You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Small Block Head Flow Chart

- Thread starter TurboGLH

- Start date

-

my question for the experts....does the Barometer have any effect on the CFM ?.....

Yes if you have a pilot type of flowbench with fluid manometers. That why I built the bench I did. With a fluid manometer you have to do a weather calibration every time you flow a head and guys don’t do it. They will usually just plug a standard number in there.

MOPAROFFICIAL

If it has tits, it's a liabilititty.

This.Yes if you have a pilot type of flowbench with fluid manometers. That why I built the bench I did. With a fluid manometer you have to do a weather calibration every time you flow a head and guys don’t do it. They will usually just plug a standard number in there.

For the same reason, I use a digital manometer/processor..it was about 600 bucks, everything is corrected.

PRH

Well-Known Member

Yes if you have a pilot type of flowbench with fluid manometers. That why I built the bench I did. With a fluid manometer you have to do a weather calibration every time you flow a head and guys don’t do it. They will usually just plug a standard number in there.

The key here is.....”pitot style”.

Not all benches are this style.

Neither of the benches I’ve had are that style.

Both of mine are the orifice plate style(like a SuperFlow SF-600), which compare the flow through the head to an orifice of a known flow value.

(If the orifice is 300cfm, and the inclined manometer reads 50%, you’re flowing 150cfm)

Since both sides of the orifice are operating with the same baro pressure...... it’s not supposed to impact the results.

For example, on a high air pressure day, the pressure is trying to push the air through the head...... but that same high pressure is working against the air as its trying get out of the bench.

The rise or fall in pressure helps one side of the orifice...... and impedes the other side.

My old SF-110, that I bought new and had for 14 years and did countless tests on.......whenever I used the calibration plate, and let the temperature differential between the two sides of the pumps stabilize at about 30*....... the reading on the manometer was always the same.

The pitot style bench isn’t comparing to anything, it’s trying gauge what the actual flow of the air is through the flow tube.

And, in order to know what the flow is...... you need to know what the air density is.

So, the weather matters.

I bought this bench new in 2007.

Last edited:

Iron #974

11/32 nailhead w/undercut stem 1.94/1.60 valves blended in, minor guide trimming.

--------Int--------exh

.100..64.............

.200..128.....103

.300..191.....146

.400..229.....169

.500..241.5..180

.550..241.....192

.600..240......199

Very similar to what my 302's flow but with a Ferrea 1.900 from memory. Can you remember what your port volume ended up at?

B3422w5

Well-Known Member

Interesting observation on W5 heads.

I had the first set Ryan ever did. Supposedly Brett did a single intake and exhaust, and Ryan “ copied” them.

On his site he claimed 330 ish cfm max.

Best Machine flowed them, along with another well known Mopar head guru i have a ton of respect for.

Those heads barely reached 300 on both their benches.

That said, those heads went on to run right at 140 mph in a 3220 pound race weight A body, until they ultimately turned into sprinklers. That on 002/003 leafs. So not some trick chassis car

You can do the math, thats a pretty solid 700 ish horsepower.

Convinced me flow benches aren't everything. But good for comparisons.

I was astonished by the relatively “ low” flow numbers but the numbers they put up at the track.

Once those heads “ went away” they were swapped for Modern cnc W5 heads, no other changes

ET looked 25 ish horse less with the CNC units over hand ported ones

I had the first set Ryan ever did. Supposedly Brett did a single intake and exhaust, and Ryan “ copied” them.

On his site he claimed 330 ish cfm max.

Best Machine flowed them, along with another well known Mopar head guru i have a ton of respect for.

Those heads barely reached 300 on both their benches.

That said, those heads went on to run right at 140 mph in a 3220 pound race weight A body, until they ultimately turned into sprinklers. That on 002/003 leafs. So not some trick chassis car

You can do the math, thats a pretty solid 700 ish horsepower.

Convinced me flow benches aren't everything. But good for comparisons.

I was astonished by the relatively “ low” flow numbers but the numbers they put up at the track.

Once those heads “ went away” they were swapped for Modern cnc W5 heads, no other changes

ET looked 25 ish horse less with the CNC units over hand ported ones

MOPAROFFICIAL

If it has tits, it's a liabilititty.

Very similar to what my 302's flow but with a Ferrea 1.900 from memory. Can you remember what your port volume ended up at?

I really don't, but have it written down somewhere... 170'ish sounds about right, they are 160 as cast with 1.88 intake valves

Just bowl, short turn , kink work.

If you can find head with good tall exhaust short turns...they're valuable. You can get a pair from the same stock motor and and up with one that does great, better than average and the other struggle... ported even. Got a guys heads that one is great on the exhaust while the other is 25cfm behind...put clay in the low dead side, 1/4 with is all...and then it does 195 by .400...

