MR4V

Well-Known Member

Hi All

Wanting a little advice on improving my suspension set up for racing on the Duster, as I believe there is some improvement to be made.

Here's what I have so far: front is stock A Body fully rebuilt, running competition 3 way adjustable set at 90/10, still have the sway bar connected, S/6 torsion bars.

Rear has new Mopar leaf springs, competition 3 way adjustable both sides set at 50/50, 8 3/4 running Mopar snubber.

I'm currently not running chassis connectors and haven't tried unclamping the rear spring clamps.

When I race I run MT ET radials that are 255/60 15, tyre pressure varries upon the track but usually between 16-14psi.

60 feet times are consistent at low 1.7 to high 1.6, Duster seams to launch best at 2800rpm, again depending on the track some times I get wheel spin sometimes not.

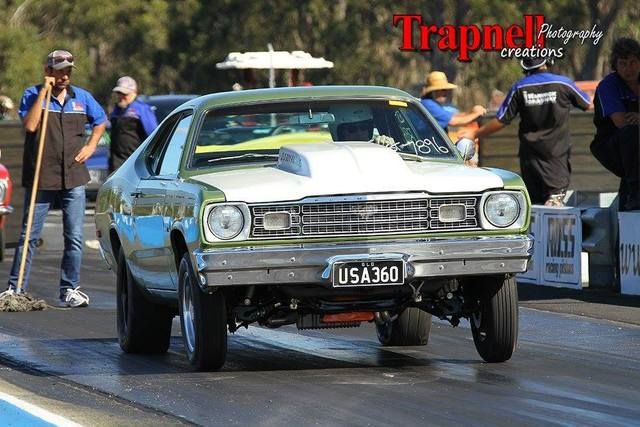

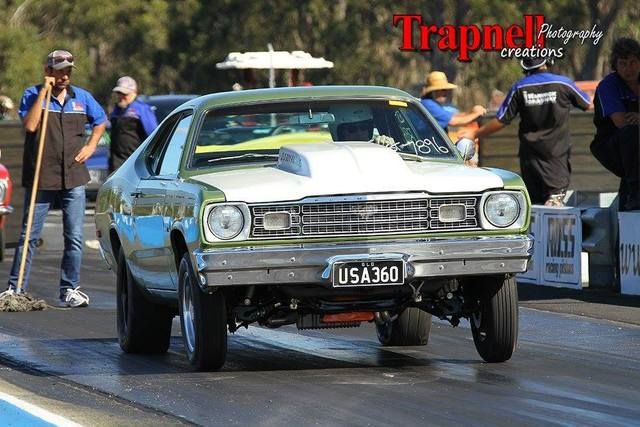

You can see in the photos that the drivers side rear tyre is getting side wall wrinkle yet the passages side is fine, is this normal for these? Can you see any improvement that can be made to my current set up?

Cheers

Karl

This run is launch at 2800rpm with 16 psi

These runs have the same launch and have 14 psi.

Normal stance

Wanting a little advice on improving my suspension set up for racing on the Duster, as I believe there is some improvement to be made.

Here's what I have so far: front is stock A Body fully rebuilt, running competition 3 way adjustable set at 90/10, still have the sway bar connected, S/6 torsion bars.

Rear has new Mopar leaf springs, competition 3 way adjustable both sides set at 50/50, 8 3/4 running Mopar snubber.

I'm currently not running chassis connectors and haven't tried unclamping the rear spring clamps.

When I race I run MT ET radials that are 255/60 15, tyre pressure varries upon the track but usually between 16-14psi.

60 feet times are consistent at low 1.7 to high 1.6, Duster seams to launch best at 2800rpm, again depending on the track some times I get wheel spin sometimes not.

You can see in the photos that the drivers side rear tyre is getting side wall wrinkle yet the passages side is fine, is this normal for these? Can you see any improvement that can be made to my current set up?

Cheers

Karl

This run is launch at 2800rpm with 16 psi

These runs have the same launch and have 14 psi.

Normal stance