Obviously this is an example of “I don’t know if I can do this” versus “this is what I want to do and I’m going to do it.” I need to remember that on a regular basis. A lot of good work, good example, and good info here.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

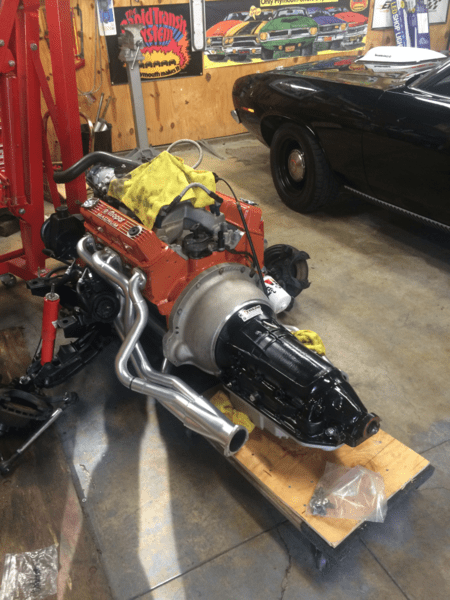

1966 with gear vendor

- Thread starter Mopar Tim

- Start date

-

Mopar73340

Well-Known Member

I hope the MSD is better and bullet proof. It's nice to set it and forget it. I ran a bypass wire to the dimmer switch control in the floor, so I could get home with the RV. The GV that I had in the Challenger.....it was fun splitting gears for a few days, and it quickly became more trouble than it was worth! I did like the way it toned the 3.55 gears down on the interstate though!

I normally just leave it in auto mode and let it do it’s thing although I used manual mode exclusively the past two years due to the old controller not working correctly. Splitting gears gets old quickly.

I learned of the new controller made by MSD while at SEMA. Supposedly GV was unable to create one that could filter the electrical noise that’s common in our older vehicles out of the circuits and this is what caused the erratic behavior. So far the MSD one is working ok. I’ll keep my fingers crossed!

Going to cut a piece of wood to the correct profile, then use a jack to press up, and hammer it till it gives!!

View attachment 1715689247

I am considering using my shop press. To form steel....

What are your plans to restore the integrity of the transmission cross member (the part that is a portion of the torsion bar frame that you cut a piece out of)?

Good question. Planning on reusing cut out piece. Cut smaller and weld in place. It will just fit I think...What are your plans to restore the integrity of the transmission cross member (the part that is a portion of the torsion bar frame that you cut a piece out of)?

Good question. Planning on reusing cut out piece. Cut smaller and weld in place.

If you can, you might consider welding the result to the floor pan, as opposed to the few factory spotwelds involved, to stiffen the piece because you lost a lot of strength there and that part of the frame (the whole piece) is pretty critical. If you do that and have room above, you could make a piece to go above it over the floor pan and weld it in place too.

No way above. Center console. When the cross member is bolted in. It makes the area strong.If you can, you might consider welding the result to the floor pan, as opposed to the few factory spotwelds involved, to stiffen the piece because you lost a lot of strength there and that part of the frame (the whole piece) is pretty critical. If you do that and have room above, you could make a piece to go above it over the floor pan and weld it in place too.

Not really lost a lot of strength. The cross member is the strength.If you can, you might consider welding the result to the floor pan, as opposed to the few factory spotwelds involved, to stiffen the piece because you lost a lot of strength there and that part of the frame (the whole piece) is pretty critical. If you do that and have room above, you could make a piece to go above it over the floor pan and weld it in place too.

Kendog 170

Let the boy go !

Would you with a RB 500 stroker ?Knowing what I know now....I'll use an A500 or A518 if I ever want OD in another Mopar.

.I'll use an A500 or A518 if I ever want OD in another Mopar.

Would be a lot more issues and fabrication.....In Early....A

Ok. Resized cut out piece. Gave it a test fit before welding in place

View attachment 1715690541

View attachment 1715690542

View attachment 1715690543

View attachment 1715690544

JDMopar

Well-Known Member

Would be a lot more issues and fabrication.....In Early....A

Definitely! That's why I'm just building a 998 to put in my 65 Barracuda, and see if the fresh 273 can get out of it's own way and still get 25+ MPG with 3.23's.

jbc426

Well-Known Member

I'm surprised that it required so much cutting. Almost everyone else has said it just takes a big hammer on the floor to make them fit.

I didn't even have to cut my floor to install a 2004R, but it is much smaller that the GV unit especially in length. I did cut the cross-member and welded a 1/4 inch plate about 3 inches wide and 2 feet long that I heated and shaped on top of the floor above the cross-member. It was hard to bend when red hot, so its pretty ridged cold and you can't see it under the carpet. I welded the entire cross-member solid to the floor pan.

I didn't even have to cut my floor to install a 2004R, but it is much smaller that the GV unit especially in length. I did cut the cross-member and welded a 1/4 inch plate about 3 inches wide and 2 feet long that I heated and shaped on top of the floor above the cross-member. It was hard to bend when red hot, so its pretty ridged cold and you can't see it under the carpet. I welded the entire cross-member solid to the floor pan.

Not in EARLY A body car. Much different.I'm surprised that it required so much cutting. Almost everyone else has said it just takes a big hammer on the floor to make them fit.

I didn't even have to cut my floor to install a 2004R, but it is much smaller that the GV unit especially in length. I did cut the cross-member and welded a 1/4 inch plate about 3 inches wide and 2 feet long that I heated and shaped on top of the floor above the cross-member. It was hard to bend when red hot, so its pretty ridged cold and you can't see it under the carpet. I welded the entire cross-member solid to the floor pan.

View attachment 1715691023

jbc426

Well-Known Member

Not in EARLY A body car. Much different.

No doubt. My point was the use of 1/4 inch plate that follows the shape of the original floor to bridge the cut out section is relatively easy to make and very effective. The torsion bar cross member does have a significant amount of stress going into it from engine torque and deflection from the torsion bars. More rigid is definitely better there.

This is how much it needed. It is pushed up as far as it would goNo doubt. My point was the use of 1/4 onch plate that follows the shape of the original floor to bridge the cut out section is relatively easy to make and very effective. The torsion bar cross member does have a significant amount of stress going into it from engine torque and deflection from the torsion bars. More rigid is definitely better there.

jbc426

Well-Known Member

This is how much it needed. It is pushed up as far as it would go

View attachment 1715691033

I see. Did the case of the unit protrude that much above the original floor shape once you made room?

Welded in the original piece, just flattened some...No doubt. My point was the use of 1/4 inch plate that follows the shape of the original floor to bridge the cut out section is relatively easy to make and very effective. The torsion bar cross member does have a significant amount of stress going into it from engine torque and deflection from the torsion bars. More rigid is definitely better there.

Yes had to cut out the floor as well....I see. Did the case of the unit protrude that much above the original floor shape once you made room?

Just mocked up but you can see the needed distanceI see. Did the case of the unit protrude that much above the original floor shape once you made room?

the front is to the right...

-