LT1-LS1 T56 Transmission Conversion:

So, I am getting ready to swap a T56 into my 440 dart. I, like so many others, looked for the cheapest route to do this. Let me preference this by saying that IF you are swapping a 6 speed manual into your older Mopar to go behind a Hemi or even an LA series, odds are, you will be money and time ahead going with a TR6060 transmission from a newer Challenger. By the time you buy a Brand X T56 and convert it, the cost savings will be very minimal, if any. Of course, if you are like me, running a big block or have the need/desire to run an SFI approved bellhousing, then yes, a Brand X or a Viper T56 are about the best options.

First, let’s understand the T56 and where you may find them.

The T56 has several variants over the years. Member, @Riddler, has a very good writeup on some of these differences, found here. T-56 Transmission Install Thread

Early models can be had in a variety of cars, ranging from the Viper, to Ford Mustangs, Camaros, even in the SRT10 pickups. Going prices range from 500 to 5000. By far, the most popular and easiest to find, equating to the cheapest option for the transmission itself is the LT1 Version offered in the GM F-Body cars, (Firebirds, Camaros from 1993-1997). That said, there are a few drawbacks to this, which is why I write this up. I purchased an LT1 T56 for 600 bucks.

There are actually TWO, versions of the LT1 T56. While you can search the TAG numbers, I’ve found that often times the paper tags are missing, or unreadable and who knows what someone may have done to it throughout the years. The best way and only surefire way to know for sure which version you have, is to pull the midplate and input shaft and simply count the number of teeth on the input shaft gear. DO NOT, DO NOT rely on the casting numbers on the case components. They used the same numbers on the cases for a variety of engine/year/model combos, and there is no way short of the paper tag of knowing if you have a 29 or 31 tooth input. Again, count the teeth.

There are only 2 options for the number of gear teeth. 29 or 31. If you have a 29 tooth gear on your input shaft, walk away from it, sell it, scrap it etc. It can NOT be used in a swap and there is no converting it to a 31 tooth set without replacing literally, all the internals. It is also the weakest T56 as a ft lb rating of 350. The 29 tooth was a one year only transmission, 1993 and only in some lower performance model GM Cars. They are a bit rarer because of that but do come up from time to time. So before buying, verify the tooth count.

The 31 tooth count is the one you want. This will allow you to do the conversion I am about to walk you through. Because of the short length of the LT1 input shaft, combined with the fact no one makes an LT1 to Mopar anything bellhousing, the swap to an LS1 style mid-plate and input shaft is required. Again, only can be done on a 31 tooth input gear set.

LS1 input on the left, LT1 input on the right.

After much research, the best deal is to get the complete kit from RS Gear in New York. This kit will set you back roughly 490 bucks but includes EVERYTHING needed to do this swap, including bearings, shims, bolts, instructions etc. You can piece-meal this kit on your own via the world wide web, however, this kit came out cheaper in price.

Kit from RS Gear is part number LT1/LS1.

