Figured I’d layout my information since I took a lot from this thread. My car is a 74 Dart sport that had an 8 1/4 rear in it originally. I got a 3L73 off craigslist in good shape the guy who sold it also just cut the driveshaft off so I had the original shaft flange yoke from the explorer. I grinded and sanded off all the mounting tabs and got $15 spring perched for an 8 3/4 and opened them up a little to fit over the 8.8. Before I ripped out my 8.25 I measured pinion angle and matched it with my new 8.8. I was able to use two drivers side emergency brake cables and they worked out perfectly and mated up to my emergency brake split cables that were original to the car. I didn’t have to cut my rear end at all! It makes the rear approx 3” wider overall and I just took it for a text drive and didn’t get any vibrations in the driveshaft or anything. I run 275/60/15 with 4.5” backspacing American racing torq thrust wheels. I have a little over an inch clearance to my leaf springs. I used a moog 457 u joint and my Driveshaft fits great. I’m posting this info for all the folks with dart sports and dusters out there wondering if you don’t have to cut it and honestly I wouldn’t cut the axle unless your mini tubbing. My car with the 373 gears is at 65 mph at 3000 rpms on the hwy wish I had another gear but that’s another project for another time. Any questions just ask. -Nate

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

8.8 swap

- Thread starter dart360swinger

- Start date

-

moparmat2000

Well-Known Member

Figured I’d layout my information since I took a lot from this thread. My car is a 74 Dart sport that had an 8 1/4 rear in it originally. I got a 3L73 off craigslist in good shape the guy who sold it also just cut the driveshaft off so I had the original shaft flange yoke from the explorer. I grinded and sanded off all the mounting tabs and got $15 spring perched for an 8 3/4 and opened them up a little to fit over the 8.8. Before I ripped out my 8.25 I measured pinion angle and matched it with my new 8.8. I was able to use two drivers side emergency brake cables and they worked out perfectly and mated up to my emergency brake split cables that were original to the car. I didn’t have to cut my rear end at all! It makes the rear approx 3” wider overall and I just took it for a text drive and didn’t get any vibrations in the driveshaft or anything. I run 275/60/15 with 4.5” backspacing American racing torq thrust wheels. I have a little over an inch clearance to my leaf springs. I used a moog 457 u joint and my Driveshaft fits great. I’m posting this info for all the folks with dart sports and dusters out there wondering if you don’t have to cut it and honestly I wouldn’t cut the axle unless your mini tubbing. My car with the 373 gears is at 65 mph at 3000 rpms on the hwy wish I had another gear but that’s another project for another time. Any questions just ask. -Nate

Sounds great. Add an A518 O/D with those 275 60s and drop your final drive RPMs to 2,100 @65

Oldiron440

Well-Known Member

I'm doing this swap in a Ford project of mine and did it a little differently. I had Quick performance in Ames Ia cut the ends off and put 9" billet ends on so I could use there axles. The Ford axles are c clips and there are no eliminator kits for them. I also had the tudes welded to the case, all this for $600. I live 90 miles from Ames so I was able to drop it off and pick it up two days later. It help that I had the housing stripped down and sandblasted along with washed.

Edit: I'm going to add that the work Quick performance did was top notch with beautiful welds. I've used there axel assembly's for projects I've done for others but this was the first time on one of my own.

Edit: I'm going to add that the work Quick performance did was top notch with beautiful welds. I've used there axel assembly's for projects I've done for others but this was the first time on one of my own.

Last edited:

moparmat2000

Well-Known Member

I kinda like the fact that its shortened to close to stock width for my kids car. 69 barracuda. 67-69 barracuda uses same inner and outer wheel houses as a duster. But I wanted mine narrowed to close to stock width, and the pumpkin more centered.

Last edited:

I agree By not shortening it the drive line angle is that much more offset. But I have noticed there have been plenty who haven’t shortened the 27/8” and haven’t any problems. I shortened mine and used the 1/2” doctor diff offset shackles. I can fit 5” of backspace easily, i recently picked up 15x9 cop wheels with a 4.5” backspace that I plan to run the nitto’s 295/55/15’s they should fit perfect. My picture shows 6” from mounting service to the spring. I like to leave at least an 1” of space between the tire and the spring to include the inner tub for tire clearance.I kinda like the fact that its shortened to close to stock width for my kids car. 69 barracuda. 67-69 barracuda uses same inner as nd outer wheel houses as s duster. But I wanted mine narrowed to close to stock width, and the pumpkin more centered.

moparmat2000

Well-Known Member

Just going to run 7" fifth ave steelies. Good to know a 15x9 with right offset will fit under there. 15x8 is as daring as I will go.

clair.davis

catching up...

