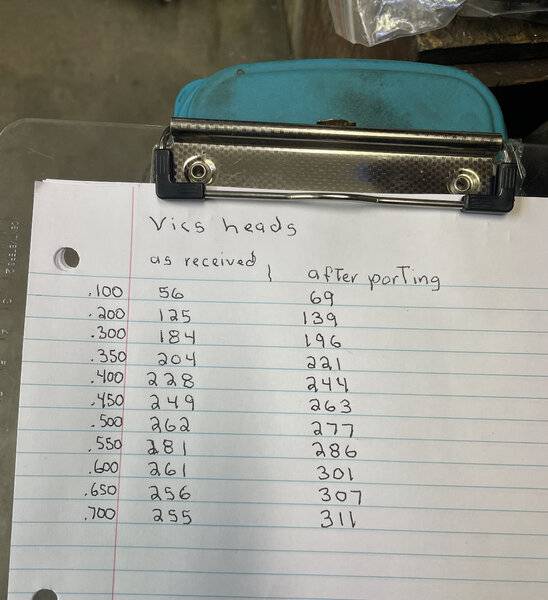

Took 6 weeks to get Manley 2.08 and 1.60 valves, keepers, LS springs (ya I didn’t stutter), spring locators, and valve locks. Well 5/16 locks came instead of 11/32. Took somewhere around 3 months to get this right minus -040 or -.050 pac 11/32 keepers needed with this spring to get the required spring pressures. The spring is only 1.280 diameter. I never do 2.08 heads for customers but this is a very good friend. Honestly I wouldn’t have done them to this size if I knew what chamber size I was limited to but with extra work they turned out ok. I was a nervous wreck assembling these small azz retainers and keepers not having a single spare but they are ready for pickup. These heads were ported by a friend before so I had a few repairs to do and had to cut them for the required .500 valve seals. Before and after numbers. Should work pretty good with his .680 lift roller cam.

Finally have this set of 2.08 Edelbrock heads done.

- Thread starter pittsburghracer

- Start date

-

They are going to borrow my Super Victor that I ran 9.70’s with years ago. I spent a couple more day’s updating it to what I do now and it flows very well.

Kendog 170

Let the boy go !

Wow that's a tight squeeze between them valves.

Wow that's a tight squeeze between them valves.

Been running mine like that since around 2010, 2012. Lol. Probably 3-4 different engines and they were used and damaged when I bought them, repaired them, and ported them. Best 350.00 investment I’ve ever made. Starting to smoke some so they are probably begging for a new set of valve guides.

abdywgn

dismantler

you are truly a master craftsman with a die grinder...and seat cutter and valve grinder and...

you are truly a master craftsman with a die grinder...and seat cutter and valve grinder and...

Just an old man making chips fly. Kinda half enjoying it too. Thanks for the kind words.

We run the LS Springs exclusively on our small block

stockers. We must run stock spring height and if there

is any challenge it is getting the spring pressure low enough

on our 318 Stockers with real Hydraulic lifters. I do not like to

see very much over 200 on the seat.

stockers. We must run stock spring height and if there

is any challenge it is getting the spring pressure low enough

on our 318 Stockers with real Hydraulic lifters. I do not like to

see very much over 200 on the seat.

abdywgn

dismantler

You are welcome. Thanks for continuing to share your knowledge and tricks of the trade.Just an old man making chips fly. Kinda half enjoying it too. Thanks for the kind words.

mgoblue9798

Well-Known Member

Wow PBR you made what was already a decent set of heads great. Interested in hearing the old vs new ETs when your friend runs them.

Wow PBR you made what was already a decent set of heads great. Interested in hearing the old vs new ETs when your friend runs them.

Me too. He ran these a couple of years ago and I’m pretty sure he was usually running 6.50’s. He was kinda disappointed last year when he ran out of the box TrickFlow heads and I’ll ask my son but I think an M1 and ran 6.66 almost all year. He races at Norwalk a lot.

B3422w5

Well-Known Member

John, off the top of your head, have any idea how much taller a super Victor is over a Victor sitting on a motor?

I’m putting together a set of 2.055 Speedmaster heads right now with regular comp keepers and retainers and it’s like I can close my eyes and relax again.

John, off the top of your head, have any idea how much taller a super Victor is over a Victor sitting on a motor?

I did I real nice post on this subject last year and measured an Indy intake, super Victor, and a Victor340. I Dont have a clean table now but working crudely on the floor it looks like with a straightedge across the plenum the super Victor is about 1 3/4 higher. In this one picture I set a one inch spacer on the Victor340 and the super Victor is still about 3/4 inch higher.

B3422w5

Well-Known Member

Thanks a bunch.

Just wondering if it would fit under my flat hood with a 1 inch spacer and a 4150 on it.

Victor 340 does, but I don’t know by how much lol…

Guess I could tape a plastic straw that extends 2 inches above the vent tubes on the carb and see if it bends when I close the hood

Just wondering if it would fit under my flat hood with a 1 inch spacer and a 4150 on it.

Victor 340 does, but I don’t know by how much lol…

Guess I could tape a plastic straw that extends 2 inches above the vent tubes on the carb and see if it bends when I close the hood

Thanks a bunch.

Just wondering if it would fit under my flat hood with a 1 inch spacer and a 4150 on it.

Victor 340 does, but I don’t know by how much lol…

I’ll have this other set of heads done tomorrow. If you need a better measurement remind me later tomorrow and I can give you more accurate measurements.

It's hard to believe there isn't a substantial gain going from the victor to the super victor.I did I real nice post on this subject last year and measured an Indy intake, super Victor, and a Victor340. I Dont have a clean table now but working crudely on the floor it looks like with a straightedge across the plenum the super Victor is about 1 3/4 higher. In this one picture I set a one inch spacer on the Victor340 and the super Victor is still about 3/4 inch higher.

View attachment 1716244329

View attachment 1716244330

B3422w5

Well-Known Member

It's hard to believe there isn't a substantial gain going from the victor to the super victor.

Have a friend with a 72 race chassis Cuda.

Been in the 7’s currently with a stout big block in the 1/4 on motor. Car is very light.

Years back he had a b1ba headed small block stroker in it. Ran 9.06-9.07 best maybe couple hundreds quicker, but consistently right around there.

Took his Victor 340 off, installed a stock Super Victor. Car slowed down a whole tenth. Think the night I saw him test it, went 9.17.

Moral of the story I guess, those things need worked to shine. Guy I am talking about never followed up doing that to the intake. Put his original intake back on, then not long after went dark side( big block)

Black Cuda, well known in these parts.

Have a friend with a 72 race chassis Cuda.

Been in the 7’s currently with a stout big block in the 1/4 on motor. Car is very light.

Years back he had a b1ba headed small block stroker in it. Ran 9.06-9.07 best maybe couple hundreds quicker, but consistently right around there.

Took his Victor 340 off, installed a stock Super Victor. Car slowed down a whole tenth. Think the night I saw him test it, went 9.17.

Moral of the story I guess, those things need worked to shine. Guy I am talking about never followed up doing that to the intake. Put his original intake back on, then not long after went dark side( big block)

Black Cuda, well known in these parts.

I never cared for the super Victor till this year. Now I really like what I’m seeing.

