Ok, I'm trying to finish installing the under dash steering bracket.. Something is off, at least I think it is.. The plastic "bushings" or clips are out of align with the bracket when lined up with the studs.. What am I missing..?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Steering column install...

- Thread starter nodemon

- Start date

-

Mine was like that. The expanded metal portion of the column gets smashed pretty easily and throws it out of alignment. I cut the expanded metal out and replaced with some exhaust tubing of the same size.

When you say "expanded metal" are you referring to the mesh part?Mine was like that. The expanded metal portion of the column gets smashed pretty easily and throws it out of alignment. I cut the expanded metal out and replaced with some exhaust tubing of the same size.

Hmmm.. It was good when I removed it.. no smashing while restoring it...makes sense though.Mine was like that. The expanded metal portion of the column gets smashed pretty easily and throws it out of alignment. I cut the expanded metal out and replaced with some exhaust tubing of the same size.

Yes, the part that looks like patio furnitureWhen you say "expanded metal" are you referring to the mesh part?

That's how I'm taking it...I hope not... I just got all this back together..When you say "expanded metal" are you referring to the mesh part?

Be careful with that. That is a crush zone that collapses in the event of a front end collision. Replace that with a solid section and no telling what would happen in a collision.That's how I'm taking it...I hope not... I just got all this back together..

rmchrgr

Skate And Destroy

Maybe install the firewall plate after you have the column bracket where you want it. I can't remember if there are slots in that lower bracket where it bolts to the column to but if there is, leave those bolts slightly loose until you have it all positioned. There should be a small amount of fore and aft adjustment.

The breakaway biscuits, plastic shear pins in the steering shaft and the mesh section were all designed to allow the column to collapse on itself in case of a front end impact. Leave that stuff alone. Replacing the mesh section with a solid piece is not a good idea. By doing that you're effectively turning the column into a spear.

The breakaway biscuits, plastic shear pins in the steering shaft and the mesh section were all designed to allow the column to collapse on itself in case of a front end impact. Leave that stuff alone. Replacing the mesh section with a solid piece is not a good idea. By doing that you're effectively turning the column into a spear.

How would one stretch it back..? Would that mesh area being "collapsed" also mean the shaft is ruined..? Isn't there a safety issue if the shaft is collapsed..?Safety feature. stretch it back to spec

I'll give that a try.. Can you see or tell if that mesh has collapsed some..? It's kind of "wavy" to begin with, right..?Maybe install the firewall plate after you have the column bracket where you want it. I can't remember if there are slots in that lower bracket where it bolts to the column to but if there is, leave those bolts slightly loose until you have it all positioned. There should be a small amount of fore and aft adjustment.

The breakaway biscuits, plastic shear pins in the steering shaft and the mesh section were all designed to allow the column to collapse on itself in case of a front end impact. Leave that stuff alone. Replacing the mesh section with a solid piece is not a good idea. By doing that you're effectively turning the column into a spear.

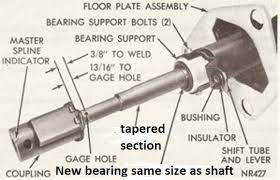

So I assume that you know not to bottom the shaft in the coupler. There is a measurement for proper depth (see pic at gauge hole). The two bolt flange at the firewall is left loose and the column is slid back or forward to get the proper depth engagement at the coupler. Once it is set, the flange bolts get tightened squeezing the rubber O ring as do the support bracket nuts.

I get impaled by the columnBe careful with that. That is a crush zone that collapses in the event of a front end collision. Replace that with a solid section and no telling what would happen in a collision.

I did not know that there was a measurement..I will check what mine is.. Thanks for that info..! Hope it's that simple.So I assume that you know not to bottom the shaft in the coupler. There is a measurement for proper depth (see pic at gauge hole). The two bolt flange at the firewall is left loose and the column is slid back or forward to get the proper depth engagement at the coupler. Once it is set, the flange bolts get tightened squeezing the rubber O ring as do the support bracket nuts.

View attachment 1716203381

My old man learned all about that column in '70 ditching the bee.. !

Yup, it's there for a reason that's for sure. No body plans on crashing.My old man learned all about that column in '70 ditching the bee.. !

View attachment 1716203386

View attachment 1716203388

View attachment 1716203389

View attachment 1716203390

View attachment 1716203391

I think you nailed it..! I'm way too deep..(that's what she said)...lol As long as my conversion is right.So I assume that you know not to bottom the shaft in the coupler. There is a measurement for proper depth (see pic at gauge hole). The two bolt flange at the firewall is left loose and the column is slid back or forward to get the proper depth engagement at the coupler. Once it is set, the flange bolts get tightened squeezing the rubber O ring as do the support bracket nuts.

View attachment 1716203381

Do as someone said.How would one stretch it back..? Would that mesh area being "collapsed

Get everything bolted up THEN tighten things.

It is really hard to collapse the outer housing tube It is not collapsed.

Last edited:

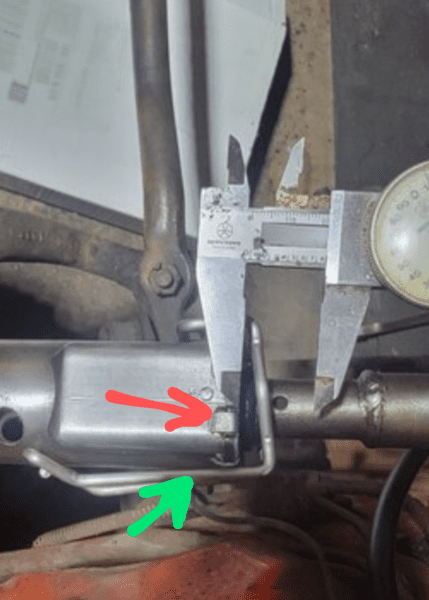

Because you successfully bent over the tabs (red) you do not need the clip ( green)

-