NukeBass

Well-Known Member

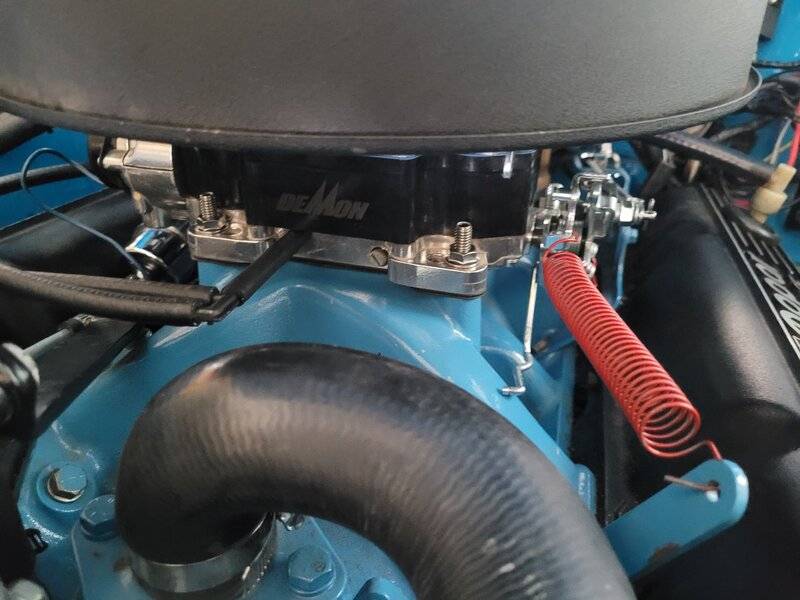

I recently nearly tuned my 625 CFM Street Demon and figured I'd share my experience. I bought this carburetor in 2015 and only recently spent the time to tune it. Lots of delays between then and now that are probably stories in themselves (and lots of helpful info from the forum) and I'm finally confident enough in the car to believe it will actually crank and run at least somewhat reliably to make tuning the carburetor worth the effort.

The car is a 73 Duster with a 340 and a small camshaft. The engine was built with a bigger camshaft, that I didn't like, and this one was recommended by Crower for a smooth idle daily driver type engine. It is a 206/212 at 0.05" (similar to the comp cams XE250, from what I can tell) that pulls 20 in Hg vacuum at a smooth idle. This plays into my tuning experience later.

I first tried tuning this a few years ago and couldn't get a reliable AFR reading, but at the time I reduced the stock Street Demon primary jetting from the 80 jet to the 76 jet and reduced the secondary jetting to 78. I don't remember what I used for the metering rods at the time. When I tested it more recently, the carburetor was still rich (in the single digits) so I took it apart to reduce the jet size more.

These carburetors were not designed for convenient tuning. If you want to change the metering rods, you can open the caps from the top, but you can't remove one of the rods because it is placed squarely under the choke arm. You have to remove the e-clip and lift that choke arm out of the way to get the rod out. I estimate I have about 10 e-clips somewhere in the engine bay or on the garage floor by now. The tuning kit only comes with 2...

To change jets you have to remove the top of the carburetor, which requires removal of 8 screws. Two on top and six on the bottom.

Aside from having to remove the carburetor to get to the six bottom screws, it's fun trying to juggle it and not spill all the gas out. I did eventually figure out I could put it on my carburetor stand and slide enough of it off the table to access one screw at a time and minimize spillage. The only thing I can figure is the designers wanted a smoother top and put the screw heads on the bottom. This process would be much easier if they were on the top.

The jets are attached to the top of the carburetor. The primary jets, the larger looking jets in the picture below, are Street Demon specific and aren't interchangeable with the standard Holley jets that are used for the secondary jets (the smaller jets in the picture). The threads are different. The Street Demon jets are shaped to fit a wrench, which I think is a good idea since I tend to strip out flat screw driver slots.

The black tube in the picture is for the accelerator pump (bottom left). I've seen where people have had troubles with this tube and replaced it with weed eater gas line, but I haven't had any issues with this tube coming off or becoming brittle yet.

The float setting is a little odd, too. It's something like 1.01" from some arbitrary point on the body to the float. It isn't exactly clear from the instructions what you measure from and that 0.01" seems really important . They are easy enough to adjust, though. I would remove the floats (the pin holding them is easy to slide out) and bend the tang so as not to risk bending anything against the needle and seat.

. They are easy enough to adjust, though. I would remove the floats (the pin holding them is easy to slide out) and bend the tang so as not to risk bending anything against the needle and seat.

I put everything back together with the 74 primary jet and did a number of test runs with it. In the end I wound up with the 74 jet and the largest metering rod in the tuning kit and I'm still a little rich in the cruise mode and lean in the power mode. During one of my tests, I had a major bog where the engine was about to stall every time I hit the gas. I got it back home and found this

The e-clip had expanded due to multiple removals and fell off, so now I know what happens when you don't have an accelerator pump connected. I have started jamming hair pin clips in place of the e-clips. So far they have held up.

At this point I discovered that there are limited parts available for this carb. If it doesn't come in one of the tuning kits (one for the 625 and one for the 750 CFM) it doesn't exist. I think I could better tune it with a 72 jet, but those don't exist and there's not a thicker metering rod to use with the 74 jet.

Another thing I eventually tested is that I don't really have a power mode, per se. I have the stiffest springs in the metering rods (8"), but with the 20" of vacuum at idle, the metering rods don't rise until I'm well into my secondaries. I haven't tested this under load, but in my garage the air door opened before the metering rods stepped up, so I think that is contributing to my lean part throttle condition. I haven't found anyone who sells a stronger step up spring to address this.

To get closer to the AFR target I think I would need a different carburetor with more available tuning parts. I'm at around 50% of the stock flow area on the primary jet/metering rod combo in cruise mode (rod full down) and 60% in power mode (rod up). I can find similar reductions from stock for the Edelbrock AVS2, so jet/metering rod parts are available, but that doesn't address the delayed step up from the 8 in Hg step up spring.

I've also looked a little bit at the more traditional Holley carburetors, but that would be a whole different learning curve. I saw where they sell a 10.5" power valve, which would match the half the idle vacuum recommendation, and there's a risk there of swapping the carb and not getting the results I want, too.

Cheapest and easiest option is to run this one until it wears out, but it's always tempting to try something new. The parts canon solves everything!!

Most people won't have the limiting jetting or spring issues I have, so these probably aren't relevant to most people who buy this carb. Once you get past the tedium of tuning it, though, the carb runs well and you shouldn't have to tune it too often (at least I hope not) so the tedium would be a short term thing.

Three quarters (or more) of the youtube videos say all you have to do is throw the carburetor on and turn the idle mixture screws and you're done! Greatest carb ever!! Too bad that wasn't the case for me. My mileage has improved at least a little, though. I haven't run through enough tanks to get a good idea of what I'm really getting, but so far it is better than the 10-11 mpg I was getting before and I think was worth the effort at least to this point.

The car is a 73 Duster with a 340 and a small camshaft. The engine was built with a bigger camshaft, that I didn't like, and this one was recommended by Crower for a smooth idle daily driver type engine. It is a 206/212 at 0.05" (similar to the comp cams XE250, from what I can tell) that pulls 20 in Hg vacuum at a smooth idle. This plays into my tuning experience later.

I first tried tuning this a few years ago and couldn't get a reliable AFR reading, but at the time I reduced the stock Street Demon primary jetting from the 80 jet to the 76 jet and reduced the secondary jetting to 78. I don't remember what I used for the metering rods at the time. When I tested it more recently, the carburetor was still rich (in the single digits) so I took it apart to reduce the jet size more.

