PRH

Well-Known Member

What was the valve diameter, throat diameter, bowl diameter when you were at this stage?

240's tops with a short turn like that.As a baseline, what does a stock 2.02 head flow on your bench?

What did that big raised port flow in that configuration, and with what sized valve?

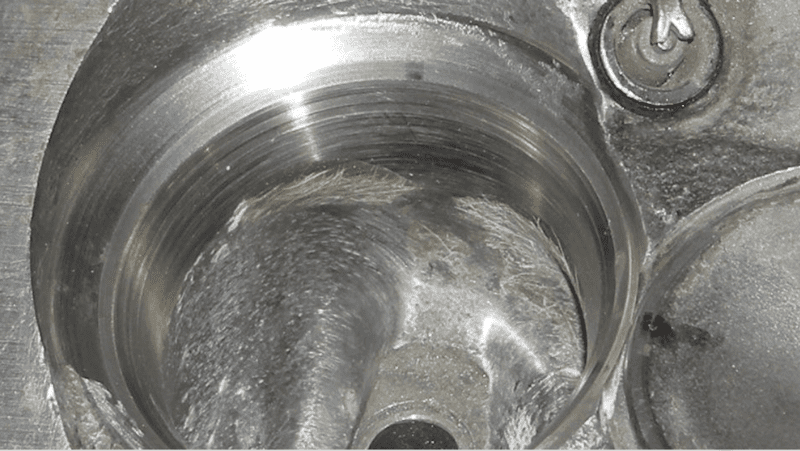

That really rounded shape to the floor at the short turn has never works for me.

View attachment 1715469738

More armchair quarterbacking.......

Imo...... you haven’t taken enough off that lump in the roof next to the guide boss, in the head bolt area.

That material needs to be completely removed for the “high effort” type jobs.

Along with more material removed behind the guide, making for more of a “boat tail” type shape.

View attachment 1715469745

Out with the 340 & in with the 410 stroker!More armchair quarterbacking.......

Imo...... you haven’t taken enough off that lump in the roof next to the guide boss, in the head bolt area.

That material needs to be completely removed for the “high effort” type jobs.

Along with more material removed behind the guide, making for more of a “boat tail” type shape.

View attachment 1715469745

I agree 100%. But we both know that is a massive bunch of work. And we both know grinding sucks, and grinding cast iron double sucks.

If you want the power, you need to do the work.

Oh, for sure it’s way more work than I’d take on.

But it looks like that’s a “test head”, so it’s not so bad only doing one port to test the theories.

With “normal” porting...... no holes, no sleeves, no extraordinairy measure......... an X head can get into the 270’s, and not have the numbers get too terrible at the top end of the flow curve.

I’m more conservative at the short turn on the 915 and later heads....... as I prefer not finding water there.

Hard seat all the intakes , cheap if you can do it youself. Port to the seat id, not too wide up in the bowl, just deepen it there. 265-275 from a 915 J.Yep. I'm a cringing chicken around the short turns on those myself.

I wonder what that bowl looked like, a dunce cap, or maybe a bucket.I have know idea why i didn't get a notification that some one had posted up on my thread.

Not Ignoring you all. just stumble on it. and i'm glad.

Ok first Yes this is a test head.

PRH i will dig up my notebook and see if i can match a pic to my notes so i can answer you questions.

But to start with.

Here is the history of this particular head and how it got to this state.

Started out on my first 340. 360 head 974 w/188. Dropped a intake valve and destroyed my cyl block.

New motor, same head with one hardened intake seat and 8 exh hardened seats. bowl blend to hardened seat on one intake and exh. made plastic templates so i could make all the rest of the bowls the same. This was the first time with a die grinder and a cyl head.

Head before would rev 6000 rpm after porting would rev to 7200 RPM same compression same cam same everything. head was the only thing different. Was a dog at the track and ran a full sec SLOWER! Acted like a 2 stroke and had no power until 4000 rpm and then just took off. And it wouldn't pass emission either.

Pulled them and put a stock set of X head on it and was happy. had bottom end shift a 5800 rpm.

So after i builts my first real(????) porting bench. i when a searching for these head.

When i first get these number for you. you have to understand, that this bench was to small and after 300 lift i had to drop from 28" down to 10 and do the math from there to represent 28"

I was vary good at making turbulence in these ports and at 10" it was hiding a lot of it.

I don't know but i can tell you it was less them before i put the 2.02 Valve in(eats up way to much csa at the ssr.)As a baseline, what does a stock 2.02 head flow on your bench?

What did that big raised port flow in that configuration, and with what sized valve?

That really rounded shape to the floor at the short turn has never worked for me.

View attachment 1715469738

Unfortunately i didn't do a good job marking my pic's to the time in my notes.What was the valve diameter, throat diameter, bowl diameter when you were at this stage?

View attachment 1715469744

More armchair quarterbacking.......

Imo...... you haven’t taken enough off that lump in the roof next to the guide boss, in the head bolt area.

That material needs to be completely removed for the “high effort” type jobs.

Along with more material removed behind the guide, making for more of a “boat tail” type shape.

View attachment 1715469745

I wonder what that bowl looked like, a dunce cap, or maybe a bucket.

Any pics?

That port, i ended up porting out to 200 CC port with 2.19 bowl. Flowed [email protected] and 270@600(after figuring out the chambler problems)

All i can do is rely on my notes, because this was done back in 2010.

However, i found my mistake.

The bowl is only 1.71" the 2.19 was the throat area, figuring in from the 1.71" bowl with 3/8 valve stem.