weedburner

Well-Known Member

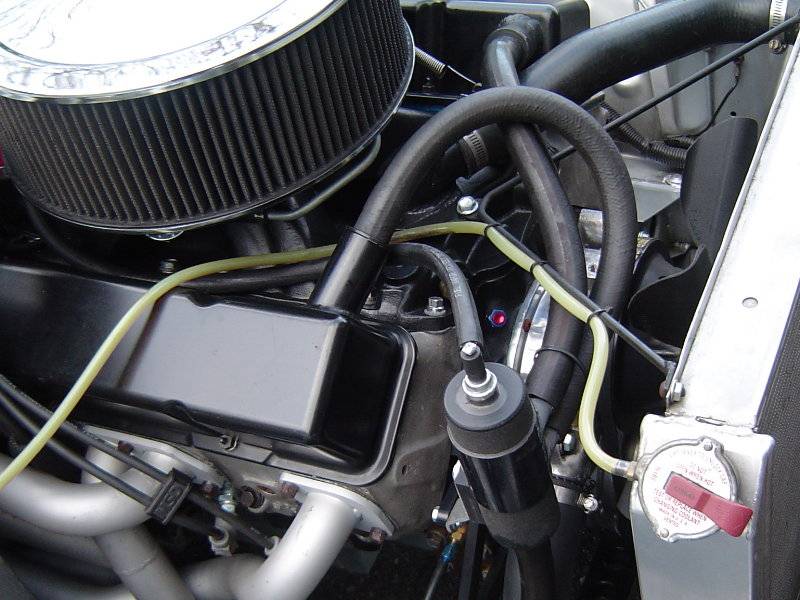

Here's the evac system I had been using. These valve covers are a circle track design that originally used a crossover tube with a couple small breathers, I eliminated the crossover setup and made some adapters to plumb them into a separator can that I had also installed a pcv valve into. The hose out the bottom is connected to a standpipe inside the separator, other end of that hose connected to the inlet of the electric pump. Outlet of the electric pump had a large header evac style check valve to eliminate the vacuum leak when the pump was not turned on. Using the pcv valve as a crankcase vacuum source worked so well that I rarely turned on the electric pump, got to the point that I considered the electric pump system as dead weight.

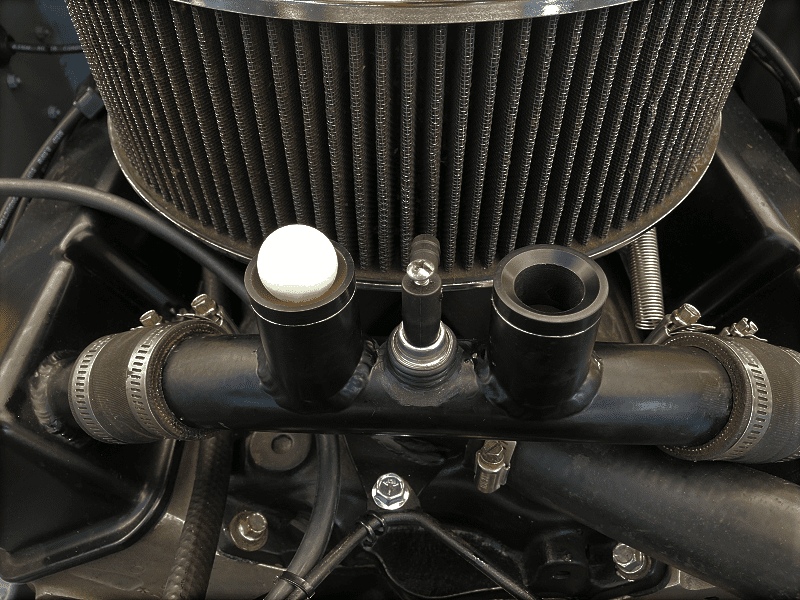

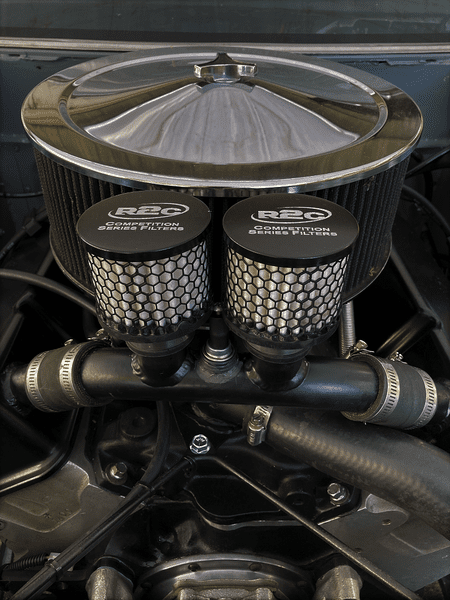

I ended up eliminating the hoses, separator, electric pump, and check valve. I replaced them with a modified version of the original crossover tube. Basically I made some Delrin check ball seats that fit inside the aluminum crossover tube's breather standpipes...

For the check balls, I bought some 1" dia nylon bearing balls, cost me around $5. I also installed my homemade adjustable pcv valve that had formerly been installed in the separator...

The plastic elbow on the pcv valve rotates, I pointed it off to the side and attached it to it's hose.

These check balls are pretty light-weight, launching the car does not cause them to become un-seated and leak crankcase vacuum.

Grant

I ended up eliminating the hoses, separator, electric pump, and check valve. I replaced them with a modified version of the original crossover tube. Basically I made some Delrin check ball seats that fit inside the aluminum crossover tube's breather standpipes...

For the check balls, I bought some 1" dia nylon bearing balls, cost me around $5. I also installed my homemade adjustable pcv valve that had formerly been installed in the separator...

The plastic elbow on the pcv valve rotates, I pointed it off to the side and attached it to it's hose.

These check balls are pretty light-weight, launching the car does not cause them to become un-seated and leak crankcase vacuum.

Grant

Last edited: