VIOLENT\6

12 second N/A Slant 6?

If I run 89mm 2.2L Turbo pistons W/-18cc voluume on 7.005" Molnar rods,

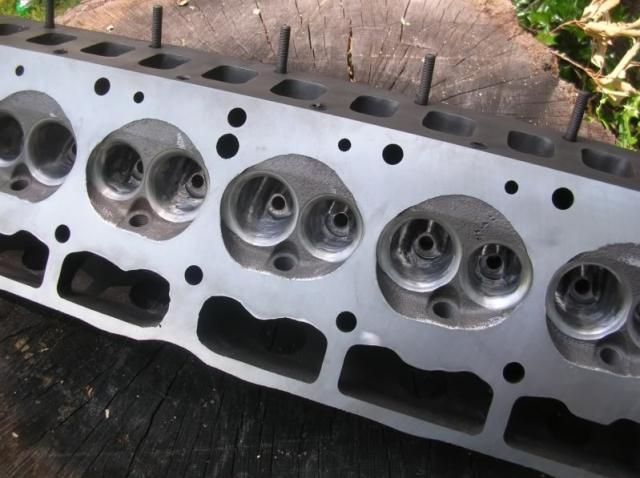

reduce the head deck by .110", have the combustion chamber perimeter cut to allow the piston crown to enter the chamber & run the pistons at +.070" positive deck W/a .035" head gasket, I can achieve .055" quench height at about 12.8:1 CR. A small amount of offset grind on the crank and/or some block decking work may be needed to get to those specs depending on the existing deck height.

This will make pump gas a bit low on octane so either additives or water methanol injection will be required & nitrous will be out of the question.

The other alternative would be to run .000" deck on the pistons W/10.5:1 CR.

That would allow using 93 octane pump gas & have a 125 shot of nitrous on tap just for giggles.

What say ye Slant 6 gurus?

Would 12.3:1 be feasable W/the right cam to bleed off chamber pressure at lower RPM to allow 93 octane fuel?

Will mechanical octane (quench) make enough difference to allow 93 octane pump gas use?

Would the HP difference between 12.8 & 10.5 be enough to not have the nitrous option. I know that the lower CR engine on juice would blow away the high CR engine, but compairing both in N/A form, what would the power difference be?

Would the 12.8:1 CR make my 12.99 N/A goal a little easier to reach?

reduce the head deck by .110", have the combustion chamber perimeter cut to allow the piston crown to enter the chamber & run the pistons at +.070" positive deck W/a .035" head gasket, I can achieve .055" quench height at about 12.8:1 CR. A small amount of offset grind on the crank and/or some block decking work may be needed to get to those specs depending on the existing deck height.

This will make pump gas a bit low on octane so either additives or water methanol injection will be required & nitrous will be out of the question.

The other alternative would be to run .000" deck on the pistons W/10.5:1 CR.

That would allow using 93 octane pump gas & have a 125 shot of nitrous on tap just for giggles.

What say ye Slant 6 gurus?

Would 12.3:1 be feasable W/the right cam to bleed off chamber pressure at lower RPM to allow 93 octane fuel?

Will mechanical octane (quench) make enough difference to allow 93 octane pump gas use?

Would the HP difference between 12.8 & 10.5 be enough to not have the nitrous option. I know that the lower CR engine on juice would blow away the high CR engine, but compairing both in N/A form, what would the power difference be?

Would the 12.8:1 CR make my 12.99 N/A goal a little easier to reach?