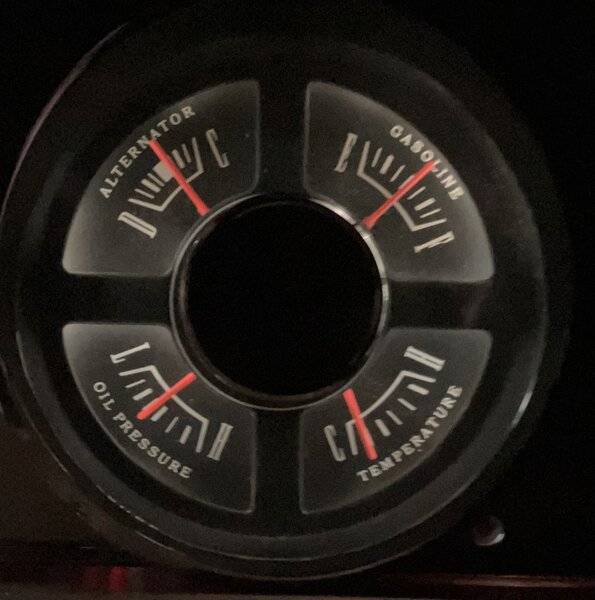

Bench tested cluster lights and gauges

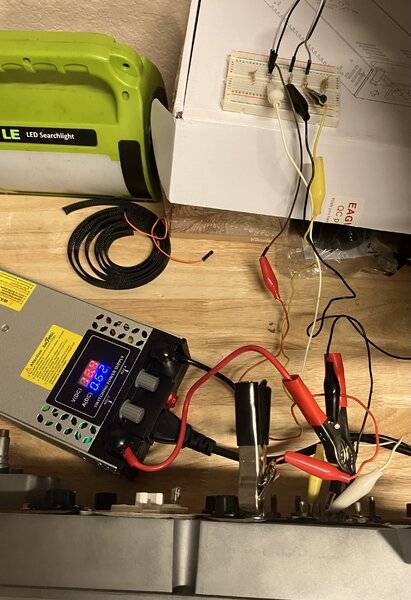

voltage input @ 13.4 Volts to test the voltmeter, various resistors to simulate sending units for oil, fuel, and water.

The stock style bulbs did not put out much light. Since the lenses are blue I opted for blue LED bulbs. Tested between 5 and 13.5 Volts, dimming worked fine. Ran into a funny issue. The “new” holders for the bulbs have a spring clip, when you insert the LEDs all the way in they contact point is above the exposed wires on the bulbs. Because of this they didn’t work. But, pull them out slightly and they are fine. May have to make little plastic spacers.

voltage input @ 13.4 Volts to test the voltmeter, various resistors to simulate sending units for oil, fuel, and water.

The stock style bulbs did not put out much light. Since the lenses are blue I opted for blue LED bulbs. Tested between 5 and 13.5 Volts, dimming worked fine. Ran into a funny issue. The “new” holders for the bulbs have a spring clip, when you insert the LEDs all the way in they contact point is above the exposed wires on the bulbs. Because of this they didn’t work. But, pull them out slightly and they are fine. May have to make little plastic spacers.