Sometimes I wonder if when they design these heads and cast...that if somebody then put them on the bench and said oh no this exhaust Port works way too good... let's go ahead and just carve this section out here and that'll "fix" it. All they had to do was raise that side.Maybe they had the foresight to bolster their performance head sales that way..? "they have to buy a head"

PRH

Well-Known Member

SM Head...... ootb vs reworked valve seats(with very small back cut on both valves) and minor bowl blend......

4.00 bore, 28” test pressure, no tube on exhaust.

A-ootb

B-reworked

Intake-

Lift———A/B

.100— 61/65

.200— 120/126

.300— 177/180

.400— 221/230

.450— 231/246

.500— 240/256

.550— 250/267

.600— 250/262

.650— 251/261

.700— 253/261

Exhaust-

Lift———A/B

.100— 49/50

.200— 97/101

.300— 134/139

.400— 154/169

.450— 160/174

.500— 164/178

.550— 166/179

.600— 168/180

.650— 168/181

.700— 168/182

It’s a decent gain considering it’s maybe a 1cc increase in runner volume.

4.00 bore, 28” test pressure, no tube on exhaust.

A-ootb

B-reworked

Intake-

Lift———A/B

.100— 61/65

.200— 120/126

.300— 177/180

.400— 221/230

.450— 231/246

.500— 240/256

.550— 250/267

.600— 250/262

.650— 251/261

.700— 253/261

Exhaust-

Lift———A/B

.100— 49/50

.200— 97/101

.300— 134/139

.400— 154/169

.450— 160/174

.500— 164/178

.550— 166/179

.600— 168/180

.650— 168/181

.700— 168/182

It’s a decent gain considering it’s maybe a 1cc increase in runner volume.

Last edited:

Awesome. Thanks for sharing. Kim

512Stroker

We are all here because we are not all there.

NiceSM Head...... ootb vs reworked valve seats(with very small back cut on both valves) and minor bowl blend......

4.00 bore, 28” test pressure, no tube on exhaust.

A-ootb

B-reworked

Intake-

Lift———A/B

.100— 61/65

.200— 120/126

.300— 177/180

.400— 221/230

.450— 231/246

.500— 240/256

.550— 250/267

.600— 250/262

.650— 251/261

.700— 253/261

Exhaust-

Lift———A/B

.100— 49/50

.200— 97/101

.300— 134/139

.400— 154/169

.450— 160/174

.500— 164/178

.550— 166/179

.600— 168/180

.650— 168/181

.700— 168/182

It’s a decent gain considering it’s maybe a 1cc increase in runner volume.

View attachment 1715570238

View attachment 1715570242

View attachment 1715570243

How amazing the cfm numbers go flat after .550

Pretty much tells you what cam to use.

I like it, thanks for posting

Last edited:

Nice

I amazing the cfm numbers go flat after .550

Pretty much tells you what cam to use.

I like it, thanks for posting

Begging for shortside area.

The pitot style bench isn’t comparing to anything, it’s trying gauge what the actual flow of the air is through the flow tube.

And, in order to know what the flow is...... you need to know what the air density is.

So, the weather matters.

...and it does matter! I have a redundant system of verifying Baro and Humidity, and I have to keep tabs on conditions as I go.

Selling that 110 probably felt pretty good, huh. What a pain to use!

gotta warm it up all the time... like an ex I used to have..

PRH

Well-Known Member

Actually, the SF-110 was very user friendly IMO.

I did countless tests on that thing.

The thing I found with a small bench not being able to generate high pressures with the big heads was not so much that it couldn’t get the head to go turbulent if the shape was wrong...... it was that it didn’t reveal the gains that you could get out of increased “area”.

Shape was everything......area, not so much.

I really struggled with keeping the Indy 440-1 heads from getting unhappy at high lifts.

When I got the bigger bench and could pull the full 28”....... that problem, for the most part, just went away.

I had both benches for a while.

In a nutshell, on the new bench(compared to the old)...... small heads showed lower numbers, big heads showed higher numbers.

But..... that’s all drifting away from the thread topic.

I did countless tests on that thing.

The thing I found with a small bench not being able to generate high pressures with the big heads was not so much that it couldn’t get the head to go turbulent if the shape was wrong...... it was that it didn’t reveal the gains that you could get out of increased “area”.

Shape was everything......area, not so much.

I really struggled with keeping the Indy 440-1 heads from getting unhappy at high lifts.

When I got the bigger bench and could pull the full 28”....... that problem, for the most part, just went away.

I had both benches for a while.

In a nutshell, on the new bench(compared to the old)...... small heads showed lower numbers, big heads showed higher numbers.

But..... that’s all drifting away from the thread topic.

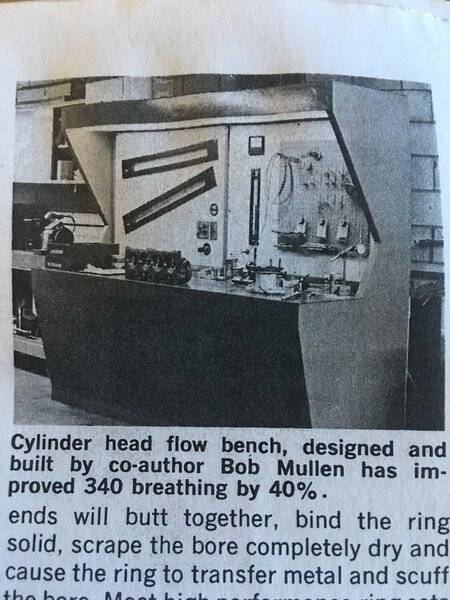

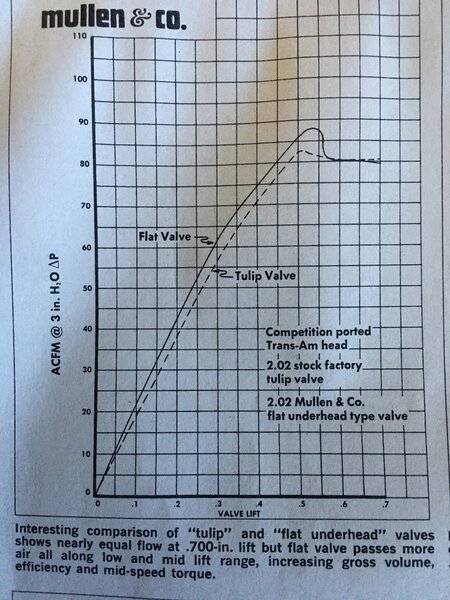

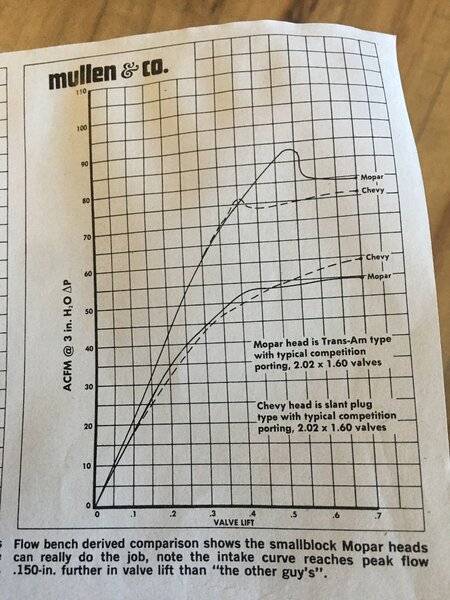

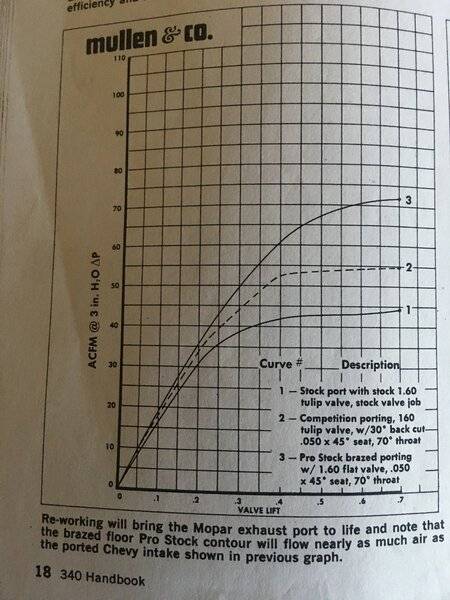

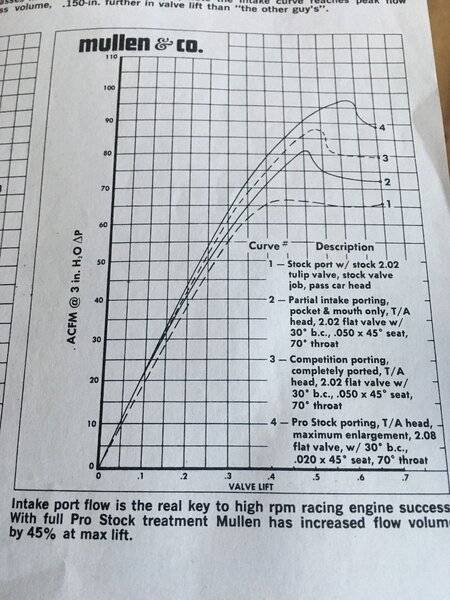

Mullen head flow modifications and results on T/A 340 heads, taken @ 3.0 inches H2O.

Actually, the SF-110 was very user friendly IMO.

I did countless tests on that thing.

The thing I found with a small bench not being able to generate high pressures with the big heads was not so much that it couldn’t get the head to go turbulent if the shape was wrong...... it was that it didn’t reveal the gains that you could get out of increased “area”.

Shape was everything......area, not so much.

I really struggled with keeping the Indy 440-1 heads from getting unhappy at high lifts.

When I got the bigger bench and could pull the full 28”....... that problem, for the most part, just went away.

I had both benches for a while.

In a nutshell, on the new bench(compared to the old)...... small heads showed lower numbers, big heads showed higher numbers.

But..... that’s all drifting away from the thread topic.

That is what i am so looking forward with my new bench. Turning the bench down to 10", for above .300 lift, was surely hiding some turbulence.

Looking forward using my flow bench. but with the move into a new home and state, building a shop out back, and my new job........I think it will be another year before i can warm, do a final calibration, and get at it again.

Mullen head flow modifications and results on T/A 340 heads, taken @ 3.0 inches H2O.

View attachment 1715637376

View attachment 1715637377

View attachment 1715637379

View attachment 1715637380

View attachment 1715637381

I like reading old stuff like that.

3 inches of vac and 87 CFM

What i found the most interesting was that the cfm laying over at .500" and .600", with the larger valve.

Even though it may have hidden some unseen hidden turbulence, the "air back up" was at the same lift.........Interesting.

They are out of cores correct ?

LA that is ?

MOPAROFFICIAL

If it has tits, it's a liabilititty.

Yes.

MOPAROFFICIAL

If it has tits, it's a liabilititty.

I flowed one of the SM al ootb intake ports

@28, 1"clay engine pro 2003.100 valve

.100-61

.200-126.8

.300-183.2

.400-226

.500-240.7

.600-247

I moved to the port next to it and did like everyone else did and touched the valve job 60,45,30...the 45 really needs to be set lower to get a good 30. I plan on doing that later today and retesting...but for now.

.100 61.9

.200-132

.300-186

.400-228

.500-247

.600-253

Then i just lightly blended the ledge @ the short turn only. "'#'s on right are with the vj lowered wider 60 , narrower 45 and wider 30 & unshroud chamber."

.100-62.3.....63

.200-132......133.7

.300-188......192

.400-232......236

.500-255......255-261 turbulence.

.600-253- it hiccups & recovers

.630-263

Only took 1 pic last nite, you can see i used a 2 1/4 stone by the minor unshroud at the chamber. ill take one of the rest and post later.

Then i added a 75 below the 60 to and then 'lengthened' the straight side of the short turn back and lipped it a hair just to the center of the ssr peak.

.100 64

.200 134

.300 192

.400 237--lengthened the ssr more=244

.500 260 cfm

.550 264

.600 255

I had to blend the head bolt bulge and the push rod pinch is opened to .950

If i calm the air speed at the window, it goes 268cfm by .550/.600

@28, 1"clay engine pro 2003.100 valve

.100-61

.200-126.8

.300-183.2

.400-226

.500-240.7

.600-247

I moved to the port next to it and did like everyone else did and touched the valve job 60,45,30...the 45 really needs to be set lower to get a good 30. I plan on doing that later today and retesting...but for now.

.100 61.9

.200-132

.300-186

.400-228

.500-247

.600-253

Then i just lightly blended the ledge @ the short turn only. "'#'s on right are with the vj lowered wider 60 , narrower 45 and wider 30 & unshroud chamber."

.100-62.3.....63

.200-132......133.7

.300-188......192

.400-232......236

.500-255......255-261 turbulence.

.600-253- it hiccups & recovers

.630-263

Only took 1 pic last nite, you can see i used a 2 1/4 stone by the minor unshroud at the chamber. ill take one of the rest and post later.

Then i added a 75 below the 60 to and then 'lengthened' the straight side of the short turn back and lipped it a hair just to the center of the ssr peak.

.100 64

.200 134

.300 192

.400 237--lengthened the ssr more=244

.500 260 cfm

.550 264

.600 255

I had to blend the head bolt bulge and the push rod pinch is opened to .950

If i calm the air speed at the window, it goes 268cfm by .550/.600

Last edited:

Deweywinger&howe

Well-Known Member

Trick flows?

Trick flows?

Trick flows are on the bottom of the chart, but they're like the promaxx heads, numbers are from the mfg. Since they have different ports and raised rockers positions they're not under the Edelbrock clone section.

Last edited:

Deweywinger&howe

Well-Known Member

ThanksTrick flows are on the bottom of the chart, but they're like the promaxx heads, numbers are from them mfg. Since they have different ports and raised rockers positions they're not under the Edelbrock clone section.

-

Similar threads

- Replies

- 16

- Views

- 8K

- Replies

- 22

- Views

- 21K