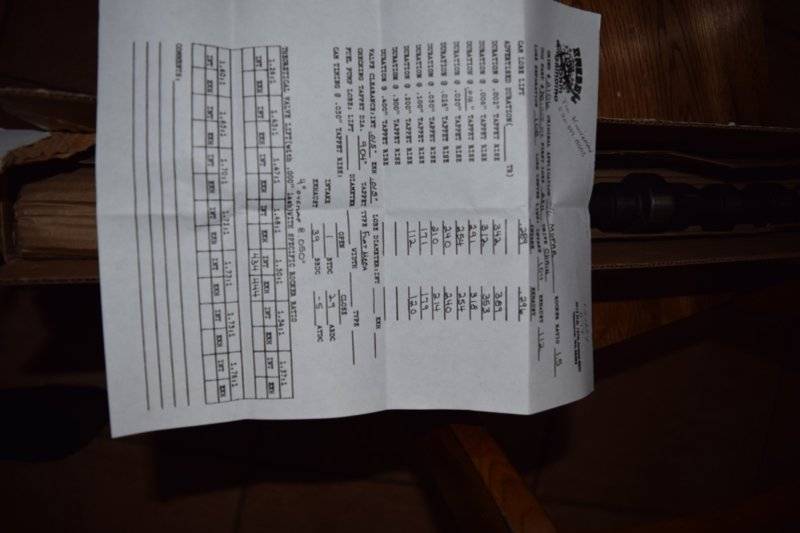

Got my custom grind RV15RDP (designed by Doug Dutra) today from Oregon Cam Grinding.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

1963 Dodge Dart 270 Convertible for the Wife

- Thread starter Jim Kueneman

- Start date

-

I have 2 cams I need to send them.

I have 2 cams I need to send them.

I opted for a new one. He could have reground the original as well

Gonna be a less than spectacular weekend on the Dart. I helped a friend at is first chuckwagon cook off with is new chuck wagon at the local ranch and rodeo days today. Cooking for 50+ hungry cowboys kicked my a$$.

Well I spent last night looking up chuck wagons and how hard it would be to restore one..... Today back to reality....

Here is my coal slag blast station. Blasted out the places I needed to weld and the wheel well lip. I have decided I am going to put a cut in the panel so I can pull the lip out further to blast it completely. It is sort of blasted but if I did all this work it would be stupid to only get it half a$$ed blasted before the epoxy primer.

All blasted. I think blasting the whole car like this is not going to be difficult at all.

Swiss cheese appeared after blasting it.

So-so blasting. Like I said need to cut the quarter to allow this to pull out further to blast it better than weld up the cuts..

Going green. Recycled the blast media by running it through a wire mesh.

Need to make a patch here.

A little plate steel I bought for the Coronet and used on the Duster and now the Dart forms a custom repair. I am not looking for style points here just a solid patch.

All done.

I clamped the patch on the outside of the panel and used the o-ring pick to scratch where I need to cut the patch panel. Glad I did not cut it today as when I sanded off some of the bondo I found a patch brazed in above were I was going to cut the patch. Need to add another 1" of patch area to the quarter by the taillight.

Just clamped over the quarter to mark it.

Here is my coal slag blast station. Blasted out the places I needed to weld and the wheel well lip. I have decided I am going to put a cut in the panel so I can pull the lip out further to blast it completely. It is sort of blasted but if I did all this work it would be stupid to only get it half a$$ed blasted before the epoxy primer.

All blasted. I think blasting the whole car like this is not going to be difficult at all.

Swiss cheese appeared after blasting it.

So-so blasting. Like I said need to cut the quarter to allow this to pull out further to blast it better than weld up the cuts..

Going green. Recycled the blast media by running it through a wire mesh.

Need to make a patch here.

A little plate steel I bought for the Coronet and used on the Duster and now the Dart forms a custom repair. I am not looking for style points here just a solid patch.

All done.

I clamped the patch on the outside of the panel and used the o-ring pick to scratch where I need to cut the patch panel. Glad I did not cut it today as when I sanded off some of the bondo I found a patch brazed in above were I was going to cut the patch. Need to add another 1" of patch area to the quarter by the taillight.

Just clamped over the quarter to mark it.

Not a lot of photos of the welding of the modified Duster trunk extension patch. It is not beautiful but it is solid. Need to get the blaster out once more and blast the welds to get the welding contaminates out then epoxy primer it before cutting and installing the outer panel patch.

So you are using thd bucket siphon type blaster? I have looked at them but was not sure how practical they are doing our cars.

So you are using thd bucket siphon type blaster? I have looked at them but was not sure how practical they are doing our cars.

I stole this out of the Harbor Crap cabinet. It actually work WAY better than I was expecting. I need to get about 6' of 5/8" heater hose so I don't need the bucket so close but it worked great, especially with the new air dryer. I blasted part of the rear undercarriage just for fun. I think I will have the wife hit the underbody with the 90 degree air tool with 50 grit on the flat surfaces and with this gun I am sure I can knock out the rest easily in a day.

You have to have filtered media so it won't plug the gun. I was looking at the expensive guns ($300+) but after today I am going to give the Harbor Crap gun a chance. I use to use Aircraft strippers but the new "safe" formula sucks.

Last edited:

Spot weld drilling by moonlight.... There was a bit more old restoration work on the drivers side than I would have guessed. This restoration was probably done sometime in the early 80's if I had to guess. It looks so similar to the Coronet that had a refresh in the late '70s.

At least on this side the extension is solid. It will have a bit of swiss cheezing but that is fine. I should just buy the damn patch panels for the wheel lip and lower quarter for both sides and stop being afraid of welding.

I also have my Southern Polyurethane on tonight!

At least on this side the extension is solid. It will have a bit of swiss cheezing but that is fine. I should just buy the damn patch panels for the wheel lip and lower quarter for both sides and stop being afraid of welding.

I also have my Southern Polyurethane on tonight!

Done a glass of whiskey and a push of a button and the wheel opening quarter patches are on order. Now I can just cut the crap out and blast the inner fender tub like I should and have a solid car that will last another 50 years.

Guess where I am going to cut it to install..... body line so it will be easy to blend in.

Guess where I am going to cut it to install..... body line so it will be easy to blend in.

Emailed Frank and the dash plastic was going into plating today! The quarter patches will be here tomorrow. Friday off. Taking the daughter with the Duster to get her license Friday afternoon, and the wife is ready to work so there should be serious progress this weekend.

Got up early and got with it......

This is the workhorse to get 90% of the rust off....

Then I set it up in my high tech sandblasting booth....

After that hang it from the high tech parts holding and hit it with SPI black epoxy primer...

Then hang the rest of the parts that we blasted over the last few weeks and another quart of SPI epoxy..

Gonna be one fine '63 Dart in a few months...

Got this done too, ready for grey SPI primer tomorrow...

Took the youngest to DMV at 1:00 and she can now drive the Duster alone...... Not sure I like that or not.

Picked up the K-Frame from the engine shop. He hot tanked it for me need to blast it in the morning. He also restored the upper control arms, bead blasted, painted and new ball joint and bushings. He still has the lowers and the /6.

We are going to have to work around afternoon thunder showers all weekend....

This is the workhorse to get 90% of the rust off....

Then I set it up in my high tech sandblasting booth....

After that hang it from the high tech parts holding and hit it with SPI black epoxy primer...

Then hang the rest of the parts that we blasted over the last few weeks and another quart of SPI epoxy..

Gonna be one fine '63 Dart in a few months...

Got this done too, ready for grey SPI primer tomorrow...

Took the youngest to DMV at 1:00 and she can now drive the Duster alone...... Not sure I like that or not.

Picked up the K-Frame from the engine shop. He hot tanked it for me need to blast it in the morning. He also restored the upper control arms, bead blasted, painted and new ball joint and bushings. He still has the lowers and the /6.

We are going to have to work around afternoon thunder showers all weekend....

Trying to get Cheryl let me reassemble it in the great room. We can put the top down get some popcorn turn on the big screen and pretend we are at the drive inn like we use to do..... She looked at me and said "um-no"..... Guess the honeymoon is over after 31 years.....

The RH patch panel arrived but the LH got delayed in Phoenix for some reason but that is plenty for this weekend.

Harbor Freight $4 mini vice grips work just fine for this.

Oh man that Duster extension hack is PERFECT...

Lets cut out the LH side so we can blast the inner fender tomorrow and epoxy prime it. Mask off at the body lines so the panel keeps it shape with the line in tact.

Ok this side is bad, I have no regrets on cutting it out and spending the $100 on the patch.

Mopar part number still intact but the mud trapped in the lip was getting aggressive.

The lip on the quarter was really bad on the LH side as I expected.

Here is the RH side with the 2 patch panels cut to fit. All I need to do is blast the inner fender behind these in the morning and epoxy prime the inner panel and the back of the new patches and the are ready to install.

I also blasted the K-Frame and the rear axel this morning but I was racing to make an appointment so I did not take any photos.

The RH patch panel arrived but the LH got delayed in Phoenix for some reason but that is plenty for this weekend.

Harbor Freight $4 mini vice grips work just fine for this.

Oh man that Duster extension hack is PERFECT...

Lets cut out the LH side so we can blast the inner fender tomorrow and epoxy prime it. Mask off at the body lines so the panel keeps it shape with the line in tact.

Ok this side is bad, I have no regrets on cutting it out and spending the $100 on the patch.

Mopar part number still intact but the mud trapped in the lip was getting aggressive.

The lip on the quarter was really bad on the LH side as I expected.

Here is the RH side with the 2 patch panels cut to fit. All I need to do is blast the inner fender behind these in the morning and epoxy prime the inner panel and the back of the new patches and the are ready to install.

I also blasted the K-Frame and the rear axel this morning but I was racing to make an appointment so I did not take any photos.

Well today was not as productive as it could have been.... the day started out like this....

So I worked on the little 7 1/4" in the garage while watching it rain. She has a 3.23 in her! That is what I wanted for the /6 I am happy!

Blasted it yesterday before pulling it apart

It has had a rear brake job in the recent past..

The old hose clamp trick around the E-Brake tangs then just tap with a screw driver and it pulls right out of the backing plate.

So I worked on the little 7 1/4" in the garage while watching it rain. She has a 3.23 in her! That is what I wanted for the /6 I am happy!

Blasted it yesterday before pulling it apart

It has had a rear brake job in the recent past..

The old hose clamp trick around the E-Brake tangs then just tap with a screw driver and it pulls right out of the backing plate.

Last edited:

If you don't like the weather in Arizona wait a few hours. Very very few days are rainy all day here. It cleared around 1pm so I was done blasting the axle parts and I had not cleaned my gun from yesterday with the black epoxy so I mixed up some more and dragged everything outside. I think I have about 95% of the parts that are black painted now.

Blasted the brake lines and cleaned and painted them with Seymours Stainless Steel paint.

Same with the E-Brake cables, cleaned and working freely then painted with Stainless Steel.

I really wanted to get the grey epoxy shot today but maybe I can get that done right after work one of these days this week so it is dry for the weekend to shoot with Stainless Steel. Anything that needs durability I shoot with epoxy primer with the Seymours over it. A small scratch in the SS paint only the grey primer shows through and it is almost invisible.

Blasted the brake lines and cleaned and painted them with Seymours Stainless Steel paint.

Same with the E-Brake cables, cleaned and working freely then painted with Stainless Steel.

I really wanted to get the grey epoxy shot today but maybe I can get that done right after work one of these days this week so it is dry for the weekend to shoot with Stainless Steel. Anything that needs durability I shoot with epoxy primer with the Seymours over it. A small scratch in the SS paint only the grey primer shows through and it is almost invisible.

Last edited:

Oh yea the wife chose classic slotted mags for the Dart!

U.S. Mags Indy U101 Polished Wheels U10115705437

U.S. Mags Indy U101 Polished Wheels U10115705437

Not glamorous work but necessary work and may as well kill a few hours after work to save those hours for the weekend. Grey epoxy (then Seymours Stainless steel) for the parts that are to be faux "natural" metal are cleaned with wax and grease remover and ready for spraying. There are a few more parts in the baggies from disassembly and a few parts are still on the car that need to be removed and blasted but this is 90% of them.

Dave at the machine shop knows how I like it. When he replaces bushings and ball joints he gives me the works.... bead blasted and painted with Seymours Cast Blast..... The lower control arms will look the same when he gets those bushings replaced.

Dave at the machine shop knows how I like it. When he replaces bushings and ball joints he gives me the works.... bead blasted and painted with Seymours Cast Blast..... The lower control arms will look the same when he gets those bushings replaced.

You got it down pat. But #3 in as many years I can see why. Looking good.

You got it down pat. But #3 in as many years I can see why. Looking good.

Like an assembly line man!

Last edited:

Like and assembly line man!

if it just wasn't for that damn sheet metal work I would be loving it. I really don't like sheet metal work and welding...

After years of travel to Brenham for work I can't cut a break and get another trip out there. I recently learned of that guy that has all those Mopars in a private collection just east of there and you can call him to get an appointment to see his private car collection....

JayinMI

Well-Known Member

Gonna be one fine '63 Dart in a few weeks...

Fixed. lol

Stripped the rest of the parts off the firewall and blasted everything that needs grey epoxy primer. I missed a few parts that should be black.... guess I mix a little black this weekend too. I have gotten my $99 back on the HB blasting cabinet. I could not image being without it.

Beautiful late summer evening in Southern Arizona.

Beautiful late summer evening in Southern Arizona.

Nothing like the smell of epoxy primer while watching the sunset....

Got up early to rattle can the Seymours Stainless Steel on this morning before work and after work shot it with SPI Universal Clear..... Tomorrow blasting, epoxy then welding of the new rear quarter patches!

-