I hate how hot it is out but the epoxy loves it.... a few hours in the Az heat and sun and the epoxy is hard as a rock..... Parchment paper is your friend as the epoxy won't stick to it. Sanded and a bit of glaze to make it perfect. I plan on a session outside with the blaster and glass beads next weekend to get it ready for paint.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

1963 Dodge Dart 270 Convertible for the Wife

- Thread starter Jim Kueneman

- Start date

-

Bit of a whiskey spending spree on eBay last weekend but lots on NOS stuff that will fit and look right..... Rear panels for the convertible top are bead blasted and the first coat of paint... Need to sand out some flaws then hit it with the finish coat with a bit of flattener in it to kill the shine. Transmission is cleaned ready for clear coat. Picked up the interior and it looks great... @billccm

Looks darn good and I am impressed, especially watching others spend $$$$$$$$ like a drunken sailor!!!! LOL

Every time I drag home a new project, the wife asks everyday, so what is the mail carrier, UPS and/or Fed X driver bring today!!????? lol

Every time I drag home a new project, the wife asks everyday, so what is the mail carrier, UPS and/or Fed X driver bring today!!????? lol

Looks darn good and I am impressed, especially watching others spend $$$$$$$$ like a drunken sailor!!!! LOL

Every time I drag home a new project, the wife asks everyday, so what is the mail carrier, UPS and/or Fed X driver bring today!!????? lol

I just got done with a messenger chat with my A-Body drug dealer.... I thought he was not interested in selling but he still has the '72 Demon 340 4 speed car and the '68 Barracuda 318 ragtop car and was teasing me I could own them both........

Difficult painting between the rain drops but the rear panels are painted.... There should be an upper cap that a guy in Florida is making (same guy made the white caps). Once he has them figured out and I have one another round of painting and time to bolts this all in for the last time. Should the arm rests be recovered in white or turquoise? The front replacements I have are white....

View attachment 1715587099

View attachment 1715587099

69_340_GTS

Well-Known Member

It all looks great! I vote for white.

mygasser

Well-Known Member

even before i read the fronts are white i thought 'white'.

neil.

neil.

Dang Jim, you have a lot of patience with the stinking hot weather & all of the little knick knack things you have to do. I'm positive that it will turn out to be a stunner as your other two cars are.

Looks like I will be old news at the HEMI show in Phoenix next spring

Looks like I will be old news at the HEMI show in Phoenix next spring

Jim, WOW! Car is gorgeous! Gives me hope and motivation that I can get mine to look half as good someday. Cool video.

Dartsun

Mopar Dude

Looks like I will be old news at the HEMI show in Phoenix next spring

That one is a nice 64, but to me 63 is more rare and yours looks fantastic Jim. Dustin

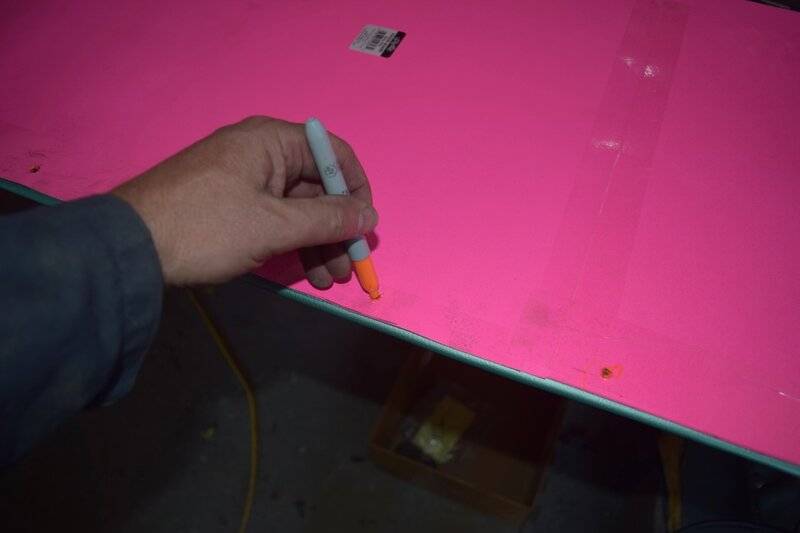

Well I messed up.. I forgot the door panels had been redone and they were too large... With the new seals and trying to pinch the door panel between the door and the seal was a no go so I had to reshape the door panels.... The right side came out perfect so here is the process... Step one make a nice template. Pull the staples and peal back the vinyl. Layout the template and use a Dremel oscillating saw to cut the backing board... Make sure you have the vinyl separated far enough.... DAP is the only contact adhesive that I think is worth a damn. Fold her back up and that part is done.

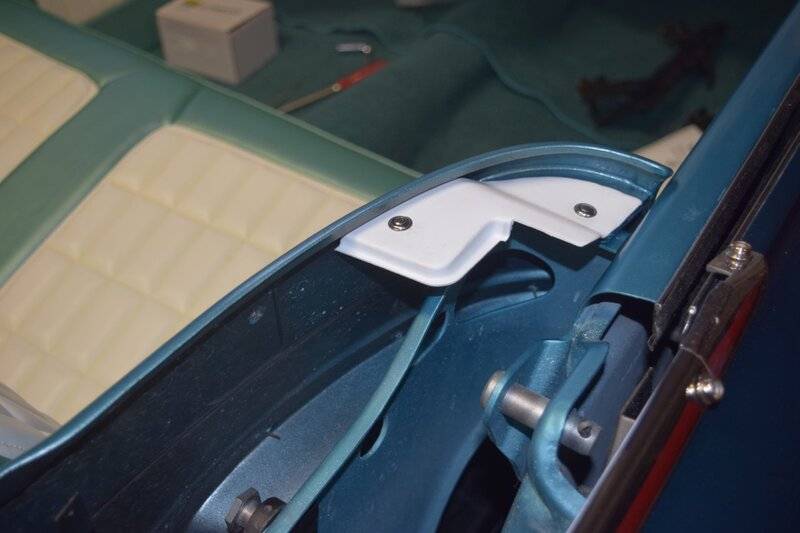

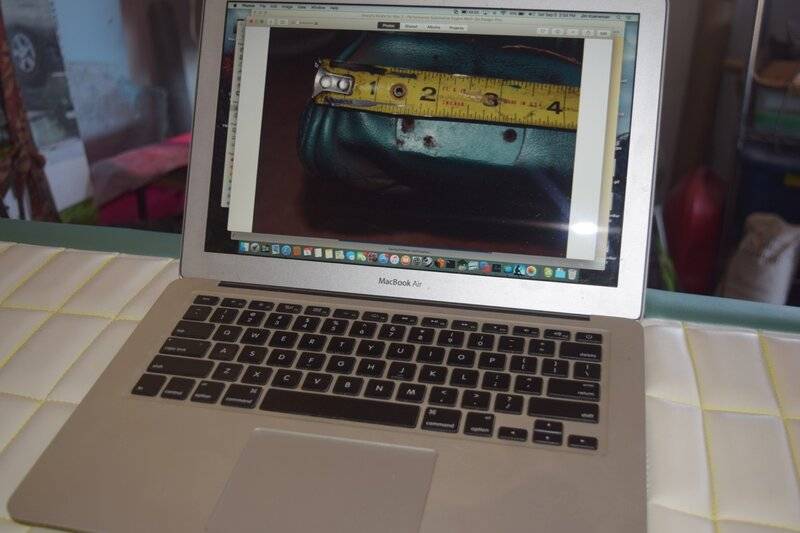

Front side can't tell I did anything. Now mark for the clips. Position and mark the back edge. Use a Dremel with flat bottom bit. You can tell when it goes through the backer board and into the foam sheet. Put you fingers under so you can feel it you are touching the backside of the vinyl. Slip the new clip in and position it over the dot.

All done. Align the clips with it on the door so they are going in straight.. Perfect fit. Paint up the trim on the seats and start assembling. Smart man takes lots of photos.... I would not never remembered where those big springs clipped to or where the holes were for the brackets.

Bit more assembly and you can sit in the old girl!

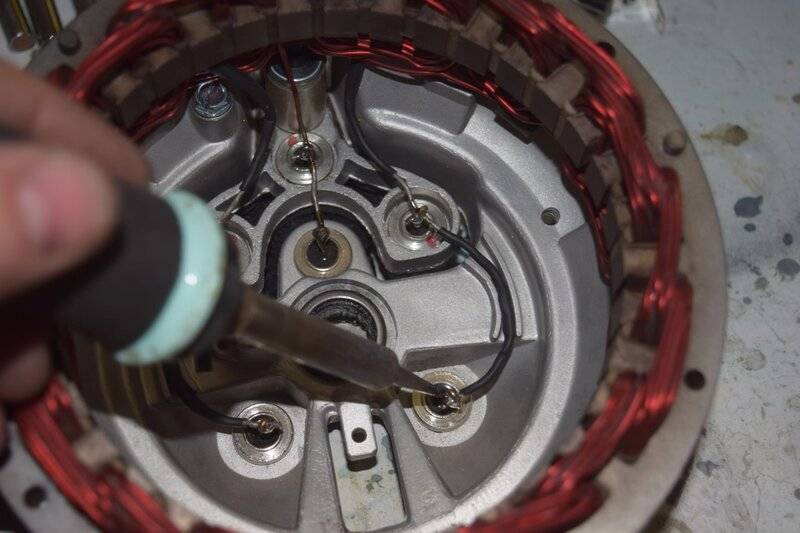

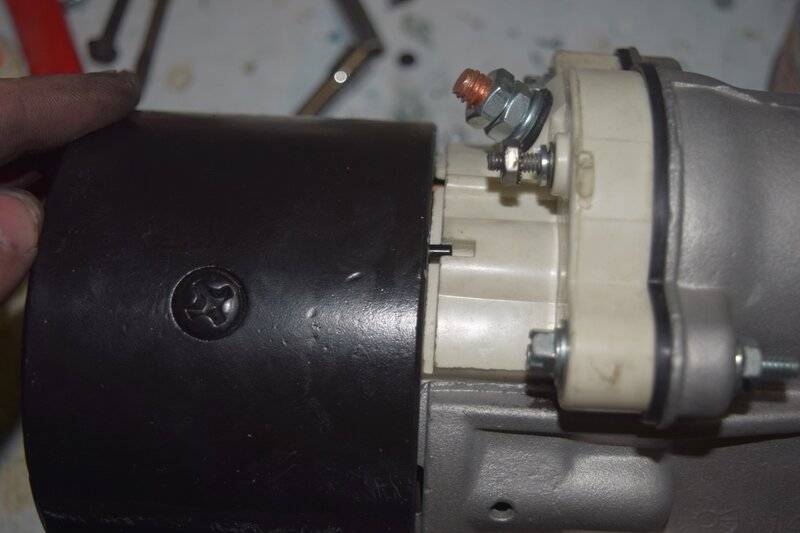

We started these last year sometime and got distracted.... Time to assemble... Make sure the positive diode carrier is isolated from the main chassis... Notice you can have the carrier twisted far enough to shot out, make sure it is centered... My buddy at the machine shop pressed the diodes and pulley on for me already. These old round backs you need to be very careful that the 3 field wires coming in out ring are not shorted (notice the heat shrink tubing) and they are tucked back far enough that the stator does not hit them when it spins. I had to make a few adjustments as the center wire is very short on this one... The fan blades on the stator was hitting it.

In go the brushes and we are done... I bead blasted and clear coated the wire clip later in the day...

Next unfinished project...... The main thing here is I bought a quality set of snap ring pliers as when I was trying to get the shaft snap ring on I blew a gasket and tossed it in the box.... Took all of 9 seconds to put it on with good tools... I have fought that snap ring on the other cars for 10 minutes with crap tools....

This brush holder keeps the brushes in place and when the armature is pushed in it just gets pushed in and stays in there forever. Neat design I think... You have to have the armature in the housing before you insert it in the brushes. The housing won't go over the armature from the back end.

Snap on the cover and use the battery charger to test her out. Spins up nicely. Ready to start the SL6. What the heck I was dirty so I started on the last big project... I know why this thing would not go over 30mph when I got it. I had to pound the upper part of the shaft off.. It as not advancing at all, all jammed up.. Took a lot of sandpaper on the shaft to get it to work freely. Installed FBO springs and plate at 10 degrees. With 14 degrees initial timing the plate will limit it to (10 * 2 = 20 crankshaft degrees) so 14+20 =34 degrees of mechanical advance should be perfect. Need to get a new vacuum advance though.. seems like it is not working... I need a new Snap-On hand vacuum pump.... Got beat up with the heat in the garage and called it a day.

I have been accumulating OEM bolts/nuts/tidbits over the last year for under the hood as most of them where not original and not right so today was clean and get the drivetrain hardware ready... I have a short list of bolts and nuts I need to find better version of but for the most part everything is ready. The one old motor mount was fine threads so they used a steering linkage castle nut.... good grief....

The only major greasy project left is the reseal the steering gear!

-