Figured I’d layout my information since I took a lot from this thread. My car is a 74 Dart sport that had an 8 1/4 rear in it originally. I got a 3L73 off craigslist in good shape the guy who sold it also just cut the driveshaft off so I had the original shaft flange yoke from the explorer. I grinded and sanded off all the mounting tabs and got $15 spring perched for an 8 3/4 and opened them up a little to fit over the 8.8. Before I ripped out my 8.25 I measured pinion angle and matched it with my new 8.8. I was able to use two drivers side emergency brake cables and they worked out perfectly and mated up to my emergency brake split cables that were original to the car. I didn’t have to cut my rear end at all! It makes the rear approx 3” wider overall and I just took it for a text drive and didn’t get any vibrations in the driveshaft or anything. I run 275/60/15 with 4.5” backspacing American racing torq thrust wheels. I have a little over an inch clearance to my leaf springs. I used a moog 457 u joint and my Driveshaft fits great. I’m posting this info for all the folks with dart sports and dusters out there wondering if you don’t have to cut it and honestly I wouldn’t cut the axle unless your mini tubbing. My car with the 373 gears is at 65 mph at 3000 rpms on the hwy wish I had another gear but that’s another project for another time. Any questions just ask. -Nate

This is great info! Do you happen to know what year the Explorer was? Betting my 69 Valiant is real close to a Dart.

dartfreak75

Restore it, Dont part it!

This is the video I went by kinda lengthy but well worth the watch!!! He explains everything in detail...there’s 2 parts to his video series on the 8.8 the first is about the tear down another one worth watching as well...esp if you’ve never broke down an 8.8 internals!

Hope this helps!!!

Man i have watched this video at least three times and still cut the inside edge before the outside!

dartfreak75

Restore it, Dont part it!

I like that that does give it a sleeker cleaner look. Love the plug idea I saw that on hear a while back but didnt realize it was you that posted it I'm gonna do that for sure! I actually have a Ford tube vent somewhere if I can find it I bought it from napa for my truck when I replaced all the brake lines and hoses and they gave me the wrong one so I had to order a mopar one. I never took it back so its probably in my tool box if I can find it!Cut the stupid looking "ears" off. Wire wheeled the general area around it with an aggressive wire wheel to rid it of scale rust and dirt, then a quick shot of rustoleum primer. Looking much better IHMO. I will probably leave the one strengthening rib on the left side, but may still cut and grind off that nub sticking out on the lower corner on the left side.

View attachment 1715227395

View attachment 1715227396

View attachment 1715227397

View attachment 1715227419

View attachment 1715227420

moparmat2000

Well-Known Member

Well got my pinion out. Had to use an aluminum plate and mini sledge to knock it out. Put plywood under it to catch it. It was frozen onto the fwd pinion bearing inner race. I bought a Yukon gear crush sleeve eliminator kit. Looks very well make IMHO. I figure that's the best way to fly on this. My crush sleeve that came out of the rear measured out at .451". The eliminator kit came with a lot of different thickness shims. Without the shims added inside the 2 halves of the eliminator it measured .426" . So I had to make a shim stack to bring total thickness back up to .451" . I was able to mix n match and get it to .452". Not sure what that extra .001" is going to do for my pinion depth and contact pattern, but it's a start for setting it up. I got a ways to go before this. Need to pull the outer races out, along with the axle bearings, and give the housing a good cleaning first.

moparmat2000

Well-Known Member

Needed a bearing puller for the 8.8 axle tube bearings. A bearing puller slide hammer kit was $75 at harbor freight. I already had a slide hammer for my autobody stud puller kit. Being a cheap ***, i decided to make an attachment for the one I currently have. Cost me $1.07 for the metric nuts, and about 30 minutes time. I never throw away little scraps from other projects so I had just the piece to weld on. This will also work on GM 10 and 12 bolt rears.

slick tool you made. I just borrowed one from O’riellys tool loaner program.

