tubtar

Well-Known Member

Solid roller , good rockers , 240 seat and 590 over the nose.......I have about 500 miles on the motor and don't think it's seen 8000 r.p.m.

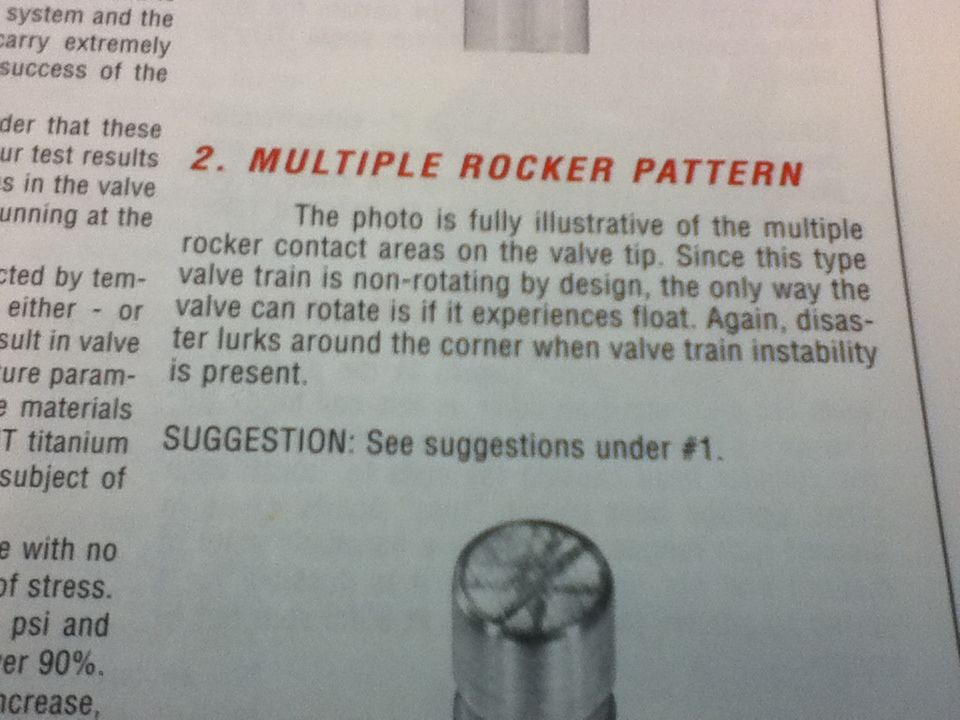

I am putting it back together after removing the rockers over the winter , and noticed scrub marks that tend to indicate that the valves have not rotated as it has been running.

This is my first go round with a solid roller , so I don't know if I have a problem or not.

15 of the 16 valves appear to be fairly stationary and the one on the right in this pic shows that it has spun around some.

Thanks for your help.

I am putting it back together after removing the rockers over the winter , and noticed scrub marks that tend to indicate that the valves have not rotated as it has been running.

This is my first go round with a solid roller , so I don't know if I have a problem or not.

15 of the 16 valves appear to be fairly stationary and the one on the right in this pic shows that it has spun around some.

Thanks for your help.