Looking to see if anyone has experience installing the US Car Tool torque boxes and subframe connectors. My questions is, do you stitch weld the subframe connectors to the floor pan, or completely weld them? I think the torque boxes would get weld completely, but the subframe connectors would create a lot of heat to weld solid to the floor board. If anyone has experience with the install and or pictures, I would appreciate the insight.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

US Car Tool Torque Boxes and Sub Frame Connectors Install

- Thread starter 1967 Cuda

- Start date

-

Like you said, lot of heat. That is why you stitch weld it until you eventually do the whole thing.

Naturally remove the interior seats, carpet, padding etc.. and have an extinguisher handy.

Naturally remove the interior seats, carpet, padding etc.. and have an extinguisher handy.

Last edited:

I would also disconnect any electronics, Voltage regulator or ECU if you have EFI.

I recently found a welder (family friend) who is going to do my torque boxes at my house. I want to do sub frame connectors also, but we'll probably make our own instead of USCT's because I don't want to remove my whole interior. I'll be following along to see how your installation goes. Good luck!

Kendog 170

Let the boy go !

I bought rectangular stock when I did my 68 Dart. $20 at the time. Lined up well with the rear floor pan to plug weld. Also left space under the front floor pan for the E-brake cable to run over. I used a heavy gauge on my hardtop but went much lighter gauge on my ragtop that worked out well.

...and don't forget that there's a fuel line real close by

rklein383

Well-Known Member

- Joined

- Dec 2, 2005

- Messages

- 2,211

- Reaction score

- 1,803

I stich welded my subframe connectors in. Did 1" welds every few inches along both sides and fully welded the ends. The car stiffness is amazing now. I see no advantage of welding the entire length except for making you feel good.

What "bolt in" ones did you use. The OP is talking about US Car Tool connectors which are strictly weld in. I wish this was my car but it isn't.I've bolted them in an you can still feel the difference.

Kendog 170

Let the boy go !

Hellrats

Just another dumbass

What "bolt in" ones did you use. The OP is talking about US Car Tool connectors which are strictly weld in. I wish this was my car but it isn't.

Mancini Racing Bolt-In Frame Connectors

These can be bolted or welded in. I was just saying that because either way they really stiffen up the car. Of course welding will be better/stronger. Mine actually came in a Mopar Performance box. I think is was old stock though.

Last edited:

Hellrats

Just another dumbass

Fully welded or stitched is fine. I fully welded mine and seam sealed everything to keep moisture out.

Just make sure whenever you're reinforcing the chassis, that the suspension is carrying the weight of the vehicle when you weld them in. That will help to prevent unwanted flex. I've seen guys weld them in while on jack stands and the car had a "lean" to it and didnt drive straight.

I used my tall race ramps so that I could set the car on its weight, but I still had room to work and weld underneath.

Good luck. Chassis reinforcement is a good investment IMO.

Just make sure whenever you're reinforcing the chassis, that the suspension is carrying the weight of the vehicle when you weld them in. That will help to prevent unwanted flex. I've seen guys weld them in while on jack stands and the car had a "lean" to it and didnt drive straight.

I used my tall race ramps so that I could set the car on its weight, but I still had room to work and weld underneath.

Good luck. Chassis reinforcement is a good investment IMO.

Maxjax. Lift height is 48"What lift do you have in the picture? How high does it go?

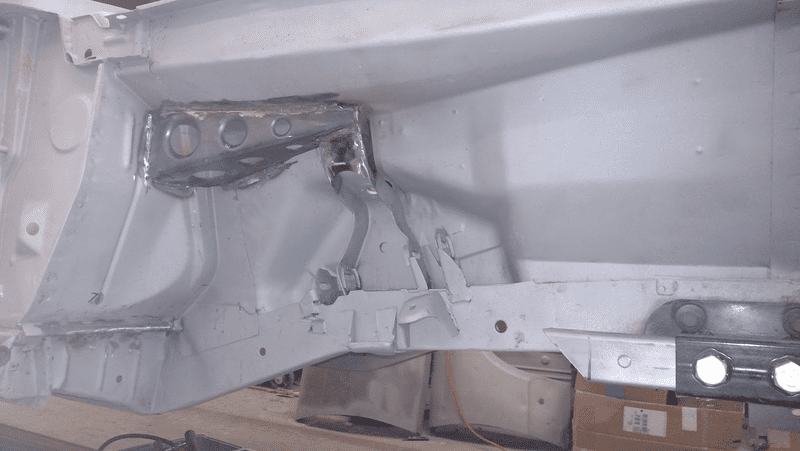

You may have to "tweak" the torque boxes to get a nice install. I had to cut and weld a bit to get them to fit right.

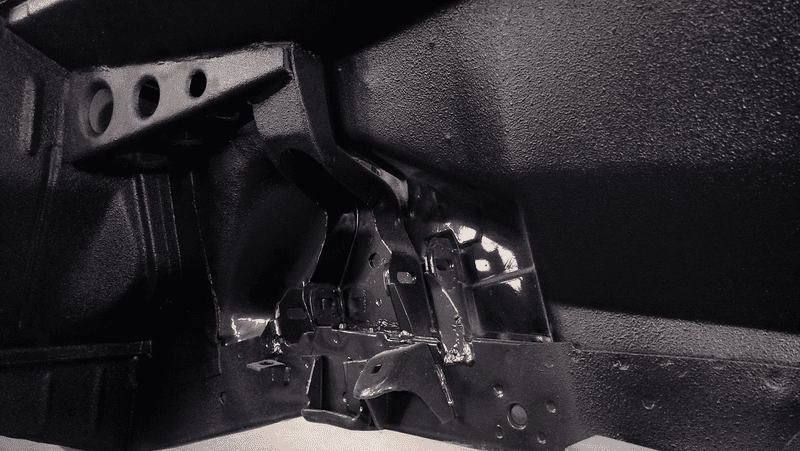

I had the USCT frame connectors installed. I think my installer stitch welded them in then we seam sealed them to the body before undercoating.

They butt right up to where the fuel line attaches and they occupy space where the fuel line crosses. I also had to relocate my e-brake tensioner/anchor rod. We ended up rerouting the fuel line which means we had to re-bend the new SS lines I bought. If I could do it over, I would notch the connectors to allow the fuel line to remain in the factory location.

Best pic I could find for now.This is before we reworked and installed the fuel and vapor line.

They butt right up to where the fuel line attaches and they occupy space where the fuel line crosses. I also had to relocate my e-brake tensioner/anchor rod. We ended up rerouting the fuel line which means we had to re-bend the new SS lines I bought. If I could do it over, I would notch the connectors to allow the fuel line to remain in the factory location.

Best pic I could find for now.This is before we reworked and installed the fuel and vapor line.

64mopar64

Active Member

Sorry for the long post, hope it's helpful.

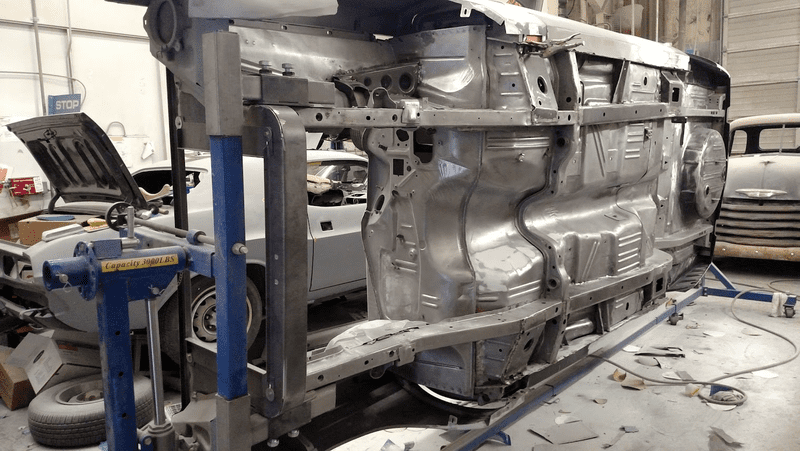

I just finished installing USCT subframe connectors and torque boxes 5 days ago. Installation was done with the car completely disassembled and mounted on a rotisserie. I can weld but I'm not a welder if you know what I mean. Earlier this year we installed the same components in my sons 69. The 69 was on a lift, it still had glass, doors, trunk, hood but mechanicals and interior were completely removed. A freind of my sons who is a professional welder did the welding.