Alex69Dart

Active Member

Can someone please post flange to flange measurements on their 8.8 swap? My understanding is that Mopar rear ends for the Dart never exceeded 51.6' flange to flange. I have an 8.8 that I'm putting 9" axle ends on and Im curious what flange to flange measurements will fit. I already have 10 inch rims for the car I will be running. Thank You in advance!

moparmat2000

Well-Known Member

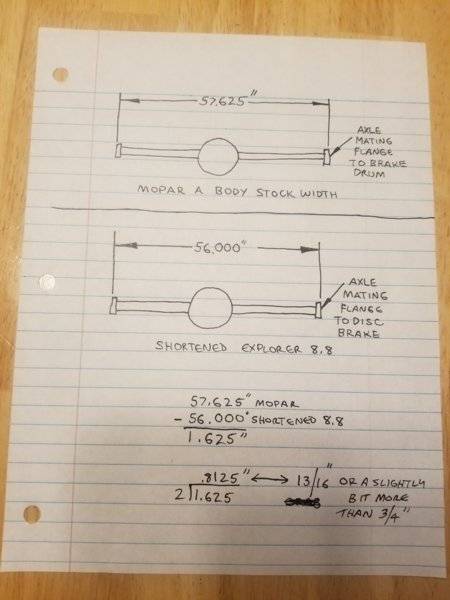

I think this is what your looking for. Basically the 8.8 disc brake rear when narrowed is about 3/4" narrower per side than the mopar A body 8.75" axle. The drawing is based on drum or disk to rim mating surface dimensions, and not bearing flange dimensions.

Last edited:

Alex69Dart

Active Member

I’m trying to figure out how much I need to shorten if I have too at all. This does help a bit as now I can figure out what I haveI think this is what your looking for. Basically the 8.8 disc brake rear when narrowed is about 3/4" narrower per side than the mopar A body 8.75" axle. The drawing is based on drum or disk to rim mating surface dimensions, and not bearing flange dimensions.

View attachment 1715446439

moparmat2000

Well-Known Member

To center the pumpkin you remove approximately 2&7/8" from the left side axle tube, and install a second right side axle into the left side. The measurements in the diagram above is with the left side tube already shortened 2&7/8" to center the pumpkin making it approx 3/4" narrower on each end compared to an 8.75"

jrlegacy23

68 Barracuda

The stock 66-72 A-body stock rear is 57 1/8" wide. Plus, with the 8.8 you wind up with 56 1/2" from WMS to WMS when you cut down a Ford Explorer disc brake rear.

I think this is what your looking for. Basically the 8.8 disc brake rear when narrowed is about 3/4" narrower per side than the mopar A body 8.75" axle. The drawing is based on drum or disk to rim mating surface dimensions, and not bearing flange dimensions.

View attachment 1715446439

moparmat2000

Well-Known Member

I fudged my numbers w a tape measure. Figured I got em close enough.

moparmat2000

Well-Known Member

Closer to building up my ring gear carrier with new parts. I cut the old bearings off. Inner races I will use as press tools to help install the new ones. Took the opportunity to clean off some pretty rough casting flash. Hoping this helps strengthen it a little bit anyways by removing the stress risers in the casting.

moparmat2000

Well-Known Member

Bearing pressing day during lunchbreak. I kept the old inner races as tools to seat the new bearings.

jrlegacy23

68 Barracuda

I did the same on my last 8.8 swap. I had a hard time putting the center section back in. Not sure if the housing "squeezed" a bit from not have the diff unit in it for a few days. It dropped in about 75% of the way and I pretty much beat it in with a dead blow and 2x4 the rest of the way.

moparmat2000

Well-Known Member

I have a center housing spreader

jrlegacy23

68 Barracuda

I didn'tI have a center housing spreader

Alex69Dart

Active Member

I’m gonna be running a 9 inch set up for my rear end. 9 inch axle ends. Gonna take the rear end to a fab shop. Car doesn’t move for now so I’m trying to get measurements to the fab shop. Gonna go try my hand at measuring.

jrlegacy23

68 Barracuda

I’m gonna be running a 9 inch set up for my rear end. 9 inch axle ends. Gonna take the rear end to a fab shop. Car doesn’t move for now so I’m trying to get measurements to the fab shop. Gonna go try my hand at measuring.

Get the wheels that you want to run first. Then, set them in place and measure backside to backside.

-