As I’ve told a few of you guys I’ve struggled on back to back sets of heads. One a set of 2.08 with a customer that wants to run a 4.080 head gasket and now a set of 2.055 valve heads with a 4.120 head gasket size. Seeing me struggling he’s open to a bigger gasket. So I took a couple days to pout, almost throw things, and a lot of thinking. I grabbed my son Ethan set of 2.02 valved heads tonight because they are already tubed, set the runner to 2.055 sizes, cut a 2.055 seat on that runner, and blended the valve job. So hopefully tomorrow four different flow tests will be done on what I hope I came up with to fix the smaller head gasket issues. Final two test will be with the 4.180 ( felpro) size. I’ll either be extremely happy or madder than a bunch of pissed off hornets. After this is two sets with stock 2.02 valves but one of the customers is second guessing his choice and may go with a 2.055 valve. Because I modified Ethans head he will be getting a nice set of 2.055 heads now.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Test test test

- Thread starter pittsburghracer

- Start date

-

abdywgn

dismantler

Thank-you again and looking forward to another learning experience.

Does a 4.180 gasket allow to make about 1/8-3/16 of deshroulding with 2.055-2.08 valves ?As I’ve told a few of you guys I’ve struggled on back to back sets of heads. One a set of 2.08 with a customer that wants to run a 4.080 head gasket and now a set of 2.055 valve heads with a 4.120 head gasket size. Seeing me struggling he’s open to a bigger gasket. So I took a couple days to pout, almost throw things, and a lot of thinking. I grabbed my son Ethan set of 2.02 valved heads tonight because they are already tubed, set the runner to 2.055 sizes, cut a 2.055 seat on that runner, and blended the valve job. So hopefully tomorrow four different flow tests will be done on what I hope I came up with to fix the smaller head gasket issues. Final two test will be with the 4.180 ( felpro) size. I’ll either be extremely happy or madder than a bunch of pissed off hornets. After this is two sets with stock 2.02 valves but one of the customers is second guessing his choice and may go with a 2.055 valve. Because I modified Ethans head he will be getting a nice set of 2.055 heads now.

Does a 4.180 gasket allow to make about 1/8-3/16 of deshroulding with 2.055-2.08 valves ?

I never actually measured it but when you have steep ugly chambers like small block Mopars has it allows you to shape it a little bit. (Pictures of 4.120 mark. 4.180 felpro gasket) that we all ran for years. I only wish I had my heads off my engine to take a 30 second look at them. When I ported them in 2008 I’m about 99% sure I opened the chambers to 4.180 because I ran that gasket on three or four different engines. Those heads flowed 318cfm with the help of my Super Victor intake. Now for three years I’ve ran a 4.060 Cometic head gasket and didn’t burn it out. So am I worried about something for nothing. Hmmmmm time will tell when hopefully I pull them and put a better set on

- Joined

- Apr 16, 2009

- Messages

- 6,274

- Reaction score

- 9,375

I heard that.As I’ve told a few of you guys I’ve struggled on back to back sets of heads. One a set of 2.08 with a customer that wants to run a 4.080 head gasket and now a set of 2.055 valve heads with a 4.120 head gasket size. Seeing me struggling he’s open to a bigger gasket. So I took a couple days to pout, almost throw things, and a lot of thinking. I grabbed my son Ethan set of 2.02 valved heads tonight because they are already tubed, set the runner to 2.055 sizes, cut a 2.055 seat on that runner, and blended the valve job. So hopefully tomorrow four different flow tests will be done on what I hope I came up with to fix the smaller head gasket issues. Final two test will be with the 4.180 ( felpro) size. I’ll either be extremely happy or madder than a bunch of pissed off hornets. After this is two sets with stock 2.02 valves but one of the customers is second guessing his choice and may go with a 2.055 valve. Because I modified Ethans head he will be getting a nice set of 2.055 heads now.

Earlie A

Well-Known Member

So if the chamber is 4.180 and I assume a bore of 4.08, then the bore gets a 0.050 (minimum) chamfer?I never actually measured it but when you have steep ugly chambers like small block Mopars has it allows you to shape it a little bit. (Pictures of 4.120 mark. 4.180 felpro gasket) that we all ran for years. I only wish I had my heads off my engine to take a 30 second look at them. When I ported them in 2008 I’m about 99% sure I opened the chambers to 4.180 because I ran that gasket on three or four different engines. Those heads flowed 318cfm with the help of my Super Victor intake. Now for three years I’ve ran a 4.060 Cometic head gasket and didn’t burn it out. So am I worried about something for nothing. Hmmmmm time will tell when hopefully I pull them and put a better set on

View attachment 1716209530

View attachment 1716209532

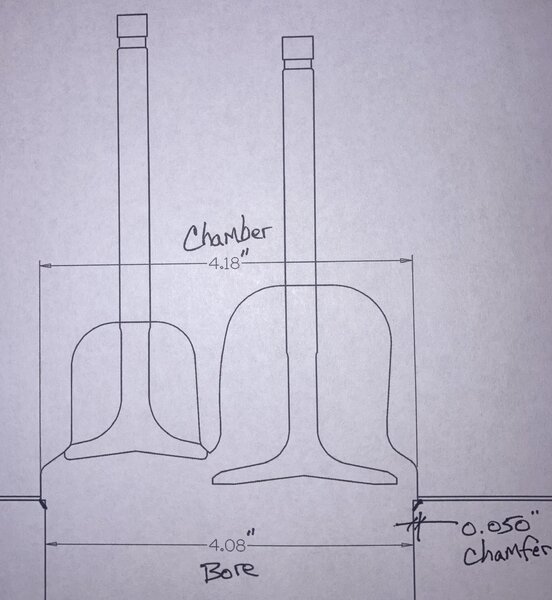

So if the chamber is 4.180 and I assume a bore of 4.08, then the bore gets a 0.050 (minimum) chamfer?

If you are talking about my engine I think back in 2008 I laid the head out for a 1008 felpro gasket as I ran those up till my last two builds. So to simplify things it’s a .030 over 360 (4.030) so Cometic recommends a .030 bigger gasket to bore size. So my chamber again is probably because it’s on my engine reworked for a 4.180 chamber size running a 4.060 gasket. I don’t mind answering questions but please try to really take time to ask specific questions. In this post especially because of all the heads involved.

Earlie A

Well-Known Member

See the drawing below. If the chamber is 4.180" wide and the bore is 4.080" wide, there is a 0.100" mismatch which is not good for flow. Is the best option to use a 4.180" gasket and use a 0.050" chamfer on the top of the bore? That's a pretty large chamfer. Your engine is a 4.030" bore with a 4.180" chamber, which would make for a larger mismatch.

See the drawing below. If the chamber is 4.180" wide and the bore is 4.080" wide, there is a 0.100" mismatch which is not good for flow. Is the best option to use a 4.180" gasket and use a 0.050" chamfer on the top of the bore? That's a pretty large chamfer. Your engine is a 4.030" bore with a 4.180" chamber, which would make for a larger mismatch.

View attachment 1716209798

Trust me I know. But if it hurts so bad how does this engine last and run 6.0’s (9.30’s in the 1/4). It’s three years old. Inquiring minds want to know. I do know you have to work the chamber to get them up over 300cfm. I personally will give up compression for flow any day of the week.

Brian Hafliger

Well-Known Member

See the drawing below. If the chamber is 4.180" wide and the bore is 4.080" wide, there is a 0.100" mismatch which is not good for flow. Is the best option to use a 4.180" gasket and use a 0.050" chamfer on the top of the bore? That's a pretty large chamfer. Your engine is a 4.030" bore with a 4.180" chamber, which would make for a larger mismatch.

View attachment 1716209798

The chamber wall is, in reality much taller than your drawing...if you do it right (chamber shape from the seat to the deck) the bore intrusion is no big deal honestly and it does make more power than keeping it tight like say a 4.080 gasket bore. I don't do this as much now as I've learned how to make the same power while keeping the chamber tighter than I used to. But it works.

Well I did three flow tests and still not totally satisfied. It’s nicely up over 300 but not acting how I want it to. But now I can reshape a few things. Time to eat and get off my knees some so probably be Thursday now to test again. Dentist and tax appointment’s tomorrow.

Ok busy morning with a dental checkup and cleaning and some banking but I squeezed in a couple of shop hours before having to get ready to get my taxes done. On a reworked 4.120 gasket bore I got one quick dip at .650 that most guys flowing at .100 lift numbers wouldn’t see. It’s now maxing out at 310@.700 and 315@.750. I reworked my sons head with the 4.180 felpro sized chamber and hopefully will flow it tomorrow with the same 2.055 Ferrea valve.

Dale Davies

Well-Known Member

The gasket inner diameter is pretty much always larger than the bore. It is the cylinder wall that is the source of shrouding once lift gets the valve head at and past the gasket. Rather than using the gasket, I use the cylinder bore to scribe the never exceed diameter on the head.Does a 4.180 gasket allow to make about 1/8-3/16 of deshroulding with 2.055-2.08 valves ?

The gasket inner diameter is pretty much always larger than the bore. It is the cylinder wall that is the source of shrouding once lift gets the valve head at and past the gasket. Rather than using the gasket, I use the cylinder bore to scribe the never exceed diameter on the head.

You guys that think this way are totally wrong when talking about a head like a small block Mopar Speedmaster or Edelbrock head. I try to share what I learn but if you want to be a cement head, help yourself. All heads are not alike, and all chambers are different animals.

Dale Davies

Well-Known Member

Yup, I got that. The gasket bore has to be at least as big as the cylinder bote or it overhangs. Now with talking a 4.180" gasket bore you must be talking BBM. If you use the 4.180" gasket to scribe your limits for an engine with a 4.120" bore, you can have a 0.060" lip to catch the incoming air/fuel. This will cause a restriction which damages flow into the cylinder.You guys that think this way are totally wrong when talking about a head like a small block Mopar Speedmaster or Edelbrock head. I try to share what I learn but if you want to be a cement head, help yourself. All heads are not alike, and all chambers are different animals.

You need not be insulting with that cement head road apples stuff!

Yup, I got that. The gasket bore has to be at least as big as the cylinder bote or it overhangs. Now with talking a 4.180" gasket bore you must be talking BBM. If you use the 4.180" gasket to scribe your limits for an engine with a 4.120" bore, you can have a 0.060" lip to catch the incoming air/fuel. This will cause a restriction which damages flow into the cylinder.

You need not be insulting with that cement head road apples stuff!

You believe what you believe and I’ll believe what I believe and have tested weekly at the drag strip. Do you mind starting your own posts for your lectures or do you just step on everyone else’s posts. It’s not that hard to do.

I think that's a little unfair, don't think anyone knocking your work just I think It's natural to assume the chamber shouldn't be bigger than the bore, even though that's probably only based on assumptions without any empirical evidence, I sure someone out there had dyno/track test the **** out this but most of us not privy to this info, so when someone does exceed assumptions it might bring up some questions.You guys that think this way are totally wrong when talking about a head like a small block Mopar Speedmaster or Edelbrock head. I try to share what I learn but if you want to be a cement head, help yourself. All heads are not alike, and all chambers are different animals.

From what I remember your testing on a 4.03" bore so if your gaining 20+ cfm by going larger than bore especially if you found it's the only way to gain this then the results speak for themselves, cause it's fair to assume that gain will also apply to the dyno and track. I imagine there would be some more gains on larger bores. Have you ever tested them on larger bores ?

I think that's a little unfair, don't think anyone knocking your work just I think It's natural to assume the chamber shouldn't be bigger than the bore, even though that's probably only based on assumptions without any empirical evidence, I sure someone out there had dyno/track test the **** out this but most of us not privy to this info, so when someone does exceed assumptions it might bring up some questions.

From what I remember your testing on a 4.03" bore so if your gaining 20+ cfm by going larger than bore especially if you found it's the only way to gain this then the results speak for themselves, cause it's fair to assume that gain will also apply to the dyno and track. I imagine there would be some more gains on larger bores. Have you ever tested them on larger bores ?

My biggest gripe is if you know so much start a post and “teach us”. But no they don’t do that. They would rather come on someone’s post that is trying to teach a few findings and spin their story. I don’t know if this guy runs 11’s or really knows something and runs 8’s. If you are talking about an Indy head or some other head then in your post I would know this. Every small block head I test is on a 4.015 cylinder size flow adapter and sealed with a 4.180 (1008 felpro gasket). So if the flowbench findings isn’t enough you know what my car runs. These heads have been on 3 (4.030) and 1 (4.040) engines that have run 9.30’s-10.30’s on a 2850 car and 3200 pound car. So flowbench numbers backed up by track numbers. 4.180 chamber on these bores. When the valves clears the deck surface it has 4.030 inches of area to flow into. A properly ported head has air directed towards the center of the cylinder NOT the cylinder wall. This takes effort and is why we get rich porting heads. If the chamber is crowded in on the valve, especially with the sucky azz small block chamber if you don’t give it room suffers from .100-1.00 every time the valve opens and closes. After todays flow numbers I’m done teaching for awhile because I’m tired of explaining things over and over. Step up guys, teach us.

From one of the guys that sit back, shut up, and learn, Thanks for all that you do post.My biggest gripe is if you know so much start a post and “teach us”. But no they don’t do that. They would rather come on someone’s post that is trying to teach a few findings and spin their story. I don’t know if this guy runs 11’s or really knows something and runs 8’s. If you are talking about an Indy head or some other head then in your post I would know this. Every small block head I test is on a 4.015 cylinder size flow adapter and sealed with a 4.180 (1008 felpro gasket). So if the flowbench findings isn’t enough you know what my car runs. These heads have been on 3 (4.030) and 1 (4.040) engines that have run 9.30’s-10.30’s on a 2850 car and 3200 pound car. So flowbench numbers backed up by track numbers. 4.180 chamber on these bores. When the valves clears the deck surface it has 4.030 inches of area to flow into. A properly ported head has air directed towards the center of the cylinder NOT the cylinder wall. This takes effort and is why we get rich porting heads. If the chamber is crowded in on the valve, especially with the sucky azz small block chamber if you don’t give it room suffers from .100-1.00 every time the valve opens and closes. After todays flow numbers I’m done teaching for awhile because I’m tired of explaining things over and over. Step up guys, teach us.

From one of the guys that sit back, shut up, and learn, Thanks for all that you do post.

I don’t mind a discussion but give me proof that something i

Doing doesn’t work because I’m proving it does work. Dog gone Canadian rattles on and I don’t even know if he races let alone does any head porting.

-

Similar threads

- Replies

- 57

- Views

- 4K

- Replies

- 11

- Views

- 570

- Replies

- 346

- Views

- 26K

- Replies

- 6

- Views

- 242

- Replies

- 4

- Views

- 741