Ironmike

Well-Known Member

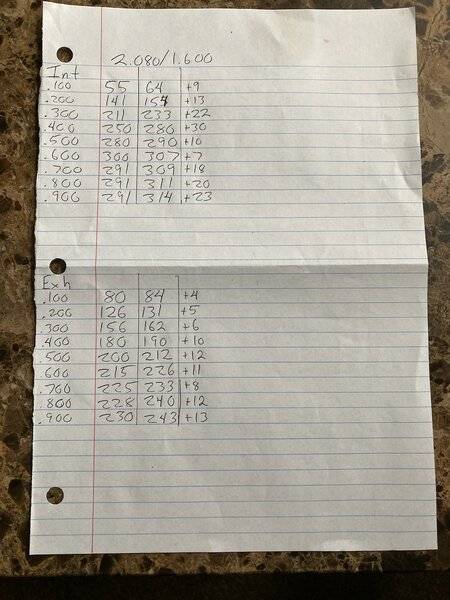

pretty good numbers. My old Eddy's just came back from a professional porter who just retired from a big name company. I got lucky to get his name. They also have the 2.08 intake. I ran them a couple years as ported by my local machinist. The new guy also did my S Victor. wish I had taken better pics, but it's all together now.

The flow sheet has the first column as ported locally. Column 2 is what the new guy did. Amazing numbers...especially mid lift. Keep in mind my bolt holes are tubed, and I run push rod oiling, so I think that explains a little.

All this preserving the short side as much as possible. He said most of the increase came from the roof and a different valve job.

The flow sheet has the first column as ported locally. Column 2 is what the new guy did. Amazing numbers...especially mid lift. Keep in mind my bolt holes are tubed, and I run push rod oiling, so I think that explains a little.

All this preserving the short side as much as possible. He said most of the increase came from the roof and a different valve job.

pretty good numbers. My old Eddy's just came back from a professional porter who just retired from a big name company. I got lucky to get his name. They also have the 2.08 intake. I ran them a couple years as ported by my local machinist. The new guy also did my S Victor. wish I had taken better pics, but it's all together now.

The flow sheet has the first column as ported locally. Column 2 is what the new guy did. Amazing numbers...especially mid lift. Keep in mind my bolt holes are tubed, and I run push rod oiling, so I think that explains a little.

All this preserving the short side as much as possible. He said most of the increase came from the roof and a different valve job.

View attachment 1716245428

View attachment 1716245429

View attachment 1716245430

Those should work nicely. My numbers are down on my last two sets because my customers held me back from what I’m used to doing as far as chamber work. Those were my last two sets of heads where the customer dictates that. A 2.08 valve should easily be over 320 cfm without restrictions on chamber. It causes me more work and not as good a set of heads for the customer.

Very nice job!Took 6 weeks to get Manley 2.08 and 1.60 valves, keepers, LS springs (ya I didn’t stutter), spring locators, and valve locks. Well 5/16 locks came instead of 11/32. Took somewhere around 3 months to get this right minus -040 or -.050 pac 11/32 keepers needed with this spring to get the required spring pressures. The spring is only 1.280 diameter. I never do 2.08 heads for customers but this is a very good friend. Honestly I wouldn’t have done them to this size if I knew what chamber size I was limited to but with extra work they turned out ok. I was a nervous wreck assembling these small azz retainers and keepers not having a single spare but they are ready for pickup. These heads were ported by a friend before so I had a few repairs to do and had to cut them for the required .500 valve seals. Before and after numbers. Should work pretty good with his .680 lift roller cam.

View attachment 1716244220

View attachment 1716244221

View attachment 1716244222

View attachment 1716244223

View attachment 1716244224

View attachment 1716244225

Ironmike

Well-Known Member

Can you get there without tubing the bolt holes? I've been running pushrod oiling for years now and think it's a better system. But i am curious.Those should work nicely. My numbers are down on my last two sets because my customers held me back from what I’m used to doing as far as chamber work. Those were my last two sets of heads where the customer dictates that. A 2.08 valve should easily be over 320 cfm without restrictions on chamber. It causes me more work and not as good a set of heads for the customer.

Can you get there without tubing the bolt holes? I've been running pushrod oiling for years now and think it's a better system. But i am curious.

I tube and redrill the two common wall bolt holes on every head I port. With a 2.08 valve I’m at 334 cfm so far on a set of heads I’m working on for my duster. I could never offer a set like this to customers because of the time involved. The set I’m running now I did in 2008 and max out at 318 with the intake on and would run 9.30 in the 1/4. I’ve changed things a lot since then including my ability to do a good valve job.

-