I rebuilt my 318 like 15 years ago and have put on 8k miles in that time. I replaced the alternator at the same time and recently the bearing went out on me. Seeing how alternators are relatively cheap I was just going to replace it. But when I started reading it looks like there is much against the newer (I assume mine is one, Oreilly) square backs but I don’t really understand the issue? Mine has always done well to keep a charge and I’ve ran it at night. Just wondering what I’m missing out on before I make a bad purchase.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Squareback vs round back alternator?

- Thread starter jrc4y4

- Start date

-

The square back is by far the better unit.

67Dart273

Well-Known Member

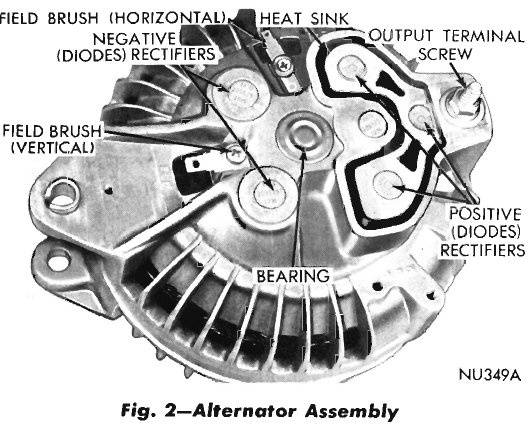

Square back is a better design, and some amp ratings charge better at low rpm. 45amp I think. Something that seems to be prevalent with rebuilders is MISSING OR IMPROPERLY installed brush hardware/ insulators. BEFORE you wire it up, check between the two brushes (field terminals) which should show a low value of resistance. Then check each field terminal to the case and it should be "open" (infinity) resistance

What do you have now?

Do you want to keep the oem look?

I agree alternators are cheap, but round back alternators are few and far between ( I'm going through this right now)

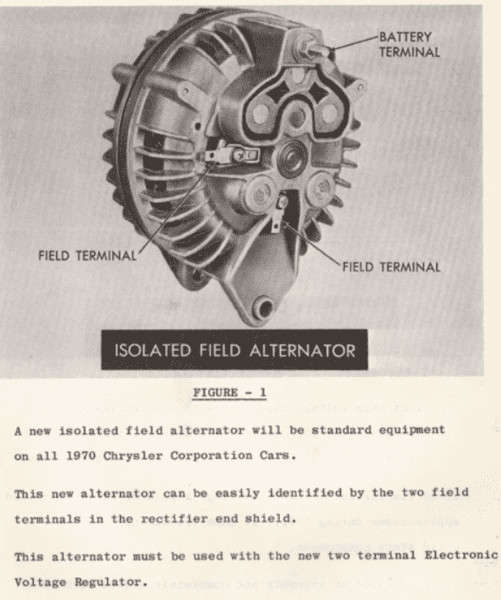

Alternators 101...

Mopar had 4 alternators

Round back single field wire

Round back dual field wire

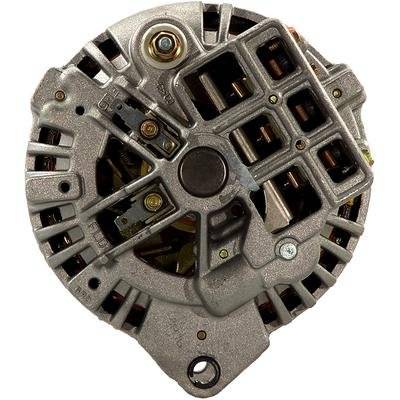

Square back wired as a single field wire (note green wire to one field wire)

This is also a square back wired as a one field wire (one of the terminals is internally grounded, note the tab is clipped off, this is what you will get from the parts store if you buy a "round back" alternator 99% of the time)

Square back dual field wire.

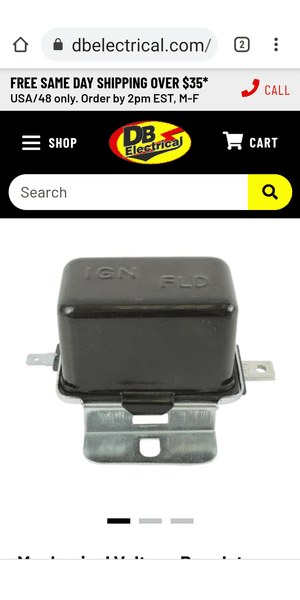

If you have the old style square voltage regulator

you need a single field wire alt regardless of round or square

If you have the newer rectangular VR with triangular shaped connector

you need the dual field wire alternator regardless of round or square

The square backs have a higher output than round BUT if you have oem electronics on your car there is no need for a higher output alt. Infact it can de detrimental.

Alternators are relitivily easy to rebuild and parts are readily available.

A press is the most complicated part of the process.

The diameter of the pulley is a main contributer of poor charging at idle.

