I give up.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

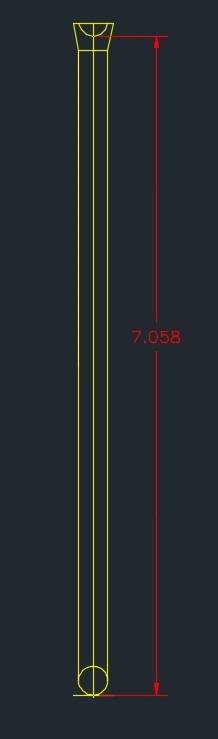

Pushrod for hydraulic cam and 273 rocker arms

- Thread starter krazykuda

- Start date

-

I give up.

I hear ya... It sucks when the "Tech" guys can't give accurate information when you order parts...

I hear ya... It sucks when the "Tech" guys can't give accurate information when you order parts...

I said that because I have recommended several times now to measure with a checking pushrod, find the correct length with that, lock it down, send it to Comp......or whomever and get THE RIGHT LENGTH pushrods made.

Continuing to order more pushrods without measuring only increases your chances of getting what is it? 4 incorrect sets of pushrods?

There is only ONE way to do this with a 100% success rate and measuring is it. Any other way and you are simply guessing.

nm9stheham

Well-Known Member

If you do what #2 said, then subtract 5/16" from the measurement. The point is to get to the type of measurement that the first guy told you: tip of ball to bottom of cup ==> effective length... for SOME manufacturers.One tech guy at Summit said to measure to the bottom of the cup to the tip of the ball on the opposite end...

Tech guy #2 said to measure the push rod with a 5/16" ball in the cup and go from tip of ball to tip of opposite ball....

You gotta look at the manufacturers specs to see how they spec them. Forget a distributor's data: go to the manufacturers data sheets. In the case of Comp, you have to look at their comprehensive catalog. For the 7821's they list the length as 'overall length".

Last edited:

If you do what #2 said, then subtract 5/16" from the measurement. The point is to get to the type of measurement that the first guy told you: tip of ball to bottom of cup ==> effective length... for SOME manufacturers.

You gotta look at the manufacturers specs to see how they spec them. Forget a distributor's data: go to the manufacturers data sheets. In the case of Comp, you have to look at their comprehensive catalog. For the 7821's they list the length as 'overall length".

I hear you.

What we were told by the techs over the phone on rod length was not true when the push rods got here. They didn't know what they were talking about.

I said that because I have recommended several times now to measure with a checking pushrod, find the correct length with that, lock it down, send it to Comp......or whomever and get THE RIGHT LENGTH pushrods made.

Continuing to order more pushrods without measuring only increases your chances of getting what is it? 4 incorrect sets of pushrods?

There is only ONE way to do this with a 100% success rate and measuring is it. Any other way and you are simply guessing.

Sorry Rob.

We were trying to see if we could do it with the instruments that we have.

The checking push rod would be the best way to go, but he's in a hurry to get this going so I tried to measure as best that I could with my calipers.

I think my numbers are right for length, but they sent us literally the same exact push rod length, but another manufacturer for about $100 more. They were supposed to be shorter than the first set, but turned out not to be.

Eddie has sent our drawing to the custom push rod guys and is trying to see how fast they can get a set out.

I completely understand. I have gotten in a hurry before myself on projects, but it has never paid off. Yall might luck up and guess right. But, you have three incorrect pushrod sets now. IMO, it's best to go ahead and take the extra time and get it right, 100%.

I completely understand. I have gotten in a hurry before myself on projects, but it has never paid off. Yall might luck up and guess right. But, you have three incorrect pushrod sets now. IMO, it's best to go ahead and take the extra time and get it right, 100%.

I'm half tempted to find an old push rod and cut it and put some threads in it to check for length...

Or I could use one of Eddie's $10 each ones for the "mock up".... (It would also be cheaper than the $20 "checking push rod"....)

nm9stheham

Well-Known Member

Either way would work; the cutting up and threading of the old one would be a very good idea. Put a coupla lopcknuts in it, and away you go.I'm half tempted to find an old push rod and cut it and put some threads in it to check for length...

Or I could use one of Eddie's $10 each ones for the "mock up".... (It would also be cheaper than the $20 "checking push rod"....)

Yes, on the tech support guys; they do their best, buuut.....IIRC, the Smith Brothers site has a good write-up on how to measure and how they spec lengths.

Here's the latest update:

We did get a measuring push rod and measured each 5 times to get a good average length. We ended up needing 7.058" from cup to ball.

We ordered a set, and they came. We measured them to be average of 7.064" +/- .005" from cup to ball and installed them....

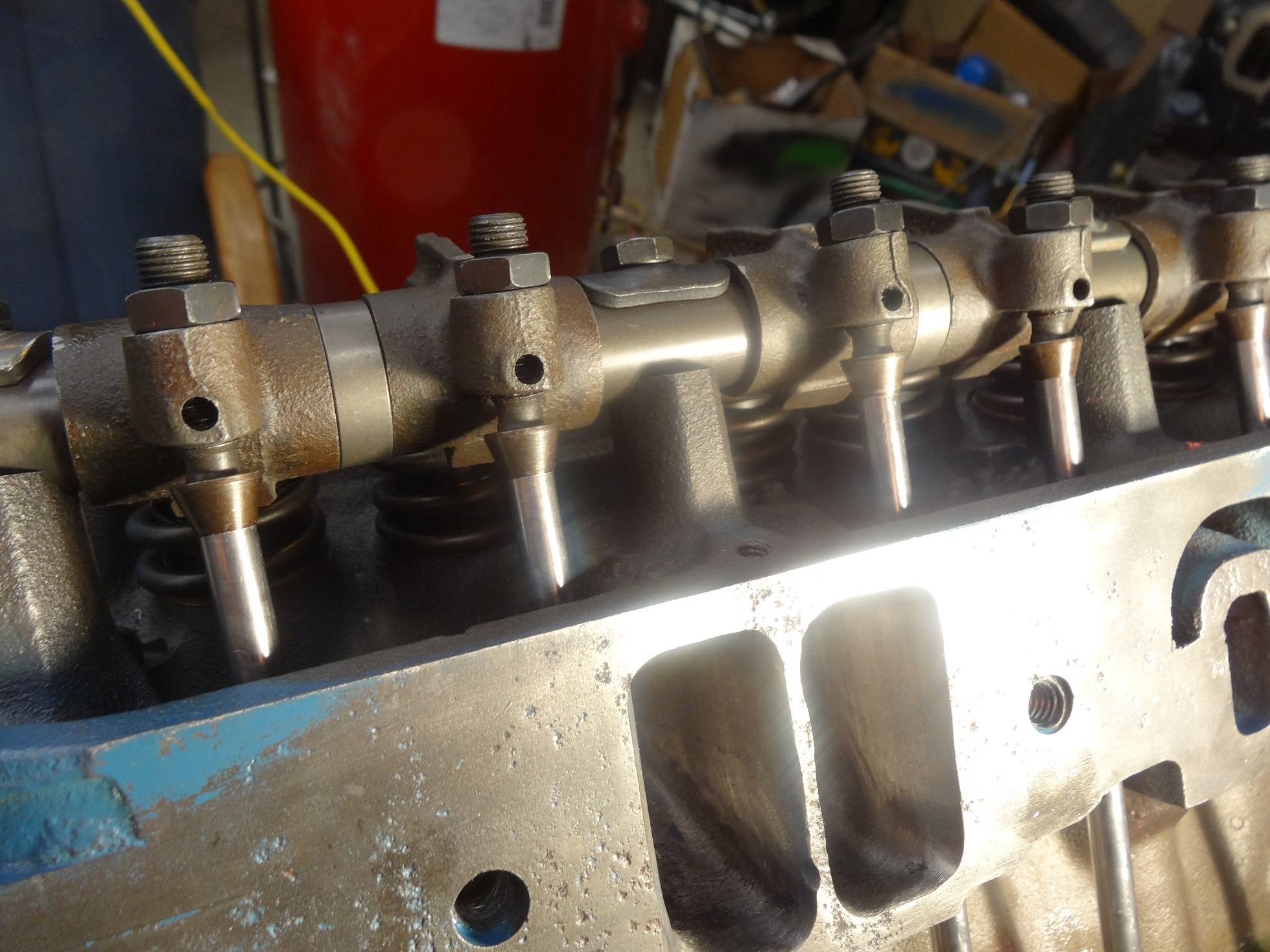

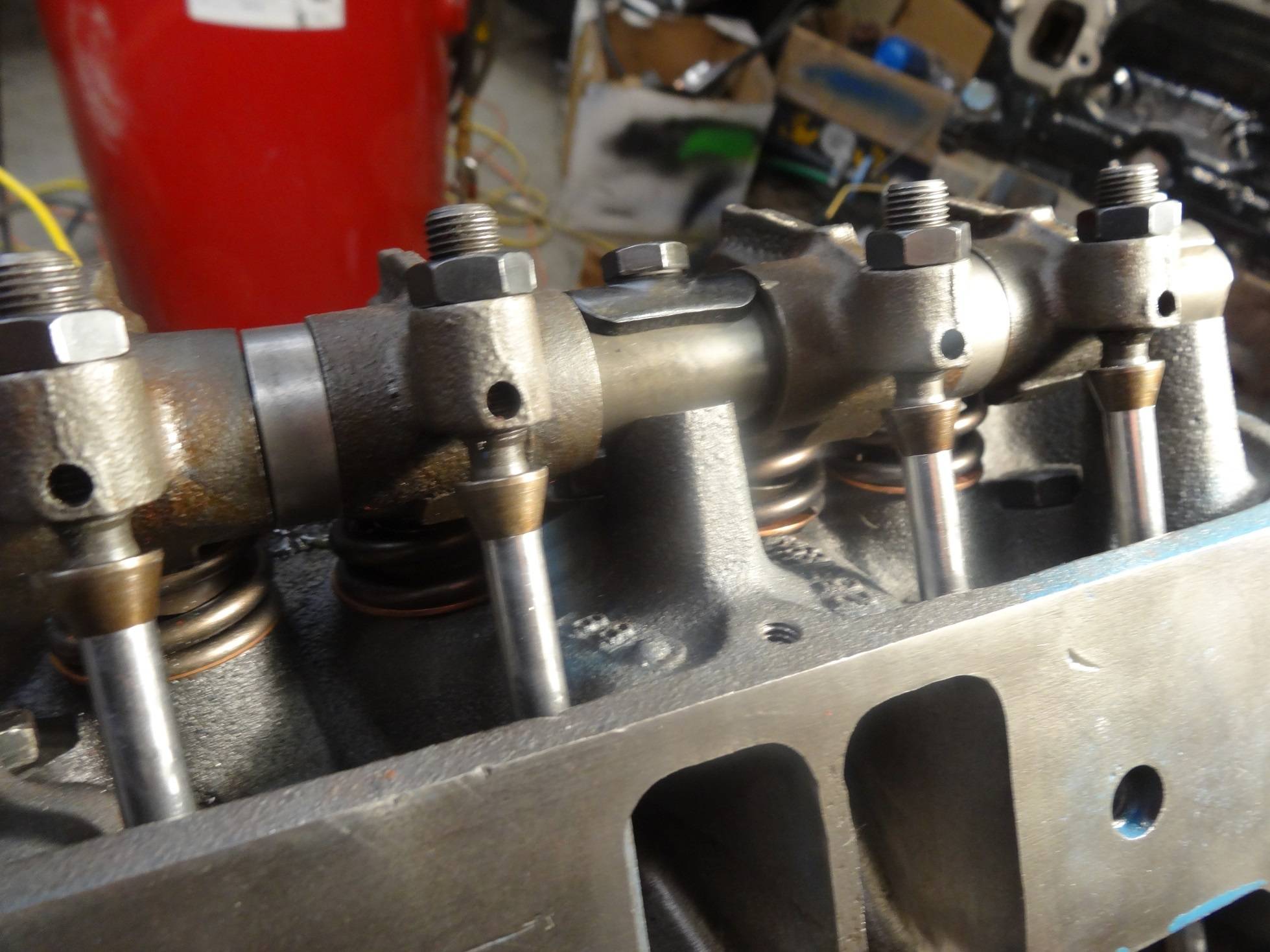

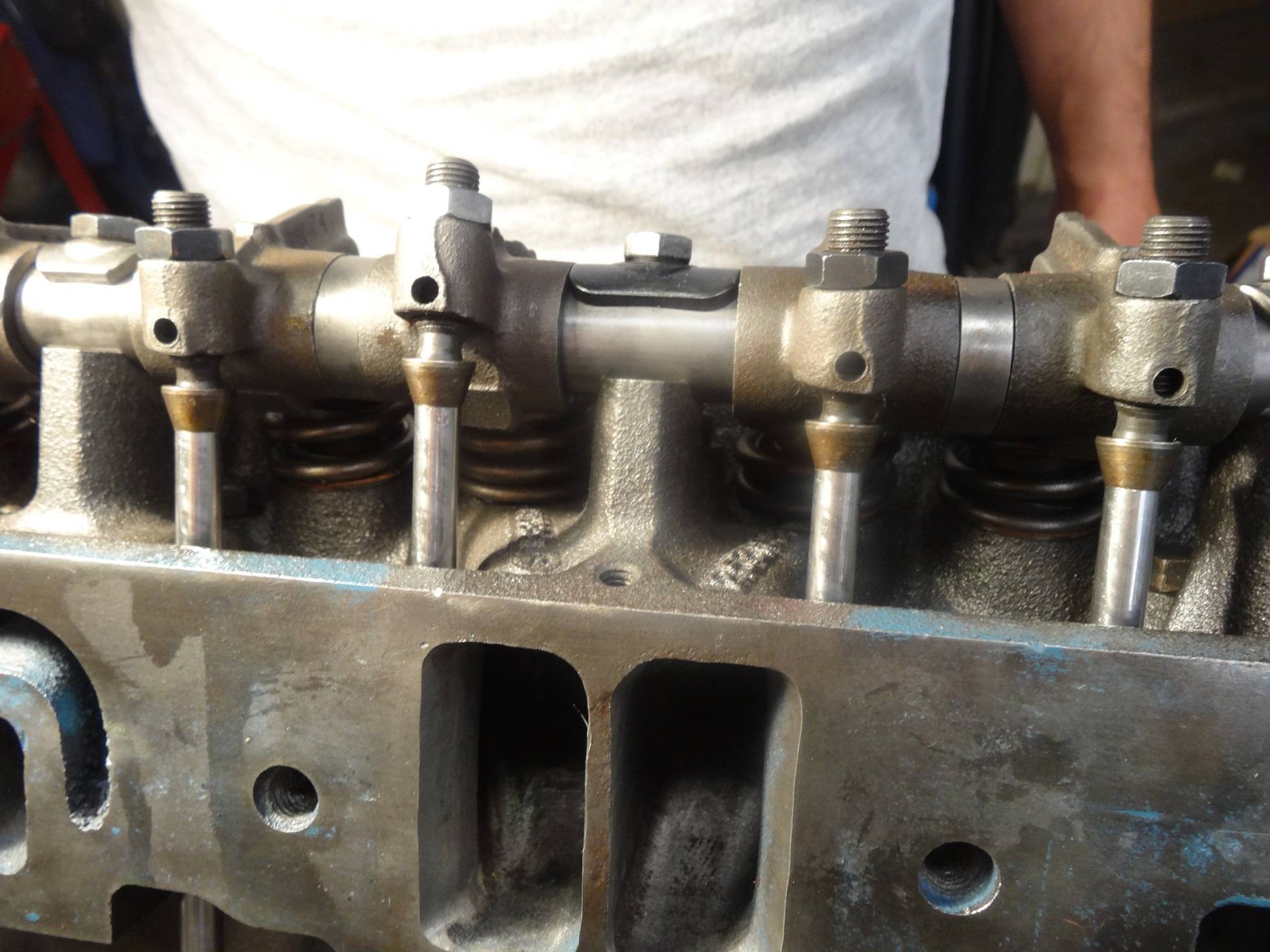

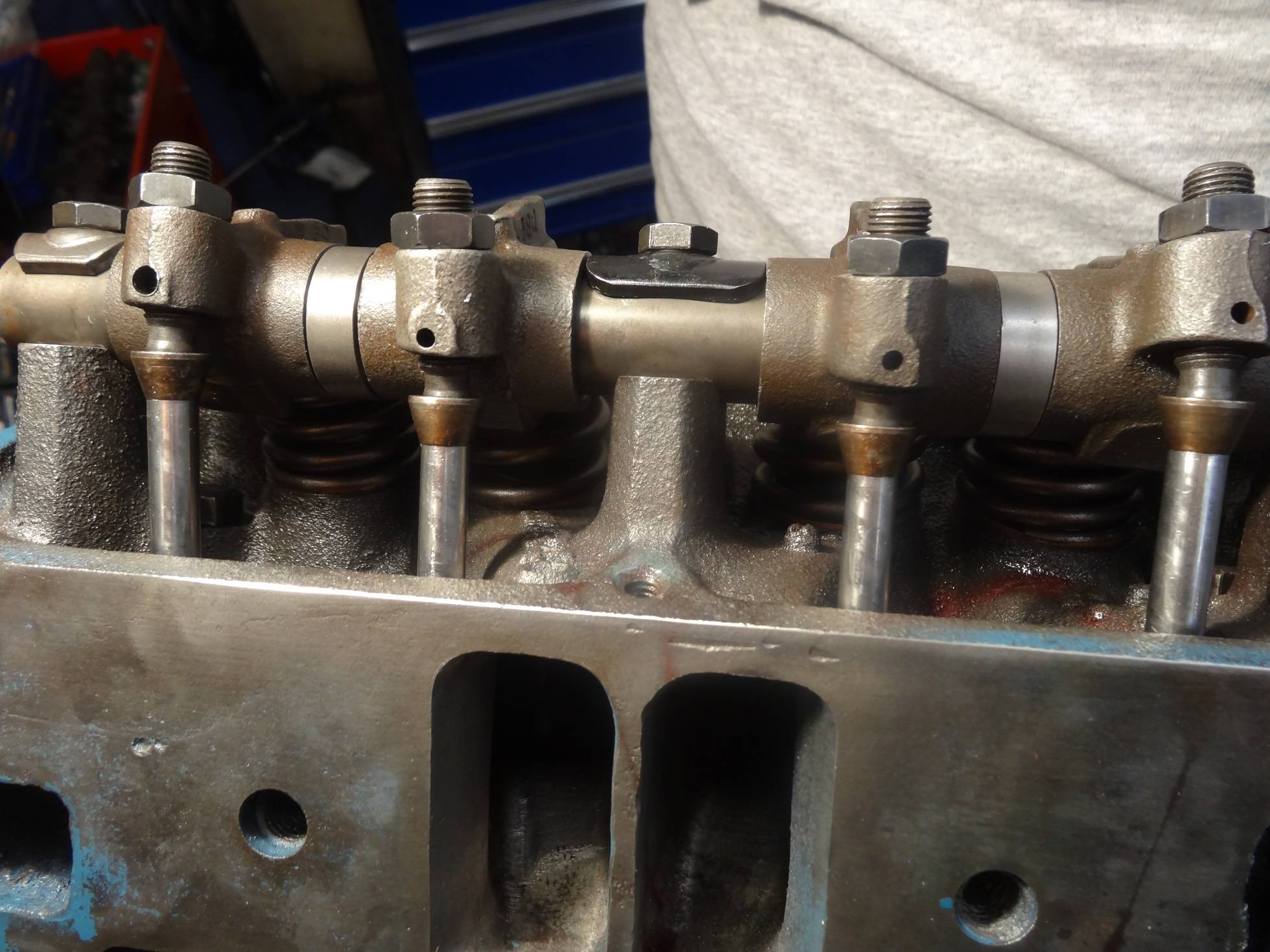

We installed them today and have about an average of 1 1/2 threads below the rocker arm with the Comp Cams replacement lock studs/nuts for the rockers:

We did get a measuring push rod and measured each 5 times to get a good average length. We ended up needing 7.058" from cup to ball.

We ordered a set, and they came. We measured them to be average of 7.064" +/- .005" from cup to ball and installed them....

We installed them today and have about an average of 1 1/2 threads below the rocker arm with the Comp Cams replacement lock studs/nuts for the rockers:

Here are a few good related threads for reference:

Here's some good info in this thread on using the 273 rocker arm and adjustable nuts:

273 adj rocker stud and lock nut?? Where?

Here's a thread with all the info for push rods using 273 adjustable rocker arms with a hydraulic cam:

273 stock push rod length?

Here's some good info in this thread on using the 273 rocker arm and adjustable nuts:

273 adj rocker stud and lock nut?? Where?

Here's a thread with all the info for push rods using 273 adjustable rocker arms with a hydraulic cam:

273 stock push rod length?

daves66valiant

68 Dart 340/727:66 Signet Vert 340/5spd: 68 D100

The SUM-G6420-16 are a tad long for the stock adjusters. I found only 3/4 to 1 thread showing. No way Jose with the locking studs.

Based on everything I’ve read. I found some from summit that might work for the Crane Locking adjusters.

