Damn and I sold all my harnesses.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

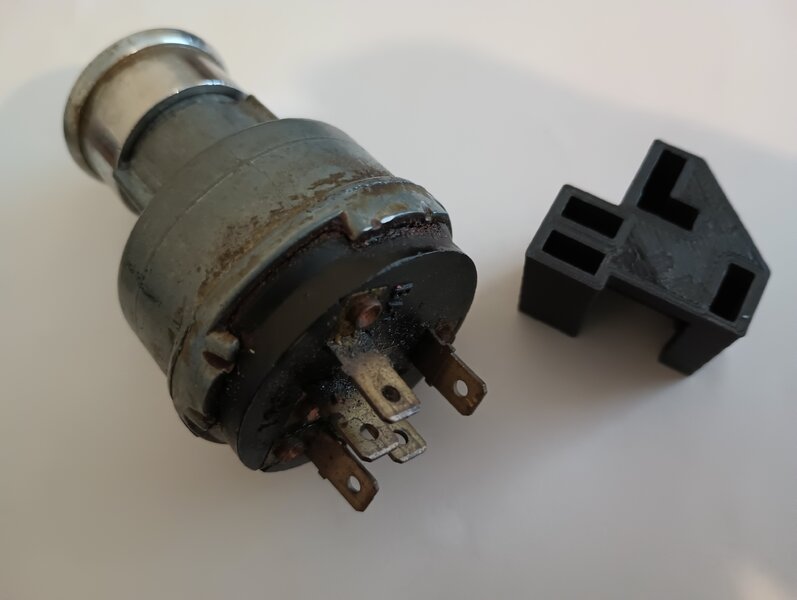

Ignition Switch Connector (or pigtail)

- Thread starter Jim Kueneman

- Start date

-

As long as the pins are correct don’t care about the clips. This is an A100 and has no clip.

And a lot more fun than individual connectors.As long as the pins are correct don’t care about the clips. This is an A100 and has no clip.

- Get a paper towel tube.

- Cut it to wrap around the ignition switch tight, use a hose clamp and/or tape to hold it on and tight

- Take some pam and spray it on the back of the ignition switch and the inside of the cardboard (alternately you could make slits in some plastic that match up with the terminal pattern and place it over the switch)

- Put individual connectors on the wires

- Put each wire on the correct terminal of the switch

- Fill the cardboard tube with high temp silicone and allow to FULLY cure

- Remove the card board

- Remove the terminals and the silicon

- Clean the pam off the parts / terminals etc with alcohol

- Reassemble.

MadScientistMat

Well-Known Member

- Joined

- Mar 6, 2008

- Messages

- 703

- Reaction score

- 302

Starting some work on it. This one has a few obvious mistakes, but the holes line up...

Starting some work on it. This one has a few obvious mistakes, but the holes line up...

View attachment 1716225966

Are you trying to 3D print the connector?

I saw a member on FBBO (JimKueneman) is setting up to make the plastic wire connectors.

Yes posted here in the Electrical section too. Should have my prototypes in 10 days.

MadScientistMat

Well-Known Member

- Joined

- Mar 6, 2008

- Messages

- 703

- Reaction score

- 302

I'm printing a prototype, but if I put them into production I plan to use polyurethane molding.

Any update on ignition switch connector?

ignition came out great. I can put it up on Shapeways if you want one.

67Plymouthbarracuda

Well-Known Member

Do you have a link? Any chance you did the headlight switch connector also?ignition came out great. I can put it up on Shapeways if you want one.

67Plymouthbarracuda

Well-Known Member

I have access to a 3D printer if you have the .stl files

Shapeways went out of business and deleted all the models. I have the model PM me.

STL file.

67Dart273

Well-Known Member

Actually you don't really NEED the connector, at least temporarily, if you have some good insulated (or heat shrink) flag connectors. Just individually install them, and be careful not to pull on the harness.

-