my Victor340 intake my center four holes are a son of a gun. I hold a washer in place and have to use a 1 1/4 (12 point) bolt. Even then I’m only catching a few thread and next tear down I’ll be putting in new helicoils as I’ve used this set of head since 2009 or so. I will be slightly opening up the center four holes so hopefully I can at least use a long bolt but a 12 point does help. Good luck

69FBCuda

Stand back 10' for your viewing pleasure & Safety

Did you remove the china wall pins front and rear? Get the bolts started that you can and tighten them down(not torqued) the rest should follow. Did you fit the gaskets to the intake also?

The ports line up well but the runners are encroaching to the point that you can't get the bolt in. We slotted those 2 holes and are now grinding away at the runner. We have 12 point bolts.

Joy that sharpie to show us where to grind.

Pins are long gone. And I think the grinding has given us the room we need. We shortened those 2 bolts. Nope needs more massaging.

Some guys will never experience this because it’s more common on the Performance type of intakes. The others may be slightly tight but the Super Victor and Victor340 can really test your abilities.

65TerrorCuda

Well-Known Member

Cal Tonsley

Well-Known Member

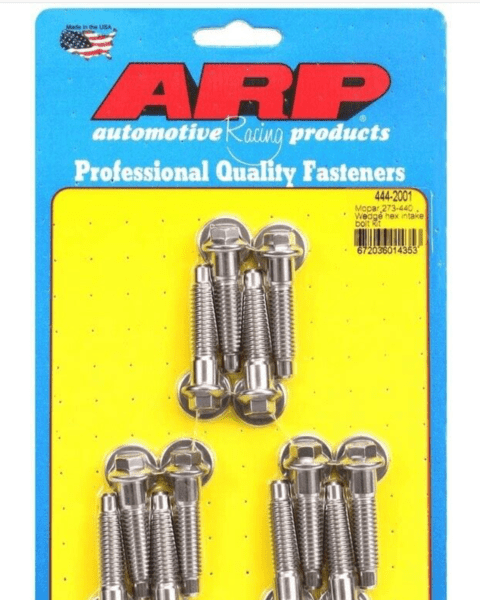

I like to use these small 6pt hex ARP bolts (444-2001) on mine as it means you can get an open ended wrench on when things are getting tight next to the runners. I also shorten up the threads of the bolts for #3 & #6 runners to allow them to just slip past the runners and get started on the threads.

It's all good. Thank you all. The FI bosses on the end of the runner protrude so far over the valve cover flange. That was problem 1. Scribed the bottom of the overhang and saw we had plenty of room to grind. Spacers were ordered ,not sure on the eta. But I could see that was just the beginning of fitting the intake to the Edelbrock heads. Those 2 bolts had to be shortened a little. Oblonging the hole helped. We contemplated 2 studs and a slot on the intake but I really didn't want to do that. There was a lot of meat above the bolt so we kept grinding and test fitting. Success! Sorry I don't have an install picture. I'll get one next time I'm at the shop.

I was really surprised how difficult it was to fit the Edelbrock parts together. I've had valve cover/intake issues before but this job was particularly difficult. There's no reason that this intake can't fit better out of the box. Disappointing.

I was really surprised how difficult it was to fit the Edelbrock parts together. I've had valve cover/intake issues before but this job was particularly difficult. There's no reason that this intake can't fit better out of the box. Disappointing.

It's all good. Thank you all. The FI bosses on the end of the runner protrude so far over the valve cover flange. That was problem 1. Scribed the bottom of the overhang and saw we had plenty of room to grind. Spacers were ordered ,not sure on the eta. But I could see that was just the beginning of fitting the intake to the Edelbrock heads. Those 2 bolts had to be shortened a little. Oblonging the hole helped. We contemplated 2 studs and a slot on the intake but I really didn't want to do that. There was a lot of meat above the bolt so we kept grinding and test fitting. Success! Sorry I don't have an install picture. I'll get one next time I'm at the shop.

I was really surprised how difficult it was to fit the Edelbrock parts together. I've had valve cover/intake issues before but this job was particularly difficult. There's no reason that this intake can't fit better out of the box. Disappointing.

I tried my hardest to explain the reasoning above. Higher bigger ports flow more air but create other issues. We as hot rodders can overcome these issues for better performance. I’ve told guys for years on here about using spacers. For some of us it’s all a part of the job. Don’t expect those spacers to be a bolt on application because again some modifications may be necessary. A search on this site will show you some of the things I’ve ran into with them.

Yes and I admit when I posted this I was hoping you would reply. I know you have had these exact issues in the past and was hoping you could spread some light on the issue. I realize this is a race intake and the owner is going to race the car but I was really surprised what a pita it was to install. Ya I've had to clearance intakes and valve covers before and had intake bolt length/height issues before but this was particularly challenging. Not what I expected from Edelbrock.I tried my hardest to explain the reasoning above. Higher bigger ports flow more air but create other issues. We as hot rodders can overcome these issues for better performance. I’ve told guys for years on here about using spacers. For some of us it’s all a part of the job. Don’t expect those spacers to be a bolt on application because again some modifications may be necessary. A search on this site will show you some of the things I’ve ran into with them.

Newbomb Turk

Well-Known Member

First off, I love that pushrod length. Looks about perfect.

Second...what spacers are you guys talking about and why two gaskets?? Just curious.

Second...what spacers are you guys talking about and why two gaskets?? Just curious.

Yes and I admit when I posted this I was hoping you would reply. I know you have had these exact issues in the past and was hoping you could spread some light on the issue. I realize this is a race intake and the owner is going to race the car but I was really surprised what a pita it was to install. Ya I've had to clearance intakes and valve covers before and had intake bolt length/height issues before but this was particularly challenging. Not what I expected from Edelbrock.

It could be worse or let’s say it could be worse for the head porter. TrickFlow addressed this issue by slotting each hole vertically 1/4 inch. I immediately thought ohhhh man that’s a great idea until I looked and saw they slotted every dog gone hole. When a head porter get an intake the only way we can go about gasket matching it is to use a trusted gasket and match up the holes. Well when Boosted sent me his intake from Washington state to Pa to flow test and the flow numbers weren’t where we wanted then it turned into a porting job. Great until I tried to line up an intake gasket. Do I line the gasket with the top of the hole, the middle, or the bottom??? I didn’t want to risk removing metal in the wrong direction so I ended up not porting it. Now I’ll never know because I won’t take on that job and I sure as hell wouldn’t buy one. If they would have just slotted the four inner holes it would have been a great engineering decision.

Last edited:

Here’s a couple pictures of my spacers. Luckily I did mine on an engine stand. Now remember when I do this job it has to work on Edelbrock heads and 360-1 Indy heads. Not only that but work for a Victor340, Super Victor, and Indy intake. Now I also run two different types of valve covers, internal and external mounting bolts. So this made me slot the holes for mounting then I had to clearance not one but two set for 1.6 pushrods which was a real pain. But when they are done mark them for position and it’s a job you are probably set for life.

I don't know how any cylinder head and intake manifold port job could match up without using the block it's going to be on is used, with the head gaskets on. I'm glad I did my stuff that way or it could have caused a lot of headaches.It could be worse or let’s say it could be worse for the head porter. TrickFlow addressed this issue by slotting each hole vertically 1/4 inch. I immediately thought ohhhh man that’s a great idea until I looked and saw they slotted every dog gone hole. When a head porter get an intake the only way we can go about gasket matching it is to use a trusted gasket and match up the holes. Well when Boosted sent me his intake from Washington state to Pa to flow test and the flow numbers weren’t where we wanted then it turned into a porting job. Great until I tried to line up an intake gasket. Do I line the gasket with the top of the hole, the middle, or the bottom??? I didn’t want to risk removing metal in the wrong direction so I ended up not porting it. Now I’ll never know because I won’t take on that job and I sure as hell wouldn’t buy one. If they would have just slotted the four inner holes it would have been a great engineering decision.

I guess if the manifold and heads are scribed to the outside edge of the intake gasket shape on the head it would make it easier.

I had my long block over at Tim's when I was trying to get my tunnel ram surfaced and that made for a little pita but it worked out eventually lol

Remember how many gaskets are on my junk ?First off, I love that pushrod length. Looks about perfect.

Second...what spacers are you guys talking about and why two gaskets?? Just curious.

4 on each side plus the valley pan to get it lined up perfectly.

Edit; I misread your post I don't have valve cover spacers with 4 gaskets lol

Last edited:

I scribed my heads and intake when I first assembled and using a boroscope down the runners to validate alignment. I hope I won't have issues with my ported heads and intake.I don't know how any cylinder head and intake manifold port job could match up without using the block it's going to be on is used, with the head gaskets on. I'm glad I did my stuff that way or it could have caused a lot of headaches.

I guess if the manifold and heads are scribed to the outside edge of the intake gasket shape on the head it would make it easier.

I had my long block over at Tim's when I was trying to get my tunnel ram surfaced and that made for a little pita but it worked out eventually lol

Well that's good. Sounds like that should be fine.I scribed my heads and intake when I first assembled and using a boroscope down the runners to validate alignment. I hope I won't have issues with my ported heads and intake.

First off, I love that pushrod length. Looks about perfect.

Second...what spacers are you guys talking about and why two gaskets?? Just curious.

If you are talking about the valve cover spacers my spacer is glued to the head in position and becomes a part of that heads. Guys on here were commenting last week about using spacers and two gaskets. Why you would ever do that is beyond my thinking. Get the right size of spacer and be done with it.

Running. See the tight fit on the valve covers. I did not order this intake. Does the regular Victor not have a raised roof like this 2815 Super Victor?

The Super Victor is the worst. Especially if you try running fab covers with the bolts running through the valve cover because they are wider. I think they discontinued the non EFI part number which makes it even worst. I did this years ago to the old style manifold and I still needed spacers.

-