Melling Pushrods MPR-157

Overall length 7.234 in

0.015” difference in length from what krazycuda posted. I imagine it should be fine for my 340 setup.

Will report back in a few days

Based on everything I’ve read. I found some from summit that might work for the Crane Locking adjusters.

Melling Pushrods MPR-157

Overall length 7.234 in

0.015” difference in length from what krazycuda posted. I imagine it should be fine for my 340 setup.

Will report back in a few days

Wyrmrider

Well-Known Member

50 year old iron

heads or block milled

lifter vendor have consolidated

just start over with an adjustable pushrod as Rat Rod has stated

do the mid lift method with the adjuster up as far as possible - you may have changed the lift, different base circle, milled this or that

mechanically you measure from the center of the balls but who does that?

sending the adjusted pushrod to the mfg gets you the correct ones

or it's on you to figure out how the vendors spec their pushrods - over all length, bottom of the cup etc

btw use AMC/Magnum lifters and oil the rocker adjuster balls or cups in the stock rockers through the pushrods

and if you have roller tip rockers move the shafts up and over

Crane used to sell offset shafts- must be a reason

heads or block milled

lifter vendor have consolidated

just start over with an adjustable pushrod as Rat Rod has stated

do the mid lift method with the adjuster up as far as possible - you may have changed the lift, different base circle, milled this or that

mechanically you measure from the center of the balls but who does that?

sending the adjusted pushrod to the mfg gets you the correct ones

or it's on you to figure out how the vendors spec their pushrods - over all length, bottom of the cup etc

btw use AMC/Magnum lifters and oil the rocker adjuster balls or cups in the stock rockers through the pushrods

and if you have roller tip rockers move the shafts up and over

Crane used to sell offset shafts- must be a reason

pishta

I know I'm right....

For T/A's.....Get a pushrod from a slant and a chop saw. Grind the ball end out and reduce the OD of the slip joint so it will just stay in the tube. Start trimming the open ended pushrod until you get the right length.I sure hope so since Mopar made a pile of um.

Last edited:

Bighead440

Well-Known Member

Yeah you are right. I don't know what the hell I was thinkin. lol

The rare 340 "Six-Pack" had said pushrods (adjustable rockers/hydraulic lifters) from the factory.

ir3333

Well-Known Member

Here's the latest update:

We did get a measuring push rod and measured each 5 times to get a good average length. We ended up needing 7.058" from cup to ball.

We ordered a set, and they came. We measured them to be average of 7.064" +/- .005" from cup to ball and installed them....

We installed them today and have about an average of 1 1/2 threads below the rocker arm with the Comp Cams replacement lock studs/nuts for the rockers:

View attachment 1714935686

are those adjustable rocker lock nut faces machined?

daves66valiant

68 Dart 340/727:66 Signet Vert 340/5spd: 68 D100

I had an adjustable pushrod tool from Hughes but can find the damn thing in my storage garage. I may still go custom to get the perfect pushrod from either smith brothers or OE.

Bought the Melling ones from Summit. Returns are easy enough with them. They have been really good to me.

Bought the Melling ones from Summit. Returns are easy enough with them. They have been really good to me.

We spot faced them on a grinder for a flatter surface...

ir3333

Well-Known Member

for those that just go with the interference fit adjusters...slant six pieces work fine!

Who did those heads, K.K.? Nice work!Here's the latest update:

We did get a measuring push rod and measured each 5 times to get a good average length. We ended up needing 7.058" from cup to ball.

We ordered a set, and they came. We measured them to be average of 7.064" +/- .005" from cup to ball and installed them....

We installed them today and have about an average of 1 1/2 threads below the rocker arm with the Comp Cams replacement lock studs/nuts for the rockers:

View attachment 1714935686

View attachment 1714935687

View attachment 1714935688

View attachment 1714935689

View attachment 1714935690

Wyrmrider

Well-Known Member

note that the adjusters shown have the long thread to ball distance

hard to get it right unless "screwed up" to match early adjusters

some say to put the cup on the adjuster and use Ball and Ball pushrods

what say you everyone?

hard to get it right unless "screwed up" to match early adjusters

some say to put the cup on the adjuster and use Ball and Ball pushrods

what say you everyone?

Who did those heads, K.K.? Nice work!

John Tret, my head guy in Dearborn, MI...

He does nice machine work...

Thanks....

-