I recently posted "diameter, diameter, diameter, alternator pulley" showing the ammeter bouncing with a 2.75 dia pulley vs a 2.5 dia pulley Diameter, diameter, diameter, alternator pulleys

Do you want to keep the oem look?

I agree alternators are cheap, but round back alternators are few and far between ( I'm going through this right now)

Alternators 101...

Mopar had 4 alternators

Round back single field wire

Round back dual field wire

Square back wired as a single field wire (note green wire to one field wire)

This is also a square back wired as a one field wire (one of the terminals is internally grounded, note the tab is clipped off, this is what you will get from the parts store if you buy a "round back" alternator 99% of the time)

Square back dual field wire.

If you have the old style square voltage regulator

you need a single field wire alt regardless of round or square

If you have the newer rectangular VR with triangular shaped connector

you need the dual field wire alternator regardless of round or square

The square backs have a higher output than round BUT if you have oem electronics on your car there is no need for a higher output alt. Infact it can de detrimental.

Alternators are relitivily easy to rebuild and parts are readily available.

A press is the most complicated part of the process.

The diameter of the pulley is a main contributer of poor charging at idle.

I recently posted "diameter, diameter, diameter, alternator pulley" showing the ammeter bouncing with a 2.75 dia pulley vs a 2.5 dia pulley Diameter, diameter, diameter, alternator pulleys

Last edited:

pishta

I know I'm right....

what regulator are you running? round back single field used the old "in and out" regulator. The round back dual field only came in 2 years (70-71) then it went to the common dual field squareback. The dual field needs the electronic voltage regulator, or can be grounded on one of the fields to use the old style regulator.

67Dart273

Well-Known Member

If you have the old style square voltage regulator you need a single field wire alt regardless of round or square

Not entirely (stated) correct. you can ground either field terminal on either a round or square "isolated field" and use them with the old regulator. I'm sure you know that LOL

Re read what I wrote you and I are saying the same thing. I outlined the 4 mopar alts 2 round 2 square. One round and 1 square are 1 wire field.Not entirely (stated) correct. you can ground either field terminal on either a round or square "isolated field" and use them with the old regulator. I'm sure you know that LOL

(Yes the square is a 2 field wire "isolated field" with one of the field wires grounded)

Great info- even for us people who had them when all you got was a round back from the dealer. Ha!

Chrysler never made a grounded field squareback.

You can convert any isolated field into a grounded field.

Now what the hell was the original question?

Should you roll the dice with a parts store replacement or replace the bearing?

Yes

You can convert any isolated field into a grounded field.

Now what the hell was the original question?

Should you roll the dice with a parts store replacement or replace the bearing?

Yes

From what I have seen the parts store alternators are all basically the same square backs. They just ground one of the brushes for the 69 back application as mentioned above.

Turns out I have a dual field square back with triangular plug voltage regulator. I’ve ran it for 8k miles with no issues (except a bearing) and I’ll get one to replace it like it. Thanks guys! I learned a lot about different types of alternators from you guys. Who knew there were so many variations?

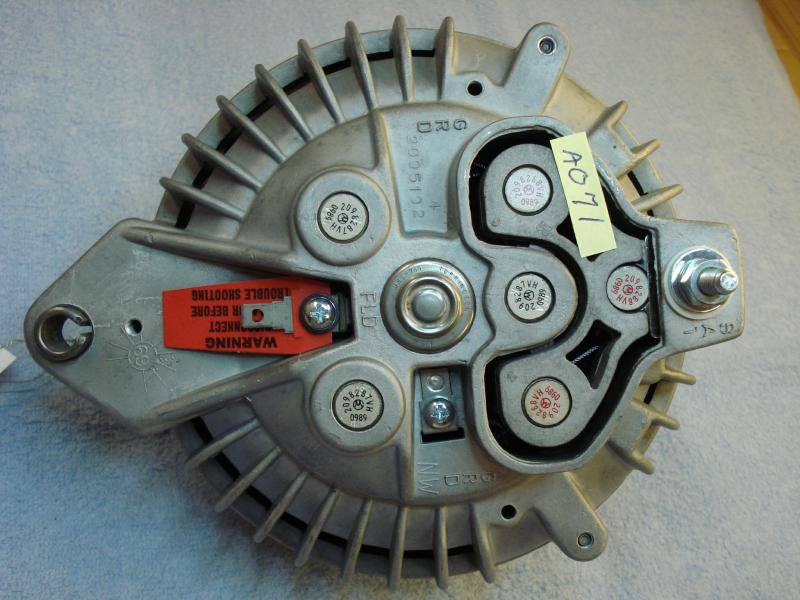

Thats one messed up alternator. Lucky it made it that far.

Next one you buy, try to get a regular squareback, not a revised one like you've got there.

The rear bearing should be flush or a little proud of the casting.