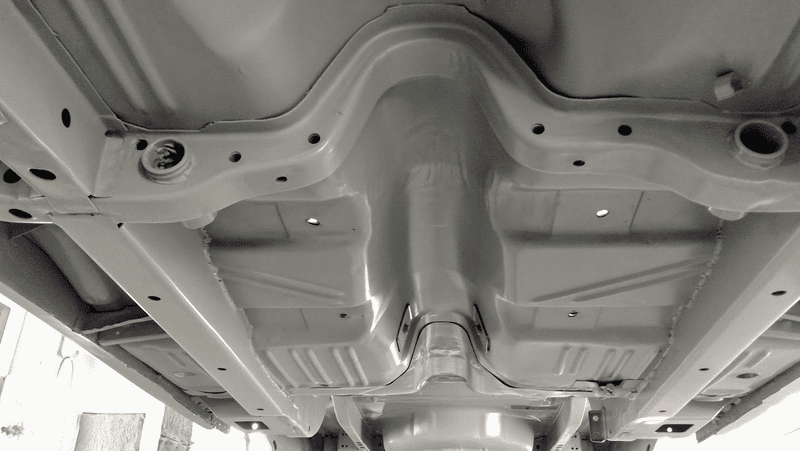

Welding the subframe connectors to the floor pan (thick to thin) is the most difficult part. The floor pan gets even thinner at the crowns of bends and beads. Avoiding welding on bends and beads will reduce burn through a lot. Welding on the rotisserie is much easier because the the car could be positioned with thick metal above the thin metal thereby acting as a heat sink drawing the heat from the thin stuff. In that case a continuous bead could be run by keeping the weld bead on the thick and quickly rolling it onto the thin then back to the thick. About 80% of the floor to frame connector is welded however IMO stitching were the floor pan is flat and accessable should be more than adequate. Sold weld all accessable areas where the frame connector contacts front and rear frame. On both mine and my sons a dutchman was required between the verticle portion of the frame connector and the transmission support

My advice is start with tacks and see if you can progress to small stiches. If you can't connecting tacks will work.

Practice positioning your head and mig gun a couple times (for each little area) before pulling the trigger, it's very easy to have a lot more stick out than you intended producing bird poop weld and burn through

Trim connectors to fit as close as possible before welding.

Take your time, if you get tired come back tomorrow.

The torque boxes are a lot easier. Continuous beads at frame rails, rockers, and frame to rocker supports and tacks or stiches where the front torque boxes contact the floor. There is a space between the front leaf spring mount and the back of the frame connectors. Plan for that, I chose to fill the are with another plate before installing the torque box. As CFD244 stated, some fitting required for front torque boxes including bending the torque box and bending the flange on the frame rail to rocker connector.

I just finished installing USCT subframe connectors and torque boxes 5 days ago. Installation was done with the car completely disassembled and mounted on a rotisserie. I can weld but I'm not a welder if you know what I mean. Earlier this year we installed the same components in my sons 69. The 69 was on a lift, it still had glass, doors, trunk, hood but mechanicals and interior were completely removed. A freind of my sons who is a professional welder did the welding.

Welding the subframe connectors to the floor pan (thick to thin) is the most difficult part. The floor pan gets even thinner at the crowns of bends and beads. Avoiding welding on bends and beads will reduce burn through a lot. Welding on the rotisserie is much easier because the the car could be positioned with thick metal above the thin metal thereby acting as a heat sink drawing the heat from the thin stuff. In that case a continuous bead could be run by keeping the weld bead on the thick and quickly rolling it onto the thin then back to the thick. About 80% of the floor to frame connector is welded however IMO stitching were the floor pan is flat and accessable should be more than adequate. Sold weld all accessable areas where the frame connector contacts front and rear frame. On both mine and my sons a dutchman was required between the verticle portion of the frame connector and the transmission support

My advice is start with tacks and see if you can progress to small stiches. If you can't connecting tacks will work.

Practice positioning your head and mig gun a couple times (for each little area) before pulling the trigger, it's very easy to have a lot more stick out than you intended producing bird poop weld and burn through

Trim connectors to fit as close as possible before welding.

Take your time, if you get tired come back tomorrow.

The torque boxes are a lot easier. Continuous beads at frame rails, rockers, and frame to rocker supports and tacks or stiches where the front torque boxes contact the floor. There is a space between the front leaf spring mount and the back of the frame connectors. Plan for that, I chose to fill the are with another plate before installing the torque box. As CFD244 stated, some fitting required for front torque boxes including bending the torque box and bending the flange on the frame rail to rocker connector.

'Cuda_ragtop

Woulda, Shoulda, 'Cuda!

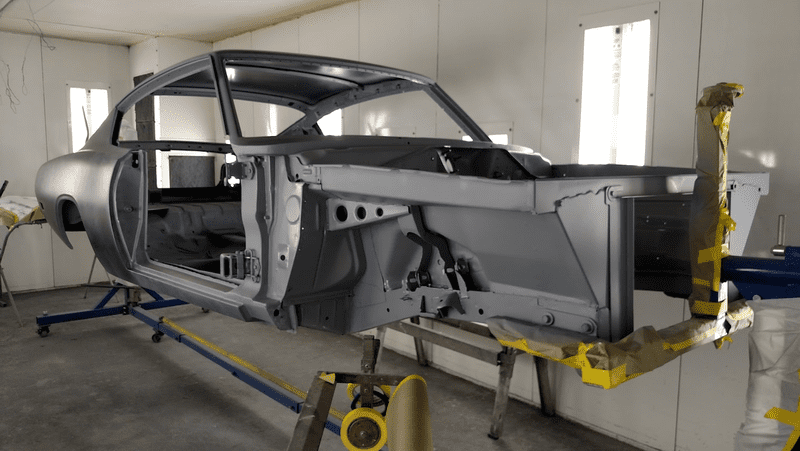

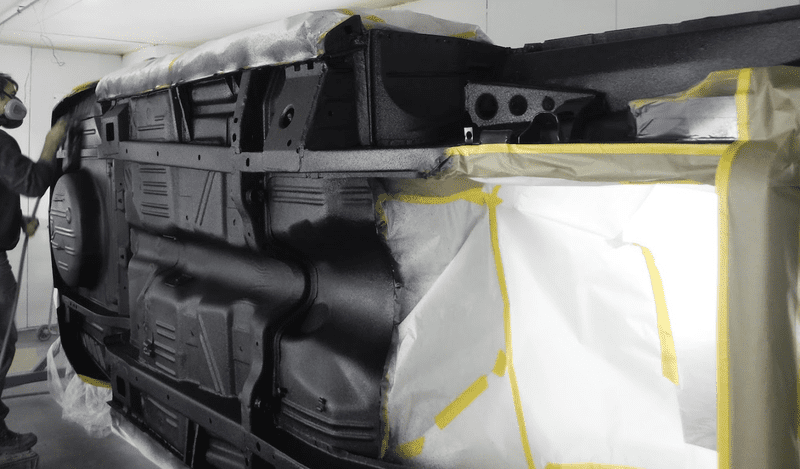

Fully welded, epoxy primed, seam sealed then U-pol Raptor bedliner.

USCT - Full radiator core support w/26" opening, inner fender and shock tower braces, torque boxes and frame connectors.

Now you can lift the car by any corner and see very little flex. She is stiff!

Full Core support, inner fender braces + braced and boxed shock towers.

Showing how we kept some body color and bed lined the rest.

Lots of ways to make improvements, this just how we decided to go.

USCT - Full radiator core support w/26" opening, inner fender and shock tower braces, torque boxes and frame connectors.

Now you can lift the car by any corner and see very little flex. She is stiff!

Full Core support, inner fender braces + braced and boxed shock towers.

Showing how we kept some body color and bed lined the rest.

Lots of ways to make improvements, this just how we decided to go.

340sFastback

Well-Known Member

I tacked mine to the floor with a tack every 1/4 inch or so. Fully welded front and rear frame rails. I ran panel bond over the seams to seal them then epoxy primed.

Thanks everyone for all of the info and picture! On my dad's 68 Coronet we used the square tubing style so it was little different and that was year ago. I have the full core support and the inner fender braces and boxed shock towers as I'm going to be running coilovers in the front instead of torsion bars. Car is sitting on the wheels now and has no interior, or fuel system, so I should be good there. Here are a few pics of where I am at to this point.

Both have been OOS for years it seems like and will never become available again.

have the USCT connectors on 2 of my 1970 Darts. you are trying to make a box beam using the floor as the third side. The more completely it is welded to the floor the more effective the connectors will be. This set up made an enormous difference in both of the cars! 53 years of driving them had made the cars kind of 'flexible' and this really stiffened them up.

Rbob

Well-Known Member

I stitch welded completely to avoid excess heat on a rotisserie, ran the e-brake cable thru the subframe by drilling holes where the cable naturally crossed the subframe and used a big pry bar to make the holes fit better and rerouted gas line. There was a gap for the fuel line to cross over.

-