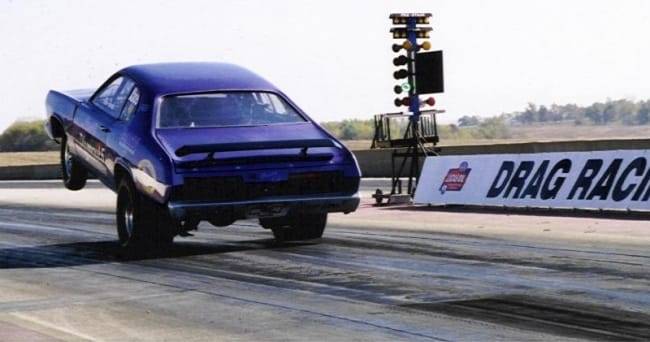

I don't have engine photos but a buddy put this teen together. It's a + .030 318, W2's, Enderle Injected/methanol, 5500 stall, Glide, 4.88's in a 9", 2750 with driver. It ran 9.95 @ 135. Teens can work!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Hypothetical 318 Builds

- Thread starter RustyRatRod

- Start date

-

30+ more hp with a bigger carb.85 la roller cam 318, magnum heads with port work, kb hypo flat tops 0 deck .035 head gaskets so some wheres around 11.5 compression, big mutha thumper hr cam 235/249 @ 50 522/509 that will bleed off compression to a barley pump friendly level with good quench, should be ok! hughs spring kit, strip dom intake and a worked holly 650 duel line mechanical 2nds, too much compression, tooooo much cam, going in a 73 duster drag/grudge/street deal with 4:10 gears slicks and a stall, been scrounging for years bout 800 in so far and looking at 1800 tottle budget, and tired of waiting, saving for pistons now, then we'll find out!

HankRearden

Well-Known Member

I've been kicking this around for a daily driver fuel economy build.

I have a locked up 79 318 that I need to autopsy. But I'm thinking stock rodd and pistons. Mill block for zero deck. Stock reman magnum heads drilled for la bolt pattern

Windage tray and crank scraper to reduce parasitic losses and cam designed for torque.

Weiand dual plane and old Holley economaster or 500 edelbrock.

Not remotely close to a race machine but in a sub 3000lb mini truck with a 5 speed should get good fuel mileage and fry tires.

I have a locked up 79 318 that I need to autopsy. But I'm thinking stock rodd and pistons. Mill block for zero deck. Stock reman magnum heads drilled for la bolt pattern

Windage tray and crank scraper to reduce parasitic losses and cam designed for torque.

Weiand dual plane and old Holley economaster or 500 edelbrock.

Not remotely close to a race machine but in a sub 3000lb mini truck with a 5 speed should get good fuel mileage and fry tires.

Stock pistons are too far in the deck to mill the block to zero.I've been kicking this around for a daily driver fuel economy build.

I have a locked up 79 318 that I need to autopsy. But I'm thinking stock rodd and pistons. Mill block for zero deck. Stock reman magnum heads drilled for la bolt pattern

Windage tray and crank scraper to reduce parasitic losses and cam designed for torque.

Weiand dual plane and old Holley economaster or 500 edelbrock.

Not remotely close to a race machine but in a sub 3000lb mini truck with a 5 speed should get good fuel mileage and fry tires.

HankRearden

Well-Known Member

You are probably correct. We did one years ago and .090 got us there but it may have been a different year with s different oe piston.Stock pistons are too far in the deck to mill the block to zero.

That'll hurt some larger engine's feelins right there.Here's one I built last year but haven't gotten to getting it in the car & running yet (car stuff has gone on hold due to having a baby).

73 318 block bored .060" over, factory cast crank ground 20/20, reconditioned factory rods fitted with ARP bolts & setup for floating pins, KB167s 0.013" above deck (0.051" head gasket), rotating assembly ballanced, HV oil pump, windage tray & baffled oil pan. Heads are bare China castings with a light home port job, valve job was redone on a newen cnc and assembled with ferrea valves, lunati beehive springs, B3 geometry kit and PRW 1.6 rockers.

Intake is a ported weiand action plus with 650cfm AVS2, exhaust will be headers and a twin 2.5" system.

9.8:1 compression ratio, rollmaster gold timing set & howards SFT cam [email protected]" & .574" lift with the 1.6 ratio rockers.

View attachment 1716144700

Looks like may be 400 + horse. It might like a little bigger carb though.That'll hurt some larger engine's feelins right there.

I agree! I'd like to see a 750 Street Demon on it.Looks like may be 400 + horse. It might like a little bigger carb though.

I like the looks of those!I agree! I'd like to see a 750 Street Demon on it.

New one sitting here waiting for me to get my motor in... Soon! (tm)I like the looks of those!

He specs are very similar to the top magnum headed 400 hp 318 on post #18Looks like may be 400 + horse. It might like a little bigger carb though.

dirty white boy

50 yr old Juvenal delinquent

ol carb flows like a 750, got 750 base plate, center hung floats and other work, was my dirt track carb witch rules state gotta have numbers on horn stating its 650, but im sure itll out flow most 750s!!30+ more hp with a bigger carb.

dirty white boy

50 yr old Juvenal delinquent

yes,..but,..maybe not!! depends on witch stock 318 pistons he has, the early pre 69 318s had 9.5 pistons with eyebrows, the post 85 318s had flat top 9.5 pistons thay should be close to .040 below deck and cutting a 0 deck is do'abile!! another way to skin that same cat, or work with it, is buy .060 over sized bearings and off set grind crank and get .030 closer to 0 deck! just depends on what you got and whats available to you...easyest, best money spent is a cheap set of 0 deck hypos and good fresh bores for best running longest living engine!!Stock pistons are too far in the deck to mill the block to zero.

Or just buy some proper pistons because you are boring the block anyway. KB167's.yes,..but,..maybe not!! depends on witch stock 318 pistons he has, the early pre 69 318s had 9.5 pistons with eyebrows, the post 85 318s had flat top 9.5 pistons thay should be close to .040 below deck and cutting a 0 deck is do'abile!! another way to skin that same cat, or work with it, is buy .060 over sized bearings and off set grind crank and get .030 closer to 0 deck! just depends on what you got and whats available to you...easyest, best money spent is a cheap set of 0 deck hypos and good fresh bores for best running longest living engine!!

dirty white boy

50 yr old Juvenal delinquent

easyest, best money spent is a cheap set of 0 deck hypos and good fresh bores for best running longest living engine!!Or just buy some proper pistons because you are boring the block anyway. KB167's.

dirty white boy

50 yr old Juvenal delinquent

ive figured it dollar for dollar,..penny for penny,... plus you gonna run it harder, you need a better than stock piston if you want it to last! also be easyer to fix if some thing dose go bad you ant commented to a one off machined engine...

MILO

Well-Known Member

For me my 273 LA the biggest help was camshaft second was duals 3rd was 4 barrel that little dart with 4 speed would scream and wind high a real good runner that would make most very happy without breaking the bank

Zcuda68

Well-Known Member

Thank you for posting JUST a 318 post and made it clear no stroker or "just buy a 360" talk allowed. Posts can get so convoluted with that stuff. Guy asks a questions about a 318 and it always turns to "just buy a 360"There's been a lot of 318 talk recently, so I thought what better way to have a little fun than have a hypothetical 318 built thread? Just a couple of rules. Must be stock 3.31" 318 stroke and "whatever" bore. Whatever heads, cam and pistons is fine, but no stroker. You start talkin stroker this and that or "use a 340 or 360" go start your own thread. Also, this thread is for naturally aspirated builds. No power adders like blowers, turbos and nitrous. Go start your own thread. This is to help guys with 318 builds get a good idea of what they are capable of. So with that in mind, here is my recipe for "around" 300-325HP 318 build.

I would start with a 5.2 Magnum engine since the LA platform is so old now, decent cores are getting pretty tough to find. Also, we have the advantage of a factory hydraulic setup and 1.6 rockers. With that in mind,

9.5:1 blueprinted compression ratio. Stock Magnum 1.920/1.625 360 (Thanks @66fs) valves in the Magnum heads with bowls blended nicely. If you can afford to port the rest of the way, or do it yourself, knock it out, but it's not necessary. A good quality multi angle valve job is a must.

