Longgone

John/68 Barracuda & Dart

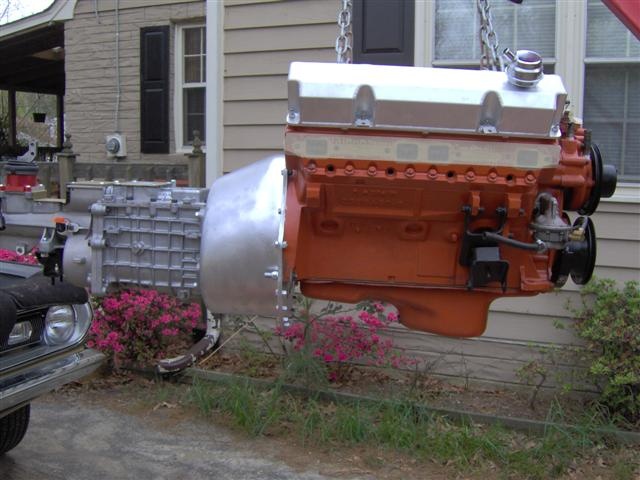

Finally things are coming together for the Goldfish. She`s been down since late Dec., `06 and is getting a new drivetrain.The engine, with it`s new rotating assembly (499 cubic inches), heads, cam, and headers is ready and will be joined in HOLY#$%^ matrimony to the Tremec 5 speed and gently shoehorned into the engine bay.(How do people ever fit Hemis in these things?) I`ll be adding a hydraulic clutch and 3" exhaust. I`ve just got step one taken care of ,that is getting the driveline in the car. I`ll have to mount the intake, alternator, fan and radiator this weekend. The headers will have to wait for now. I have to break in the engine with the stock exhaust manifolds, readjust the valves and retorque the heads. The new valve covers can only be removed if I unbolt the heater box, yup......you heard right, the heater box. I think they might have to go! Anyway here`s a few pix of todays progress.