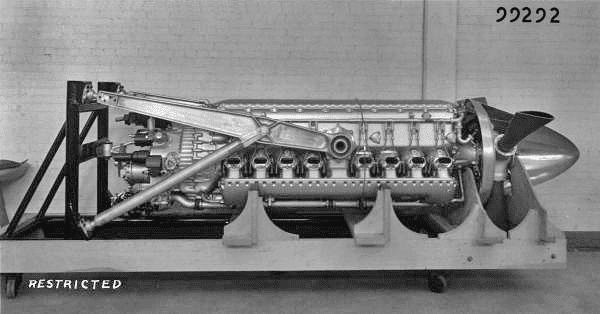

"A key step in the development of the famous Chrysler Hemi V8 was this monster: a 2500-horsepower aircraft engine designed for the U.S. armed forces in World War II.

In histories of the Chrysler Corporation (now Stellantis) and its Hemi engine program, the beast shown here is invariably included in the narrative. First proposed to the U.S. Army Air Corps in the summer of 1940, the XI-2220 is quite a remarkable engine, and its hemispherical combustion chambers aren’t the half of it".

"Carefully engineered for minimal frontal area and low aerodynamic drag, the 60-degree V16 was barely 33 inches wide—but more than 10 feet long. The layout was an inverted vee, like Germany’s Mercedes-Benz V12s of WWI. That is, as installed in the aircraft, the crankshaft was on top with the cylinders underneath. Another distinctive feature: the big Chrysler’s propeller drive and gear reduction unit were mounted not at the end but at the middle of the crankshaft, in order to control the tremendous torsional vibrations—the forces from the two halves of the engine could now stabilize rather than battle each other. Also due to the engine’s great length and weight (2430 lbs) it was supported at the middle when mounted in the aircraft. Note the massive I-beams and tubular braces that form the cantilevered engine mount".

In histories of the Chrysler Corporation (now Stellantis) and its Hemi engine program, the beast shown here is invariably included in the narrative. First proposed to the U.S. Army Air Corps in the summer of 1940, the XI-2220 is quite a remarkable engine, and its hemispherical combustion chambers aren’t the half of it".

"Carefully engineered for minimal frontal area and low aerodynamic drag, the 60-degree V16 was barely 33 inches wide—but more than 10 feet long. The layout was an inverted vee, like Germany’s Mercedes-Benz V12s of WWI. That is, as installed in the aircraft, the crankshaft was on top with the cylinders underneath. Another distinctive feature: the big Chrysler’s propeller drive and gear reduction unit were mounted not at the end but at the middle of the crankshaft, in order to control the tremendous torsional vibrations—the forces from the two halves of the engine could now stabilize rather than battle each other. Also due to the engine’s great length and weight (2430 lbs) it was supported at the middle when mounted in the aircraft. Note the massive I-beams and tubular braces that form the cantilevered engine mount".

Last edited: