Don’t understand why trick flow heads are offered in different installed valve heights????

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Trick flow heads: different installed valve height

- Thread starter Brooks James

- Start date

-

yellow rose

Overnight Sensation

Don’t understand why trick flow heads are offered in different installed valve heights????

So you can get the correct spring for the correct lobes. All the valves are the same length so they change the installed height per the spring and application.

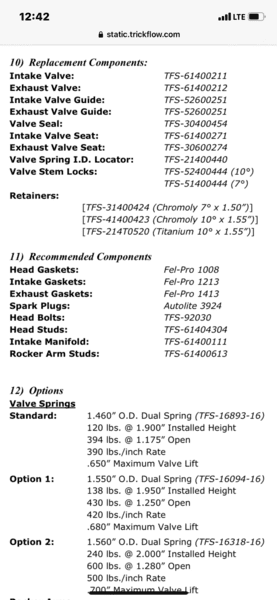

The baseline heads have the 1.90” installed height using standard retainers, spring locators and shims (mine have one .015” shim) under the locators to yield that installed height. The other more costly versions utilize retainers with +.050” and “likely” +.100” for the 1.950” and 2.00” installed heights respectively. (They may cut the spring seats for the 2.00” installed version, I’m not sure) The valves and spring locators are the same pieces for all those heads.

beanhead

Well-Known Member

And just a word of caution...I know everyone says they'll get their heads checked, and I know TF are some of the nicest OOTB quality-wise...but their spring specs as-tested do not match the paperwork specs. At least on the BB heads. So if you are buying check (or have your shop check) specifically the pressures and installed spring heights on every valve. It's more time for sure, and I guess it all depends on how nitpicky you are with this stuff but I found them all slightly different and they will need correcting. Not valve stem height but spring height which = pressure.

Okay so this thread was a month old...dammit!

Okay so this thread was a month old...dammit!

gzig5

Well-Known Member

So what kind of variation in pressure did you measure?? There’s variation in everything it’s just a matter of how much

beanhead

Well-Known Member

20-25 lb/in difference on the seat2s. The springs specs say 420 lb/in rate but they checked at just over 430. Tested seat pressures ranged from 160-180ish on springs that the paperwork says are 138 @ 1.95 installed height.So what kind of variation in pressure did you measure?? There’s variation in everything it’s just a matter of how much

Rolling_Thunder

Rolling Thunder

You can always get the bare heads without springs/retainers/locks and have a competent machine shop finish them off and install the appropriate springs for your cam. I ended up doing this with my TF heads - my machinist was really impressed with the castings and overall quality - he just touched up the valve seats to verify them, added springs and now they are on my engine.

I'm taking my new TF 190's to my machine shop tomorrow after noon. I'll have them checked and measured be fore we proceed with my short block. I appreciate your heads up on this possible glitch. Paul.

Excellent move to have a pro check it out and mike it up.

You would be disappointed in me if didn't. WWRD. What Would rumblefish Do? I respect your cam choices more than ever since I've done my research. I'm still learning from you. Next Subject: Camshaft degreeing , and rod selection at home.

Rod?

512Stroker

We are all here because we are not all there.

I questioned that when I read it too.Rod?

Push rods?

There ya go!

6.123 H or I beams. I liked the Mahle pistons, but my machinist told me their only about 9 lbs on the ring pack, not enough for a modern ring set for a 10:5 street/strip engine. The Molnar crank is on order, with the correct bearings. The block is being line bored, and set up for ARP studs and a windage tray. My Lunati 733 cam kit should be here in 3 weeks. Okay, Gentlemen, how much compression can I get away with using 92 Octane cat whizz gas and this big solid roller cam? rumblefish, Yellow Rose, and all others willing to chime in? I'll be happy to provide more specifics as the build moves on. I appreciate all positive input for my 408.

My bad. It's a 1998 5.9 Magnum 5.9. so I guess I'll need some Smith Brothers 3/8's hollow tubes for oiling, custom length. I've been getting great positive advice from members on this site. My A727 has been rebuilt for this motor, I'm shopping for a Torque converter for my 408. I sent out my spare 741 rear axle to be upgraded to a 3.91 Auburn SG, with rear discs included. I'm old and disabled, so this will likely be my last major build.

IF the 5.9 has head oil provisions (double check) you should skip the hollow tube pushrods. The engine can now oil the rockers in the normal fashion.

I run 93 on the wife’s 11.3-1 engine with a much smaller cam. Your good to go IMO.

I run 93 on the wife’s 11.3-1 engine with a much smaller cam. Your good to go IMO.

It's a 1998 5.9 block from a Jeep Grand Cherokee. Now that my TF 190's are there, I'll check them out with my machine shop. They drooled on them yesterday. Thanks, rumblefish, for your cam recommendations. My machinist is smiling every time we talk. Working on a set of 1 7/8's TTI's. I'll send you pic's, if you'd like. Please keep me in the loop with you're'73, and your old Yeller. Paul.

Connecting rod, of course. rumblefish said I should do them one at a time.Rod?

Scody21

Just send it

6.123 H or I beams. I liked the Mahle pistons, but my machinist told me their only about 9 lbs on the ring pack, not enough for a modern ring set for a 10:5 street/strip engine. The Molnar crank is on order, with the correct bearings. The block is being line bored, and set up for ARP studs and a windage tray. My Lunati 733 cam kit should be here in 3 weeks. Okay, Gentlemen, how much compression can I get away with using 92 Octane cat whizz gas and this big solid roller cam? rumblefish, Yellow Rose, and all others willing to chime in? I'll be happy to provide more specifics as the build moves on. I appreciate all positive input for my 408.

I’d not be afraid of running 12-1 on super clear non-ethanol with the TF heads. The higher the octane, the slower the gas burns... **** last summer my buddy was running 12-1 with X heads, ran great until a cam lobe went flat...

Yea! LOL! It’ll be hard to do them all at once.

rumblefish saved me again. I took my TF 190's to my machine shop yesterday. They were salivating, and asked me for permission to put them on their flow bench. Of course I said yes. Now we can select the rods and pistons for the build. I checked 4 chambers, and they were all 60cc. Once Lunati comes through with my solid roller cam and lifters, we can finalize the engine build.My machinist wants to go with a 10.3 compression ratio with my Voodoo cam. Covid has slowed all parts down, especially camshafts. No new blanks out there. I'm not backing down on my big cam selection. I'm old, and I want to do this build right. Thanks again to rumblefish. I took his advice.

Scody21

Just send it

Took 9 weeks for Howard’s to deliver a custom cam....

I'm passing on the Mahle pistons on the advice of my machinist. He informed me that the ring pack is light weight, only 9 pounds of tension on the rings. We're searching for a forged replacement in the 10.2-10.4 compression ratio to work with the cat piss 92 octane gas available at the pump for $4 a gallon.

I'm passing on the Mahle pistons on the advice of my machinist. He informed me that the ring pack is light weight, only 9 pounds of tension on the rings. We're searching for a forged replacement in the 10.2-10.4 compression ratio to work with the cat piss 92 octane gas available at the pump for $4 a gallon.

Buy different rings.

I hadn't thought of that. I guess I'm in the frame of mind where I want the components to match. I've watched your posts over the years, and I've come to respect your opinion. If you have time, maybe can can suggest a ring pack for the Mahle's. I like the fact they're lighter than most, to help with the reciprocating mass, and keep the use of mallory to a minimum.

-