The output stud MUST have an insulator and MUST not be loose.

Identifying Chrysler Alternators (1960-1976)

Next one you buy, try to get a regular squareback, not a revised one like you've got there.

The rear bearing should be flush or a little proud of the casting.

The output stud MUST have an insulator and MUST not be loose.

Identifying Chrysler Alternators (1960-1976)

Thats one messed up alternator. Lucky it made it that far.

Next one you buy, try to get a regular squareback, not a revised one like you've got there.

The rear bearing should be flush or a little proud of the casting.

The output stud MUST have an insulator and MUST not be loose.

Identifying Chrysler Alternators (1960-1976)

good to know! I pulled the insulator off when I yanked it out, unsure if the new one would have one or not. I’ll check out the bearing when I pick up the new one this week. Thank you.

CLBER

Member

Hello from Berlin, Germany! My name is Christian and I'm a mechanic usually working on European cars.

Just a helping a friend with repairs on his Plymouth Valiant V-200, L6, 170cid from 1960.

We're facing some issues with the alternator / regulator and we hope you can help us out. We're thinking about replacing alternator and regulator, preferably an electronic one if possible. Could you help us out which would be the right parts? We guess alternator and regulator don't match.

The voltage is fluctuating by checking at the Batterie +. Voltage went up till 18 Volts, so I checked the regulator air gap btw the armature and the magnet core at the hanger side which was found within specs and I bent the spring tension up because the voltage was found to be to high. Now its withing 13 and about 15 Volts but fluctuating very much, a bit less with all consumers on.

Regards, Christian.

Just a helping a friend with repairs on his Plymouth Valiant V-200, L6, 170cid from 1960.

We're facing some issues with the alternator / regulator and we hope you can help us out. We're thinking about replacing alternator and regulator, preferably an electronic one if possible. Could you help us out which would be the right parts? We guess alternator and regulator don't match.

The voltage is fluctuating by checking at the Batterie +. Voltage went up till 18 Volts, so I checked the regulator air gap btw the armature and the magnet core at the hanger side which was found within specs and I bent the spring tension up because the voltage was found to be to high. Now its withing 13 and about 15 Volts but fluctuating very much, a bit less with all consumers on.

Regards, Christian.

Christian.

I suggest looking through this thread first.

Identifying Chrysler Alternators (1960-1976)

From appearences your regulator and alternator match.

It will be easier for you to diagnose once you understand the functional differences.

In the UK and US the circuit arrangements are called different things. In Belrlin maybe something else?

Basically the difference is whether the field strength is controlled by switching the positive feed, or by the negative connection.

Now (2022) you can exchange that mechanical regulator for a positive controlling transistorized version. However I do not know if that will resolve the problem.

Here's one sold by FBO through E-bay. I've been using it, but not long enough to say whether it is any more durable than others.

I suggest looking through this thread first.

Identifying Chrysler Alternators (1960-1976)

From appearences your regulator and alternator match.

It will be easier for you to diagnose once you understand the functional differences.

In the UK and US the circuit arrangements are called different things. In Belrlin maybe something else?

Basically the difference is whether the field strength is controlled by switching the positive feed, or by the negative connection.

Now (2022) you can exchange that mechanical regulator for a positive controlling transistorized version. However I do not know if that will resolve the problem.

Here's one sold by FBO through E-bay. I've been using it, but not long enough to say whether it is any more durable than others.

Last edited:

Ron816

Mopar forever

I went with a powermaster round back for my 68 GTS

I'm going to make two guesses about the cause:

One possibility is that only two legs of the regulator are working. This might result in a more on/off condition.

There is a 1966 Chrysler Master Technicians booklet that goes into detail about the regulator. Page 12 in particular about voltage regulation.

Find that here in html.

Alternators and Regulators (Session 228) from the 1966 Master Technician's Service Conference

Master Technician Service Conference Index - Chrysler's Training for Mechanics

or here in pdf

Browse MTSC by Model Year – 1966 – MyMopar

One possibility is that only two legs of the regulator are working. This might result in a more on/off condition.

There is a 1966 Chrysler Master Technicians booklet that goes into detail about the regulator. Page 12 in particular about voltage regulation.

Find that here in html.

Alternators and Regulators (Session 228) from the 1966 Master Technician's Service Conference

Master Technician Service Conference Index - Chrysler's Training for Mechanics

or here in pdf

Browse MTSC by Model Year – 1966 – MyMopar

Last edited:

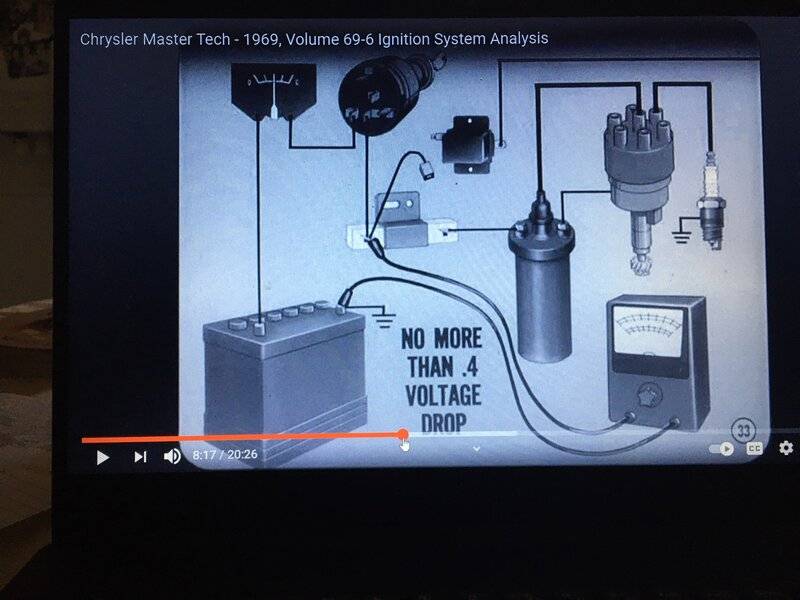

Second possible cause is in the wiring.

We see some modifications including that relay.

A relay can help work around some resistance in the run circuit. But there still can be power feed resistance problems, and with changes in load, there will be voltage drop with increased current.

The regulator will respond in an attempt to control the voltage it senses.

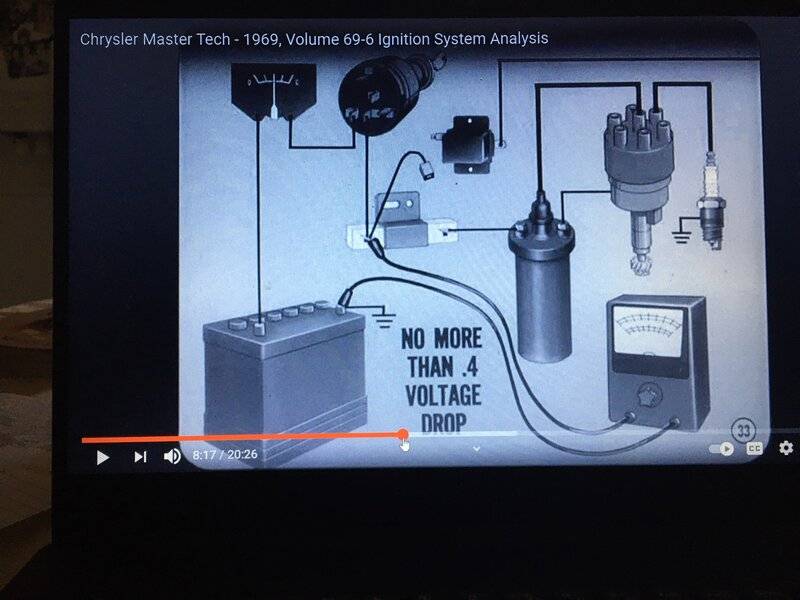

In this 1969 check, Chrysler wanted less than 0.4 Volt between the power sources (battery in this image) and the ignition and field.

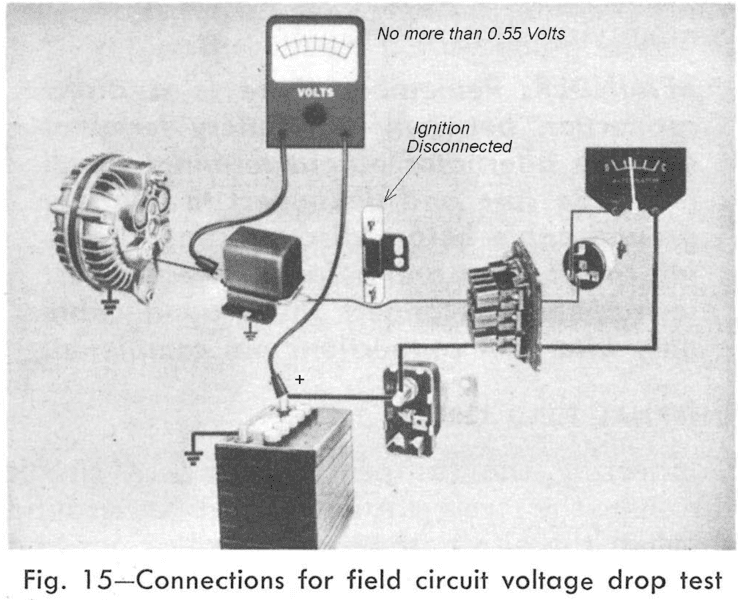

Note the field is disconnected in this check. Later there's a check with it connected. That should be less than .55 Volts difference between the battery and the regulator terminal.

Because the problem in this case is voltage regulation, it would be best to repeat the voltage drop measurement between the alternator output and the regulator input/sense terminal while the engine is running.

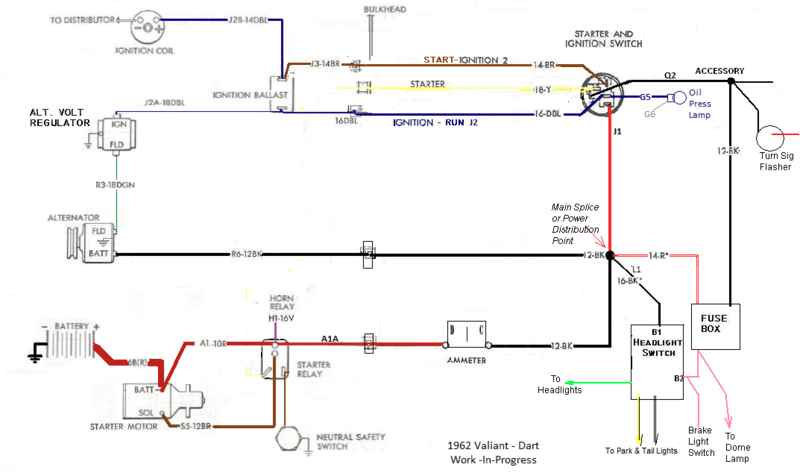

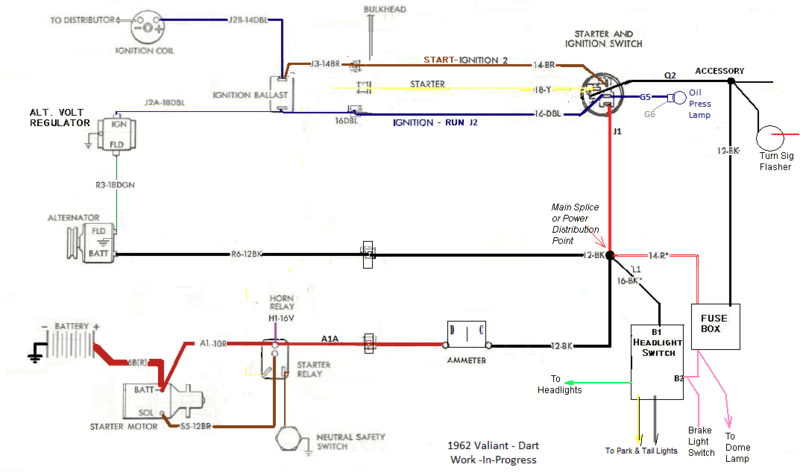

Originally the circuits looked like this.

This is a very simple arrangment.

When the alternator is generating power, current flows to the main splice through one connection.

Then to the key switch, and out to the ignition and voltage regulator.

However, if the R6 wire or connections are damaged, then there will be increasing voltage drop with increasing current flow.

Same goes for resistance or poor connections in the J1 wire, key switch, and Run wires (labelled J2).

Someone installed a relay, possibly to work around a poor connection.

We also often see accessories added to the battery. Perhaps the new fuses were added to the battery circuit. This is generally a poor location in older vehicles because power coming from the alternator does not go directly to the battery. Recharging the battery was a secondary function and a little electrical noise was not a concern.

We see some modifications including that relay.

A relay can help work around some resistance in the run circuit. But there still can be power feed resistance problems, and with changes in load, there will be voltage drop with increased current.

The regulator will respond in an attempt to control the voltage it senses.

In this 1969 check, Chrysler wanted less than 0.4 Volt between the power sources (battery in this image) and the ignition and field.

Note the field is disconnected in this check. Later there's a check with it connected. That should be less than .55 Volts difference between the battery and the regulator terminal.

Because the problem in this case is voltage regulation, it would be best to repeat the voltage drop measurement between the alternator output and the regulator input/sense terminal while the engine is running.

Originally the circuits looked like this.

This is a very simple arrangment.

When the alternator is generating power, current flows to the main splice through one connection.

Then to the key switch, and out to the ignition and voltage regulator.

However, if the R6 wire or connections are damaged, then there will be increasing voltage drop with increasing current flow.

Same goes for resistance or poor connections in the J1 wire, key switch, and Run wires (labelled J2).

Someone installed a relay, possibly to work around a poor connection.

We also often see accessories added to the battery. Perhaps the new fuses were added to the battery circuit. This is generally a poor location in older vehicles because power coming from the alternator does not go directly to the battery. Recharging the battery was a secondary function and a little electrical noise was not a concern.

Last edited:

CLBER

Member

Thank you all for your feedback and input, now we have something to digest and test.

I have found a transistorized regulator (like the one @Mattax showed) and to my surprise someone in Berlin sold it via ebay, it'll arrive very soon. But before we install it we need to draw a clean wiring diagram and eventually modify the wiring because it's all messed up. The original wiring is very simple but the past modifications (e.g. additional fuses, relais etc.) makes it more difficult to determin the fault(s). I'm gonna keep you updated and sure we have more questions to post soon.

Thanks again!

Christian

I have found a transistorized regulator (like the one @Mattax showed) and to my surprise someone in Berlin sold it via ebay, it'll arrive very soon. But before we install it we need to draw a clean wiring diagram and eventually modify the wiring because it's all messed up. The original wiring is very simple but the past modifications (e.g. additional fuses, relais etc.) makes it more difficult to determin the fault(s). I'm gonna keep you updated and sure we have more questions to post soon.

Thanks again!

Christian

I'm going to throw this out there. Maybe it is just fine and functioning as expected?

If you raise the engine RPM does the fluctuation level out?

Rebuilders are notorious for putting a 70mm dia or 76mm dia pulley on alternators that should have a 63.5mm dia pulley. The seemingly small dia change makes a huge difference in alternator shaft speed and the output at 1000 rpm shaft speed vs 1500 or 2000 rpm shaft speed can be the difference between charging and not charging.

Diameter, diameter, diameter, alternator pulleys

You mentioned with more accessories turned on it levels out.

I agree with Mattax. Get familiar with the workings of the old stuff before you attempt to make changes.

The master tech videos are really good at explaining how things work.

Mymopar.com has a lot of them

Don't get too hung up on the year and the car. Early 60s work the same as late 60s.

Welcome aboard and good luck to you.

If you raise the engine RPM does the fluctuation level out?

Rebuilders are notorious for putting a 70mm dia or 76mm dia pulley on alternators that should have a 63.5mm dia pulley. The seemingly small dia change makes a huge difference in alternator shaft speed and the output at 1000 rpm shaft speed vs 1500 or 2000 rpm shaft speed can be the difference between charging and not charging.

Diameter, diameter, diameter, alternator pulleys

You mentioned with more accessories turned on it levels out.

I agree with Mattax. Get familiar with the workings of the old stuff before you attempt to make changes.

The master tech videos are really good at explaining how things work.

Mymopar.com has a lot of them

Don't get too hung up on the year and the car. Early 60s work the same as late 60s.

Welcome aboard and good luck to you.

Ha!

I just looked at this screen shot again and see that slide does not show voltage drop measurement.

Rather it shows voltage at the ignition connection. Subtracting that measurement from battery voltage will reveal voltage drop.

As described in the booklet, when using analog meters a more sensitive reading of voltage differences can be made by measuring between the battery positive and the ignition connection.

Also its taken from the ignition circuit test. The 0.4 Volts is with the field disconnected and the ignition points closed.

The following illustration is from the Field Circuit test.

In this test the engine isn't running and system voltage will be lower than the regulator's set point.

Therefore the regulator will allow maximum current through to the rotor.

When testing for voltage drop with the engine running, the test lead will have to be on the regulator's input terminal.

The other test lead should be used to measure the alternator's output voltage, and then also the voltage at the battery positive.

Be sure the battery has finished charging before measuring for voltage drop.

It looks to me like chrysler really wanted no more of 0.2 Volts lost when the alternator was running the engine and one accessory.

That's my interpretation of this 1960 test.

1960 Imperial and Chrysler Service Repair Book - Alternator Service

In it, the output is controlled by engine rpm. I'm not really thrilled with that idea.

I think it would be safer to leave the regulator connected and add a load to the system thats approximately 10 amps. For example, heater fan on medium speed, or lights on.

That's how I've been testing voltage drop. When I can I measure the amps with an inductive clamp.

I just looked at this screen shot again and see that slide does not show voltage drop measurement.

Rather it shows voltage at the ignition connection. Subtracting that measurement from battery voltage will reveal voltage drop.

As described in the booklet, when using analog meters a more sensitive reading of voltage differences can be made by measuring between the battery positive and the ignition connection.

Also its taken from the ignition circuit test. The 0.4 Volts is with the field disconnected and the ignition points closed.

The following illustration is from the Field Circuit test.

In this test the engine isn't running and system voltage will be lower than the regulator's set point.

Therefore the regulator will allow maximum current through to the rotor.

When testing for voltage drop with the engine running, the test lead will have to be on the regulator's input terminal.

The other test lead should be used to measure the alternator's output voltage, and then also the voltage at the battery positive.

Be sure the battery has finished charging before measuring for voltage drop.

It looks to me like chrysler really wanted no more of 0.2 Volts lost when the alternator was running the engine and one accessory.

That's my interpretation of this 1960 test.

1960 Imperial and Chrysler Service Repair Book - Alternator Service

In it, the output is controlled by engine rpm. I'm not really thrilled with that idea.

I think it would be safer to leave the regulator connected and add a load to the system thats approximately 10 amps. For example, heater fan on medium speed, or lights on.

That's how I've been testing voltage drop. When I can I measure the amps with an inductive clamp.

Last edited:

BillGrissom

Well-Known Member

A common problem with all combinations is that the voltage regulator (Vreg) doesn't have a solid ground. Chrysler relied on just that sheet-metal screw into the body as a ground. It never hurts to run a dedicated ground wire from the case of the Vreg to a good ground point on the car. Few people today still have the old electro-magnetic Vreg. As posted, you can buy a new electronic regulator for the older alternator (round-back) which has 1 field terminal (the other terminal grounded). Some look like the OE rectangular box, while others are a thin chrome box. That is termed "high-side switching". You can probably still buy new brushes with insulators for the alternators. Worst-case, you could switch to a later square-back alternator which has 2 field terminals. Just ground one terminal to use with the high-side Vreg, or you can use a later "low-side switch" Vreg (triangular connector) but would also have to run an IGN wire to the alternator (other terminal). The square-back alternator was used a long time, at least until 1982 (my Dodge Aries), so will likely be available for a long time.

CLBER

Member

Hello everyone, we had fun to dive into the electrical system.

First we were trying to figure out and understand the functional differences in the electrical/ignition system on the car itself and the differences to the European (except early UK) systems. It's the first time I am working on a system like that, so it takes some time to reset the mind and don't follow the usual trouble shooting path.

What we don't understand is the difference between the field strengths is controlled by switching the positive feed, or by the negative connection.

What we checked and found so far:

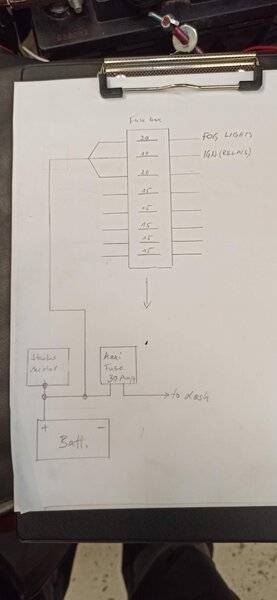

the fuse box and wires are a mess, no infos what safes what.

but we searched and the red 10 Amps is going to the control relay. It's simple 40 Amps check relay that should close and open when current is applied ...

30 goes to the 10 amp fuse

85 comes from IGN2

86 goes to ground

87 goes to alt reg IGN

initially the BAT wasn't charging and the red 10 Amp fuse was popped, I replaced it. Started the engine and another 30 Amps fuse in an extra box popped, the red 10 Amps is ok. You see that there are three cables are soldered together coming from the dash and going to the multi fuse box.

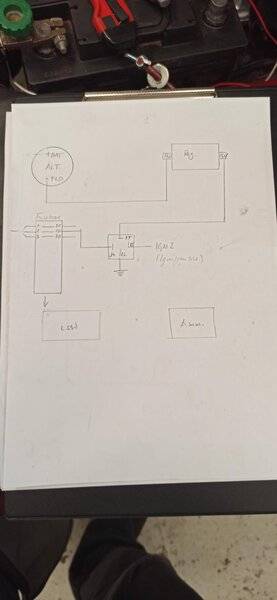

I made a simple wire diagram how it looks like here:

bad to no ground on the alt reg housing, the screws used to hold the reg have a coating and a test revealed bad current flow/high resistance so I placed as a first step an extra cable and different screws to the bulkhead.

We didn't start the engine yet, first we want to be sure we're on the right path.

Here's the question: can we just use this transistorized reg?:

Because here we have the right alt installed if I'm not mistaken the other thread Identifying Chrysler Alternators (1960-1976)

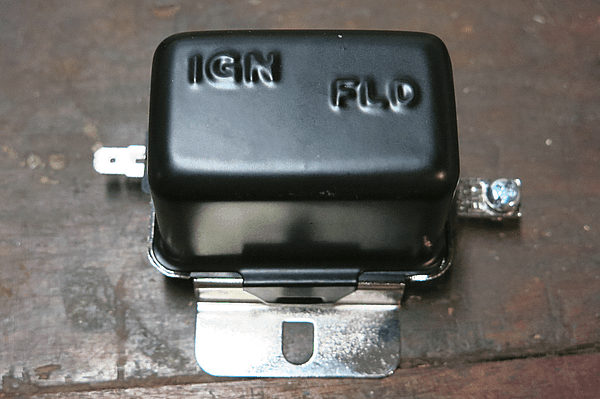

the actual grounded brush alt:

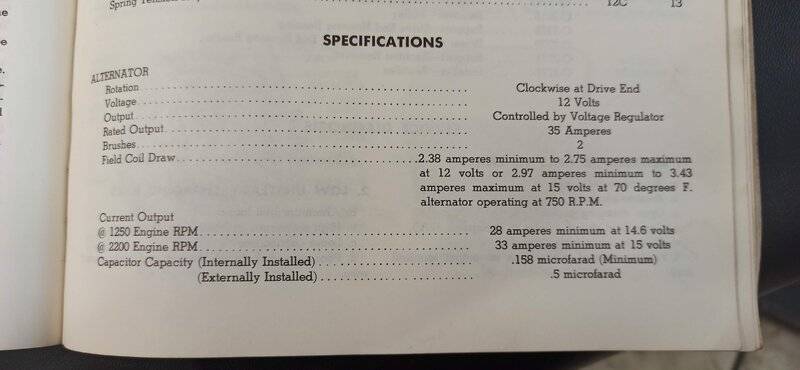

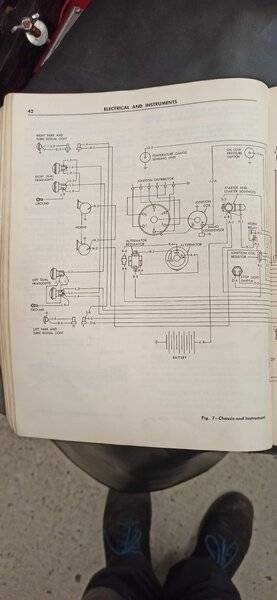

The Valiant service manual from 1960 says this:

There is also no ignition ballast / IGN coil resistor installed in this car. But there should be regarding all wire drawings so far incl. the one from @Mattax which is from 1962:

First we were trying to figure out and understand the functional differences in the electrical/ignition system on the car itself and the differences to the European (except early UK) systems. It's the first time I am working on a system like that, so it takes some time to reset the mind and don't follow the usual trouble shooting path.

What we don't understand is the difference between the field strengths is controlled by switching the positive feed, or by the negative connection.

What we checked and found so far:

the fuse box and wires are a mess, no infos what safes what.

but we searched and the red 10 Amps is going to the control relay. It's simple 40 Amps check relay that should close and open when current is applied ...

30 goes to the 10 amp fuse

85 comes from IGN2

86 goes to ground

87 goes to alt reg IGN

initially the BAT wasn't charging and the red 10 Amp fuse was popped, I replaced it. Started the engine and another 30 Amps fuse in an extra box popped, the red 10 Amps is ok. You see that there are three cables are soldered together coming from the dash and going to the multi fuse box.

I made a simple wire diagram how it looks like here:

bad to no ground on the alt reg housing, the screws used to hold the reg have a coating and a test revealed bad current flow/high resistance so I placed as a first step an extra cable and different screws to the bulkhead.

We didn't start the engine yet, first we want to be sure we're on the right path.

Here's the question: can we just use this transistorized reg?:

Because here we have the right alt installed if I'm not mistaken the other thread Identifying Chrysler Alternators (1960-1976)

the actual grounded brush alt:

The Valiant service manual from 1960 says this:

There is also no ignition ballast / IGN coil resistor installed in this car. But there should be regarding all wire drawings so far incl. the one from @Mattax which is from 1962:

Last edited:

CLBER

Member

In the service manual:

bad wire connection on the starter solenoid, it went loose my checking:

The starter and ignition shows some very small resistance fluctuation while wiggling the key in the IGN1 and IGN2 position. Would like to replace but couldn't find so far the right one.

I don't know how popular rockauto.com is in the US, but here people use it a lot for US cars.

They show only this starter / ignition switch:

There's an additional GRD contact. May it work the same way if I don't connect GRD or do we have the worng installed in the car!?

Maybe this gives also a hint to whether the field strengths is controlled by switching the positive feed, or by the negative connection ...?

#

The black wire is the one that goes from the starter switch IGN2 to the relay mentioned above, it's just connected "professionaly" to the wire:

The missing ignition ballast resistor should be connected in the engine area at this wire and the going to positive connection on the ign coil..

Ah, I forget to say: Thank you all for welcoming me here and your support.

Christian

bad wire connection on the starter solenoid, it went loose my checking:

The starter and ignition shows some very small resistance fluctuation while wiggling the key in the IGN1 and IGN2 position. Would like to replace but couldn't find so far the right one.

I don't know how popular rockauto.com is in the US, but here people use it a lot for US cars.

They show only this starter / ignition switch:

There's an additional GRD contact. May it work the same way if I don't connect GRD or do we have the worng installed in the car!?

Maybe this gives also a hint to whether the field strengths is controlled by switching the positive feed, or by the negative connection ...?

#

The black wire is the one that goes from the starter switch IGN2 to the relay mentioned above, it's just connected "professionaly" to the wire:

The missing ignition ballast resistor should be connected in the engine area at this wire and the going to positive connection on the ign coil..

Ah, I forget to say: Thank you all for welcoming me here and your support.

Christian

-