For camshaft, I'm ASSUMING since you want a hot 318 that you're gonna want to rev it some and play around so I'm choosing a pretty stout grind. Grind #1408 on the Oregon Cam hydraulic roller list. .480 lift both sides, 224@ .050" intake and 230@ .050" exhaust, but we're gonna get them to grind it on a 106. They will do that no charge. We will use stock Magnum lifters. They last a long time, so if you find a good used set, more power to you. We'll utilize the Hughes Engines 1110 valve spring.

On rocker arms, I like adjustability and IMO, the most cost effective is the kit Hughes Engines sells.

ROCKER ARM KIT

Might be cheaper ways, but this gives you everything you need in one fell swoop and it's pretty nice.

As for intake mannyfold, I like the air gap style. The port match to the heads is important, so you'll need to include having the heads and intake port matched in the budget. Well worth the money. If you want to go further, and can do it yourself or afford it, great, but all I'm calling "necessary" with this build is the port matching. With that in mind, get the genuine Edelbrock if you want, or the chinkese knock off, it really doesn't matter.

Just like with the camshaft, I'm assuming you're gonna run this little beeotch, so I'm gonna choose a Quick Fuel Brawler 650 dual line double pumper.

On the ignition, all yall know I like the stock Mopar style electronic ignition. I recommend sending the distributor to @halifaxhops Ray and he will hook you up with a good hot ignition curve. He can even fix you up with a good, NOS quality ignition ECU box, or the other I recommend is the "HI Rev 7500" available at Jegs. I got mine off Amazon and it came in a Jegs box.

As for exhaust, again, we're not buildin a pussy 318, so this gets headers. I recommend the biggest primary tube header you can afford and also a complete 3" exhaust to the rear bumper with constant diameter mufflers "of some kind".

This should actually about cover it. You WILL have an honest 300-325HP and possibly more depending on how far you want to go with port work.

So that's my recipe for a good hot, reliable 318. What's yours?

1969 318 hone,ring, bearings and second to the smallest purple cam at the time? Been a while. Heads mild Port work. If any gain likely taken away with manifolds. Heads rebuilt with springs to match cam. Street master intake, 4 barrel and windage tray. Mopar performance electric ignition.

On the mild side. Performed well and got 20 mpg on the highway. Good balance between power and efficiency

On the mild side. Performed well and got 20 mpg on the highway. Good balance between power and efficiency

Perfect. They all don't all have to be 400 horse.1969 318 hone,ring, bearings and second to the smallest purple cam at the time? Been a while. Heads mild Port work. If any gain likely taken away with manifolds. Heads rebuilt with springs to match cam. Street master intake, 4 barrel and windage tray. Mopar performance electric ignition.

On the mild side. Performed well and got 20 mpg on the highway. Good balance between power and efficiency

Just thinking, back in the day Mopar didn't advertise horsepower like Chevy did. Back in the mid to late 60's and early 70's, a 300 horse 327 was a damn good runner. The 350 horse in a Corvette was an animal. Oh, and the 350 horse 350 was a good one too. See what they did there? 350 horse out of a 327 and a 350. Just like us here. Go build your 300 horse Teens and go have fun.

I just built one for a Mopar mate with Coronet.

1968 318LA at +30 with old school forged TRW's.

1966/7 closed chamber 273 heads with 1.88's and 1.60's

Compcams 1/2'' lift and 273 adjustable rockers.

He asked if it would make 300hp???

Maybe with some decent gas lol...

ps I got the pistons outta a marine engine, low nautical miles.

1968 318LA at +30 with old school forged TRW's.

1966/7 closed chamber 273 heads with 1.88's and 1.60's

Compcams 1/2'' lift and 273 adjustable rockers.

He asked if it would make 300hp???

Maybe with some decent gas lol...

ps I got the pistons outta a marine engine, low nautical miles.

My next teener will be with 'J' heads and another set of forged TRW's, yep outta another mariner engine!

Steel crank from a 273 and 340 rods that have been lightened and polished etc.

I want to get her up to around 7500rpm's hopefully.

I just love a screamer...

Steel crank from a 273 and 340 rods that have been lightened and polished etc.

I want to get her up to around 7500rpm's hopefully.

I just love a screamer...

I'm keeping mine under 6000... you guys have much larger balls than iMy next teener will be with 'J' heads and another set of forged TRW's, yep outta another mariner engine!

Steel crank from a 273 and 340 rods that have been lightened and polished etc.

I want to get her up to around 7500rpm's hopefully.

I just love a screamer...

-