You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

full floating wristpins vs. pressed wristpins

- Thread starter 2264ply

- Start date

-

RAMM

Well-Known Member

Not really IMO. Just ease of assembly/disassembly. Some claim a few HP at high RPM--I can't say I've ever witnessed that. J.Rob

Get the floating pins. If the pressed pins ever happen to move and seize they can score the cylinder walls!

MisterFiberglass

Member

Get the floating pins. If the pressed pins ever happen to move and seize they can score the cylinder walls!

MORE of a chance of one of the keepers blowing out and that happening IMO.

MORE of a chance of one of the keepers blowing out and that happening IMO.

Floating pins don't necessarily free up horsepower as much as they relieve a little stress and friction. Stupid as it sounds, they allow some extra movement for the piston to minutely "rock" back and forth in the bore and that action relieves a little stress on the entire small end of the rod. I've seen some "machine" shops set up floating rods just by honing the little end until the pin will slide through and go steel on steel. I have always advised against that. Go the extra mile and bush the small end of the rod. You won't regret it. ....but like has been said before, I am not even sure you'd see the difference on the dyno. It is more of a durability/heavy duty type thing.

412 Stroker

Well-Known Member

StrokerScamp, then you like pressed better than floating?? or does it depend on the application??

I have run several sets floated with no bushings in circle track motors and had zero troubles. also drilled a small chamfered oil hole in the top of the rod to oil the pins. I have never seen a spirolok that was properly installed come out either?

StrokerScamp, then you like pressed better than floating?? or does it depend on the application??

I much prefer floating than pressed.

I have run several sets floated with no bushings in circle track motors and had zero troubles. also drilled a small chamfered oil hole in the top of the rod to oil the pins. I have never seen a spirolok that was properly installed come out either?

I just said I advised against it, not that it couldn't be done. Just my personal preference.

pishta

I know I'm right....

floaters all the way. Spiroloks and all. Save 8 bucks a rod by not having them hang them for you, and pressing out a pin always runs the risk of damaging the piston, ask your machinist. Too bad all aftermarket pistons are not machined for locks.

1970Duster

Well-Known Member

- Joined

- May 30, 2010

- Messages

- 6,644

- Reaction score

- 219

I have Forged Eagle H-Beam rods (I don't trust their I beams either cast or forged) with Ross Racing Pistons (these are floating) in my 340.

Scat I and H beam roads are good as well.

Scat I and H beam roads are good as well.

RAMM

Well-Known Member

I have Forged Eagle H-Beam rods (I don't trust their I beams either cast or forged) with Ross Racing Pistons (these are floating) in my 340.

Scat I and H beam roads are good as well.

Yeah--ALL rods in the aftermarket are forged. NOBODY produces a cast rod. J.Rob

nqkjw

Well-Known Member

I've seen some "machine" shops set up floating rods just by honing the little end until the pin will slide through and go steel on steel. I have always advised against that. Go the extra mile and bush the small end of the rod. You won't regret it..

Can I ask why?

I built a 460 fraud for a mate back in about 1985 with just the little end honed and had no dramas.I did drill and chamfer a 1/8 hole in the top of the rod for oil feed.

I don't really know if it's good or bad practice hence my asking why you don't like it.

Look at crank bearings, for instance. Are the bearings the same material and hardness as the crankshaft? No. They are softer. The connecting rod is not designed to be a bearing. Bearings should be of a softer material than what they support. That's why bronze bushings are used in full floating applications and also why you never see a factory floating connecting rod that's not bushed. You're right. You may never have trouble with honing the rod and using it with no bushing. But like metals are more prone to galling. That's the whole purpose of a bearing or bushing.

Can I ask why?

I built a 460 fraud for a mate back in about 1985 with just the little end honed and had no dramas.I did drill and chamfer a 1/8 hole in the top of the rod for oil feed.

I don't really know if it's good or bad practice hence my asking why you don't like it.

dodge freak

Well-Known Member

The 340's all came with floating pins, must have been for a good reason.

No timing chain tensor's either

No timing chain tensor's either

green1

Well-Known Member

Like stroker said; full is a bearing.Thing about it, the piston/rod have to swivel as it goes up and down in the bore.

Reviving an old thread instead of starting a new one, as I have similar questions.

The 340 I'm doing has 3418645 con rods with bushings in small end. Is it feasible/worth it to drill oil hole on small end THRU the bushing?

How do you tell floating pins vs pressed pins? Pins I have are 2.998" long and 0.984" OD

Thanks!

The 340 I'm doing has 3418645 con rods with bushings in small end. Is it feasible/worth it to drill oil hole on small end THRU the bushing?

How do you tell floating pins vs pressed pins? Pins I have are 2.998" long and 0.984" OD

Thanks!

The pins are the same size, pressed or bushed. It's the rod that's different. Yes, you can drill the oil hole right through and then dress the hole with some 600 grit wet or dry.

Thanks Rob. Od rather revive an old thread vs starting a new one.

I would do this myself as I have access to good drill.presses. 3/16" size.hole?

I would do this myself as I have access to good drill.presses. 3/16" size.hole?

The pins are the same size, pressed or bushed. It's the rod that's different. Yes, you can drill the oil hole right through and then dress the hole with some 600 grit wet or dry.

Thanks Rob. Od rather revive an old thread vs starting a new one.

I would do this myself as I have access to good drill.presses. 3/16" size.hole?

I think that's sufficient. Some say the holes are not needed, but my view is, the more oil the better.

nm9stheham

Well-Known Member

Your pistons also ought to have grooves for the pin locks inside the pin bores of the pistons, near the other ends of the pin bores.How do you tell floating pins vs pressed pins? Pins I have are 2.998" long and 0.984" OD

Thanks!

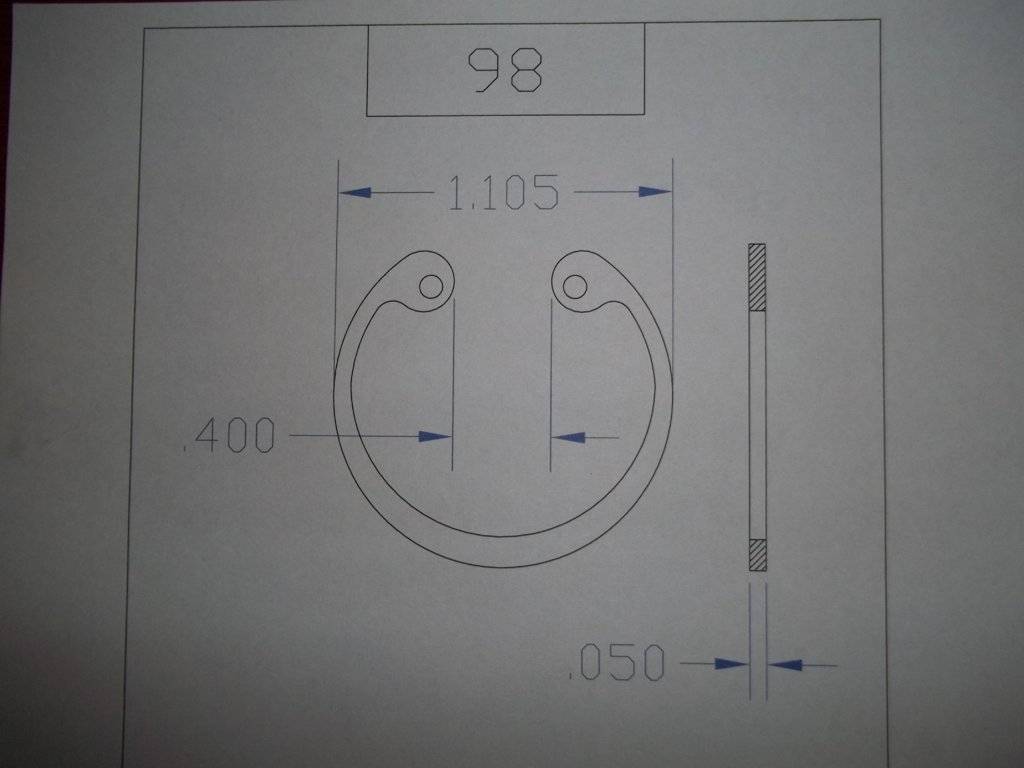

If the style of clip that gets used looks like this (see pic) there is a right way and a less right way to be installed. Look really close to how the clip is made, there is a slight contour to it's shape, put the "rounded" surface towards the pin and there for the more "sharper" edge will face outward possibly helping preventing the clip from ever coming out. Also "clock" the end gap to the 12 o'clock or 6 o'clock position, this reduces the likelihood of the clip coming out due to the reciprocating forces being a factor.

Krooser

Building Chinese Free Engines since 1959...

I have two sets of high dollar Pankl H-beam rods out of a NASCAR RO7 engine and these are steel on steel non-floating rods... kinda surprised me, too.

So I talked with my friend Jim Watson (RIP) who was a crankshaft specialist for Roush racing for eight years. He confirmed that they run those rods non floating without a bushing in the Ford RY engines, too.... my rods show that heat was used to press the rods on and off.

My dirt 383 small block has bushed 340 rods...

So I talked with my friend Jim Watson (RIP) who was a crankshaft specialist for Roush racing for eight years. He confirmed that they run those rods non floating without a bushing in the Ford RY engines, too.... my rods show that heat was used to press the rods on and off.

My dirt 383 small block has bushed 340 rods...

-