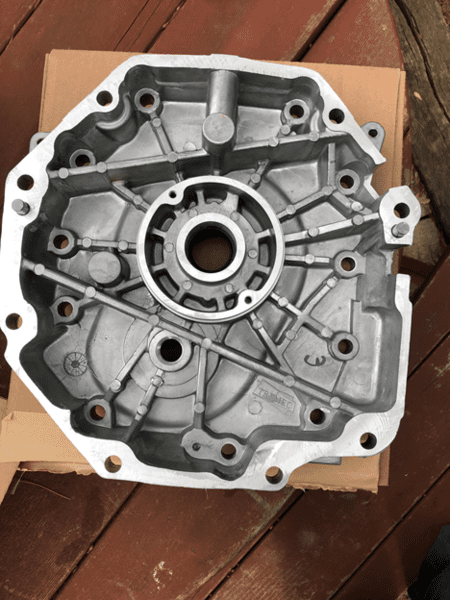

LS1 Midplate above

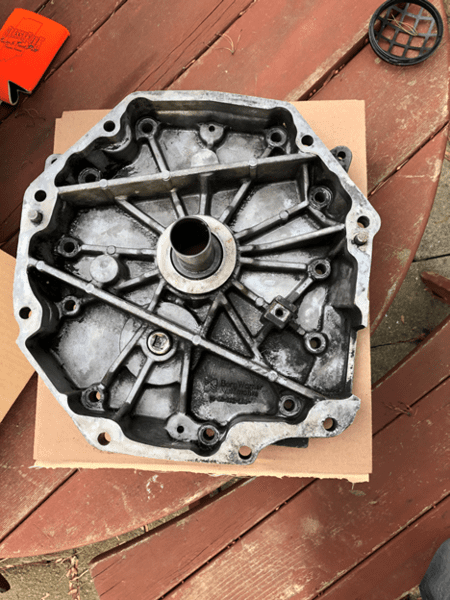

LT1 Midplate below, notice the provisions for a clutch lever/throw out bearing arm.

LT1 Midplate Above.

Components of the RSG Kit. Notice the varying shims it includes as well as the bearings.

More to follow as I go through this.

So, I am getting ready to swap a T56 into my 440 dart. I, like so many others, looked for the cheapest route to do this. Let me preference this by saying that IF you are swapping a 6 speed manual into your older Mopar to go behind a Hemi or even an LA series, odds are, you will be money and time ahead going with a TR6060 transmission from a newer Challenger. By the time you buy a Brand X T56 and convert it, the cost savings will be very minimal, if any. Of course, if you are like me, running a big block or have the need/desire to run an SFI approved bellhousing, then yes, a Brand X or a Viper T56 are about the best options.

First, let’s understand the T56 and where you may find them.

The T56 has several variants over the years. Member, @Riddler, has a very good writeup on some of these differences, found here. T-56 Transmission Install Thread

Early models can be had in a variety of cars, ranging from the Viper, to Ford Mustangs, Camaros, even in the SRT10 pickups. Going prices range from 500 to 5000. By far, the most popular and easiest to find, equating to the cheapest option for the transmission itself is the LT1 Version offered in the GM F-Body cars, (Firebirds, Camaros from 1993-1997). That said, there are a few drawbacks to this, which is why I write this up. I purchased an LT1 T56 for 600 bucks.

There are actually TWO, versions of the LT1 T56. While you can search the TAG numbers, I’ve found that often times the paper tags are missing, or unreadable and who knows what someone may have done to it throughout the years. The best way and only surefire way to know for sure which version you have, is to pull the midplate and input shaft and simply count the number of teeth on the input shaft gear. DO NOT, DO NOT rely on the casting numbers on the case components. They used the same numbers on the cases for a variety of engine/year/model combos, and there is no way short of the paper tag of knowing if you have a 29 or 31 tooth input. Again, count the teeth.

There are only 2 options for the number of gear teeth. 29 or 31. If you have a 29 tooth gear on your input shaft, walk away from it, sell it, scrap it etc. It can NOT be used in a swap and there is no converting it to a 31 tooth set without replacing literally, all the internals. It is also the weakest T56 as a ft lb rating of 350. The 29 tooth was a one year only transmission, 1993 and only in some lower performance model GM Cars. They are a bit rarer because of that but do come up from time to time. So before buying, verify the tooth count.

The 31 tooth count is the one you want. This will allow you to do the conversion I am about to walk you through. Because of the short length of the LT1 input shaft, combined with the fact no one makes an LT1 to Mopar anything bellhousing, the swap to an LS1 style mid-plate and input shaft is required. Again, only can be done on a 31 tooth input gear set.

LS1 input on the left, LT1 input on the right.

After much research, the best deal is to get the complete kit from RS Gear in New York. This kit will set you back roughly 490 bucks but includes EVERYTHING needed to do this swap, including bearings, shims, bolts, instructions etc. You can piece-meal this kit on your own via the world wide web, however, this kit came out cheaper in price.

Kit from RS Gear is part number LT1/LS1.

LS1 Midplate above

LT1 Midplate below, notice the provisions for a clutch lever/throw out bearing arm.

LT1 Midplate Above.

Components of the RSG Kit. Notice the varying shims it includes as well as the bearings.

More to follow as I go through this.

Last edited: