You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

1966 Factory V8 Valiant Signet Restoration For My Other Daughter

- Thread starter Jim Kueneman

- Start date

-

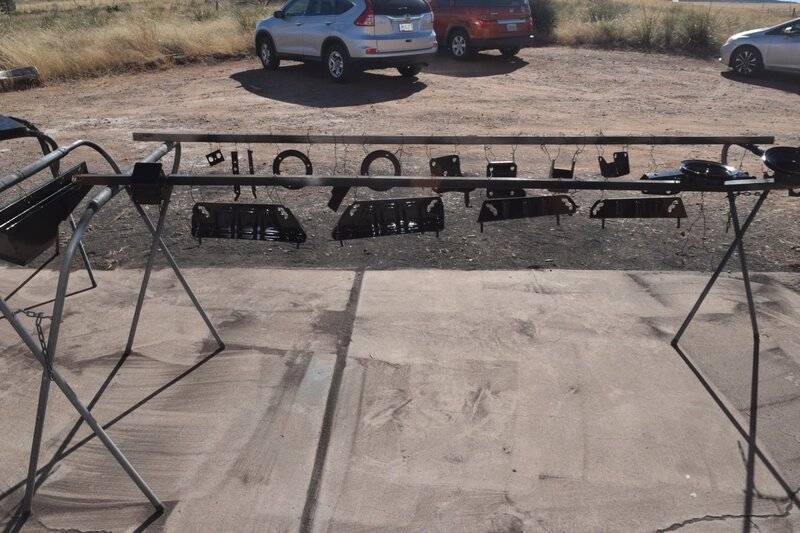

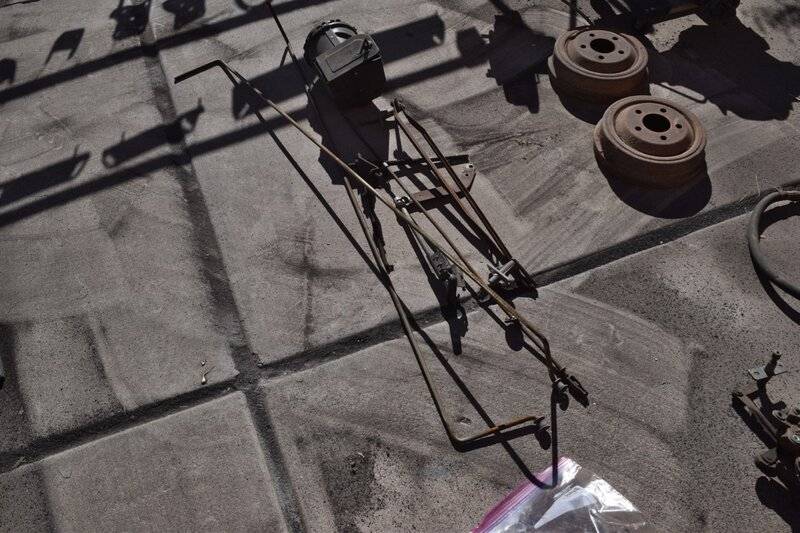

The seat tracks are going to take some work to get them freed up... All those parts I blasted when it was too cold to paint are now painted. We are having 3 days of perfect weather... they got brought into the house once it cooled down to keep them warm overnight.

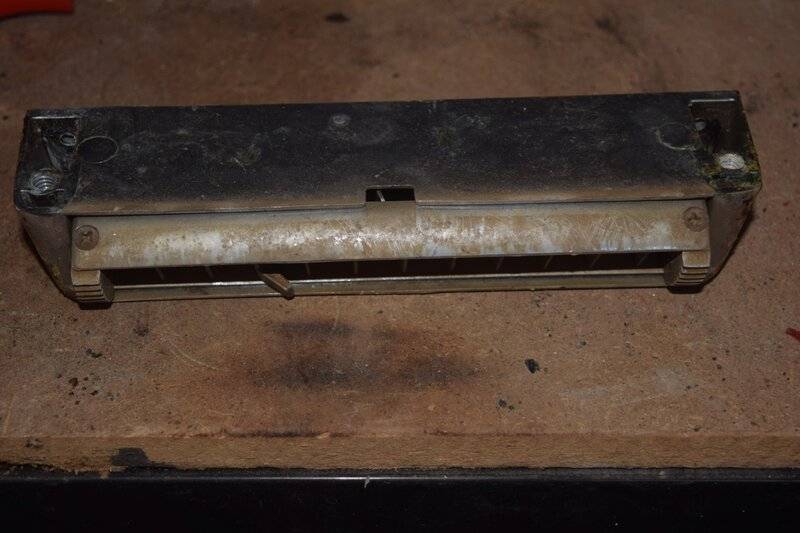

Well I don't really want to blast another dash but this one does not have the extra switch hole drilled into it. What's worse welding the hole up or blasting a good dash.. I will just blast the good dash. Took the under dash vents apart to blast and paint... boy this thing has some heft compared to 6 years later where this is just a hyper thin piece of plastic... I don't understand I just painted all the blasted parts where did these come from! More painting and blasting tomorrow...

Last edited:

Soak them in a bucket of Apple cider vinegar, it will knock the rust out of it.The seat tracks are going to take some work to get them freed up... All those parts I blasted when it was too cold to paint are now painted. We are having 3 days of perfect weather... they got brought into the house once it cooled down to keep them warm overnight.

View attachment 1715848069 View attachment 1715848070 View attachment 1715848071 View attachment 1715848072 View attachment 1715848073 View attachment 1715848074 View attachment 1715848075 View attachment 1715848076 View attachment 1715848077

As promised, blasted the dash... unfortunately it has rust pits in the top surface i will have to fill and sand... This takes care of 90% of everything that needs black epoxy...

An the pile for tomorrow, it is growing a lot smaller! This pile needs grey epoxy like the backside of the dash.. I always paint the backside of dashes a light color so that light bounces around so working under the dash is not a black hole..

mopowers

Well-Known Member

Awesome progress! What kind of paint are you using for all those black items?

Awesome progress! What kind of paint are you using for all those black items?

Southern Polyurathanes Epoxy primer it comes in black gray white and oxide red. It should last forever. It has a semi gloss shine and UV protection

And it sands super easy after a couple days unlike most other Epoxy primer’sSouthern Polyurathanes Epoxy primer it comes in black gray white and oxide red. It should last forever. It has a semi gloss shine and UV protection

Took the wife to brunch in the convertible so today was a slacker day... Took most of the chrome and trim to Tucson to Capital Metal Finishing to get redone. Once home I was excited about chrome and pulled the AC vents apart ready to take down for new chrome. These are a work of art and hefty!

The steering wheel needed to be pulled apart to do a nice job. I carefully drilled out the pot metal "crush rivets" and pulled it down to its bones. I will drill and tap the pins for #6 screws to reassemble. Looks like another trip to Capital... especially since I forgot to take the quarter panel spears.

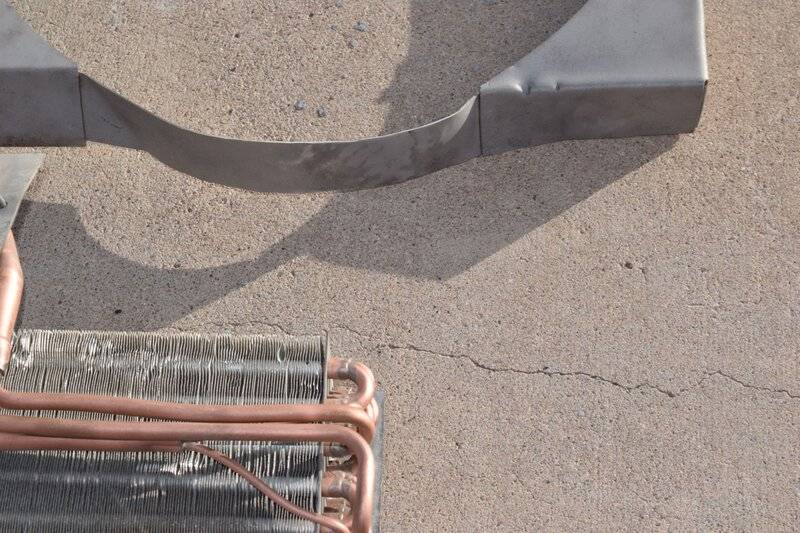

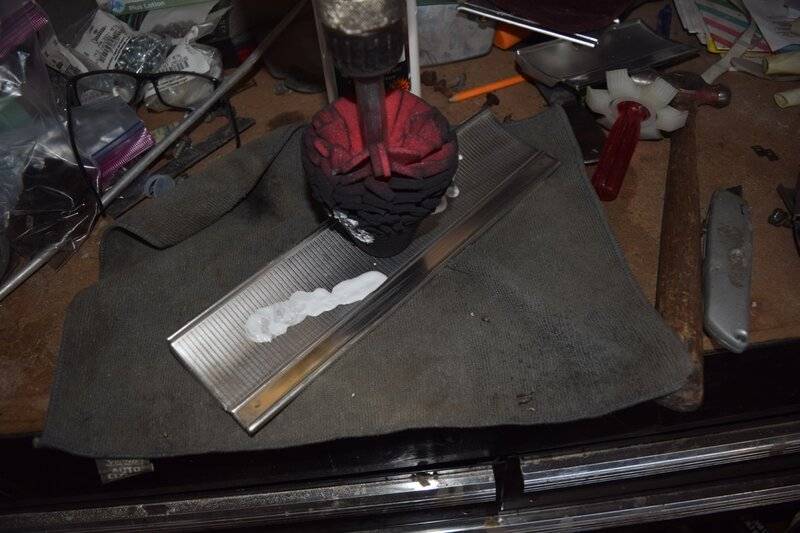

A windy cool day, not so good for painting but good for blasting... Today was the annoying parts that needed work. The AC evaporator pipes were way out of whack so I worked them back flush. Combed the fins to get rid of the flatten out spots that would block airflow. Need to pressure test it in a tub of water next. The fan shroud had been introduced to the fan so it needed some metalwork and welding. It is incredible that I got the heater shut off valve working with the bead blaster... it looks like new now and the actuator is functional... now will the shaft seal leak coolant?

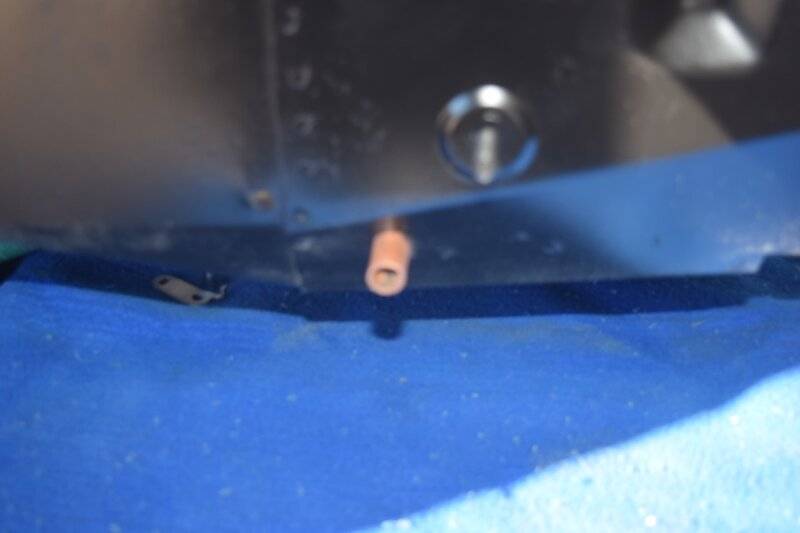

You can see the pile of parts in the driveway is effectively gone. Just the axle, AC compressor with the /6 brackets that I am not using, the seatbelts that I need to wait for the wife to leave the house so I can put them in the dishwasher for a few cycles and a box of mounting hardware! It sucks that the AC lines that would have been common for the V8 and /6 someone could not go buy the right expansion valve and cut the lines and welded in 45 degree compression nuts because they used an expansion valve with compression fittings instead of o-rings... really...

You can see the pile of parts in the driveway is effectively gone. Just the axle, AC compressor with the /6 brackets that I am not using, the seatbelts that I need to wait for the wife to leave the house so I can put them in the dishwasher for a few cycles and a box of mounting hardware! It sucks that the AC lines that would have been common for the V8 and /6 someone could not go buy the right expansion valve and cut the lines and welded in 45 degree compression nuts because they used an expansion valve with compression fittings instead of o-rings... really...

Wanted to just shoot the back of the dash grey (so it will reflect light in the future when working under the dash vs black hole)... well I miss calculated and ended up with enough to paint a few more parts.... Then I got brave and shot the Automotive Arts Motocryl matte black.... Jimmy like Motocryl! This stuff lays out nice and looks very much like the original finish! In the photo below it had not finished flashing.. it is a nice consistent matte black now. I have some gloss too that I will shoot the door and quarter interior with as well.. Earlier in the day I worked on restoring the AC head and dash plate. This is a newer B-Body style switch but it will work with one jumper and a swap of 2 of the vacuum hoses... either that and $90 NOS or buy the correct AC switch NOS at $400+, easy choice. Of course one has to mock this up when they are playing shooting the final coat!

It is embarrassing to Chrysler how easily that black paint came off with Acetone... Two wipes and it was gone! White Diamond is teh polish recommended by several professionals. It works great. 3M vinyl masking is required for sharp lines... Then it was time to start assembling new parts!

Called Year One today... M&H is having a bad time with labor and raw materials and harness are only trickling in.... I will suck if I am hung up on assembly because of harnesses....

Mineallmine

Well-Known Member

As usual, amazing work. At this pace, you'll get your second car done before I finish my first.

This is exactly why your build that I'm removing my windshield not half *** it pulling my dash out and pulling the damn harness and redoing it because I did have the amp meter burned up wire and the dead dash from all the water in it and it's just smart I don't want to do it but I'm doing it.Called Year One today... M&H is having a bad time with labor and raw materials and harness are only trickling in.... I will suck if I am hung up on assembly because of harnesses....

View attachment 1715851102 View attachment 1715851103 View attachment 1715851104 View attachment 1715851105

Man this hurt but NOS mean no problems in the near future.

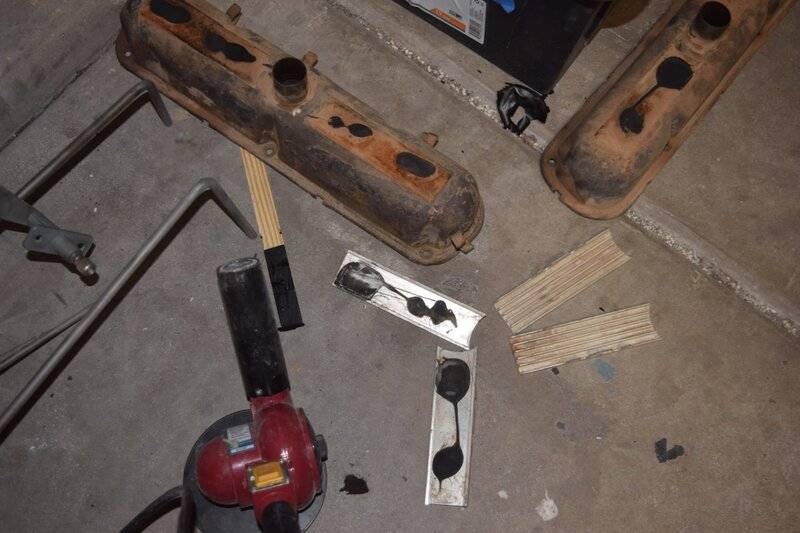

Commando valve covers.. to get the wire holder off just heat with a heat gun... they will pop right off. They are in getting polished. Pulled the blower motor apart and polished up the shaft so it will spin easily. I ended up driving the shaft with respect to the armature while I was trying to get it apart the first time but a few careful taps got it all lined up again... It should turn freely and not get hot running for extended time.. I had to pull it apart a couple of times to get the end play and burrs a few burrs off the shaft so it would not get hot.... Put the evaporator in a tub of water and used an air hose at 100 psi to look for bubbles. Looked fine.

Just a lot of detail cleaning and painting while assembling the AC box and fresh air vent... Detroit Muscle Technology kits are the best.. I got a template from someone to cut the holes in my firewall but what the heck may as well use it to keep the box stable since it is sort of an AC box and a separate Heater box held with one lousy bolts... Heater core is the same as the non AC and this one Bob at GlenRay did for me a few months ago..

Refurbished all the switches and installed... had polished the knobs last night. Went to Tucson to pick up $14 dollars with of capacitors and the Radio works just fine.

Next up is the dash pad....

Well did not get to the dash pad.. had to get the car out to put the Christmas decorations up so I just spent the day breaking my back with guide coat and 320 grit blocking.... There is a mystery with these cars and the quarter top spears... It appears that there were TWO different lengths and the replacement quarter I got had the longer one... Thank goodness I test fit the spears I got a few weeks ago before taking them to the polishers! If I had this painted then realized that the groove was 2" to long on this side I would have been pi$$ed..... Also the sun is a powerful tool for body work... the shadow cast was not consistent on the RR quarter so I got out the hammer and dolly and made some adjustments. Then blocking along the panel to get the shadow as straight as possible. The trunk almost done.. found one low spot... The hood I knew needed work and it is now ready for the final coats of epoxy to block out to perfection. Stick a fork in the roof it is blocked with 320 to perfection... A couple more coats of epoxy and blocking out with 400 and it is ready for paint. I was going to shoot epoxy on the hood, trunk and fixed spots but it was getting late and I did not clean my epoxy gun very well last time I used it.. This is NOT the time for a crappy finish and orange peel as I am trying to get it _smooth_.... I decided not to push it. The days are getting longer and the temps are starting to rebound, I will wait.

-