These carburetors were not designed for convenient tuning. If you want to change the metering rods, you can open the caps from the top, but you can't remove one of the rods because it is placed squarely under the choke arm. You have to remove the e-clip and lift that choke arm out of the way to get the rod out. I estimate I have about 10 e-clips somewhere in the engine bay or on the garage floor by now. The tuning kit only comes with 2...

To change jets you have to remove the top of the carburetor, which requires removal of 8 screws. Two on top and six on the bottom.

Aside from having to remove the carburetor to get to the six bottom screws, it's fun trying to juggle it and not spill all the gas out. I did eventually figure out I could put it on my carburetor stand and slide enough of it off the table to access one screw at a time and minimize spillage. The only thing I can figure is the designers wanted a smoother top and put the screw heads on the bottom. This process would be much easier if they were on the top.

The jets are attached to the top of the carburetor. The primary jets, the larger looking jets in the picture below, are Street Demon specific and aren't interchangeable with the standard Holley jets that are used for the secondary jets (the smaller jets in the picture). The threads are different. The Street Demon jets are shaped to fit a wrench, which I think is a good idea since I tend to strip out flat screw driver slots.

The black tube in the picture is for the accelerator pump (bottom left). I've seen where people have had troubles with this tube and replaced it with weed eater gas line, but I haven't had any issues with this tube coming off or becoming brittle yet.

The float setting is a little odd, too. It's something like 1.01" from some arbitrary point on the body to the float. It isn't exactly clear from the instructions what you measure from and that 0.01" seems really important

I put everything back together with the 74 primary jet and did a number of test runs with it. In the end I wound up with the 74 jet and the largest metering rod in the tuning kit and I'm still a little rich in the cruise mode and lean in the power mode. During one of my tests, I had a major bog where the engine was about to stall every time I hit the gas. I got it back home and found this

The e-clip had expanded due to multiple removals and fell off, so now I know what happens when you don't have an accelerator pump connected. I have started jamming hair pin clips in place of the e-clips. So far they have held up.

At this point I discovered that there are limited parts available for this carb. If it doesn't come in one of the tuning kits (one for the 625 and one for the 750 CFM) it doesn't exist. I think I could better tune it with a 72 jet, but those don't exist and there's not a thicker metering rod to use with the 74 jet.

Another thing I eventually tested is that I don't really have a power mode, per se. I have the stiffest springs in the metering rods (8"), but with the 20" of vacuum at idle, the metering rods don't rise until I'm well into my secondaries. I haven't tested this under load, but in my garage the air door opened before the metering rods stepped up, so I think that is contributing to my lean part throttle condition. I haven't found anyone who sells a stronger step up spring to address this.

To get closer to the AFR target I think I would need a different carburetor with more available tuning parts. I'm at around 50% of the stock flow area on the primary jet/metering rod combo in cruise mode (rod full down) and 60% in power mode (rod up). I can find similar reductions from stock for the Edelbrock AVS2, so jet/metering rod parts are available, but that doesn't address the delayed step up from the 8 in Hg step up spring.

I've also looked a little bit at the more traditional Holley carburetors, but that would be a whole different learning curve. I saw where they sell a 10.5" power valve, which would match the half the idle vacuum recommendation, and there's a risk there of swapping the carb and not getting the results I want, too.

Cheapest and easiest option is to run this one until it wears out, but it's always tempting to try something new. The parts canon solves everything!!

Most people won't have the limiting jetting or spring issues I have, so these probably aren't relevant to most people who buy this carb. Once you get past the tedium of tuning it, though, the carb runs well and you shouldn't have to tune it too often (at least I hope not) so the tedium would be a short term thing.

Three quarters (or more) of the youtube videos say all you have to do is throw the carburetor on and turn the idle mixture screws and you're done! Greatest carb ever!! Too bad that wasn't the case for me. My mileage has improved at least a little, though. I haven't run through enough tanks to get a good idea of what I'm really getting, but so far it is better than the 10-11 mpg I was getting before and I think was worth the effort at least to this point.

...

...