Hemiorangeswinger

Dodge Material

I got the rest of the pan welded tonight (except the firewall area) that was a lot of plug welds! I orbitaled all my welds with 80grit, scotch brited around the areas and put some epoxy down. I will then put my fiberglass filler over the epoxy to fill in any grind marks to make a seamless repair and re epoxy the entire pan once the firewall area is welded up and the four speed hump is in. I still need to drill the holes in the pan for the bench seat and weld in the new floor wiring covers.

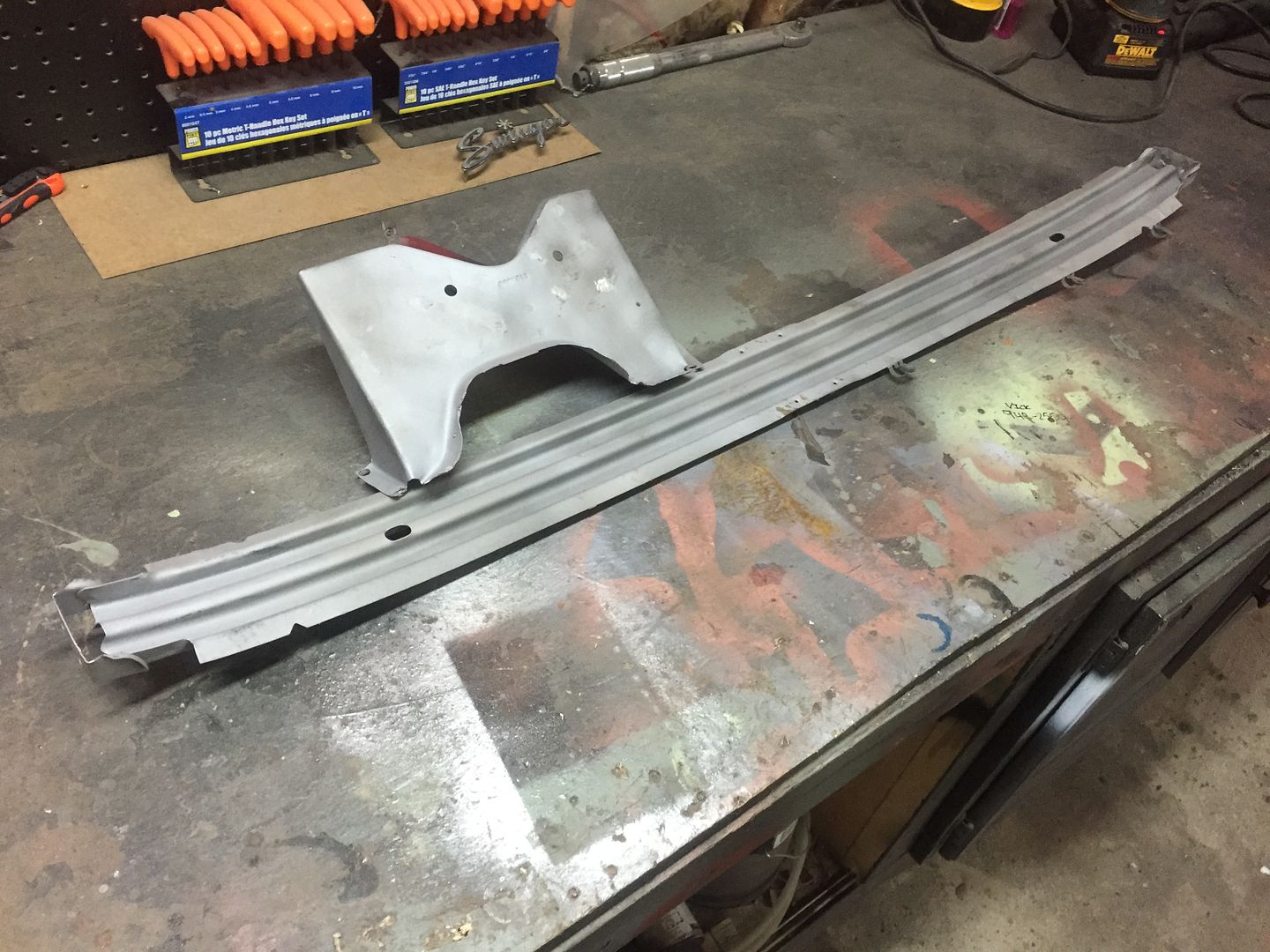

I also have to weld the seat stopper to the four speed hump and modify the hump where the shifter boot screws to since the AMD one is wrong..

My custom floor clamper!

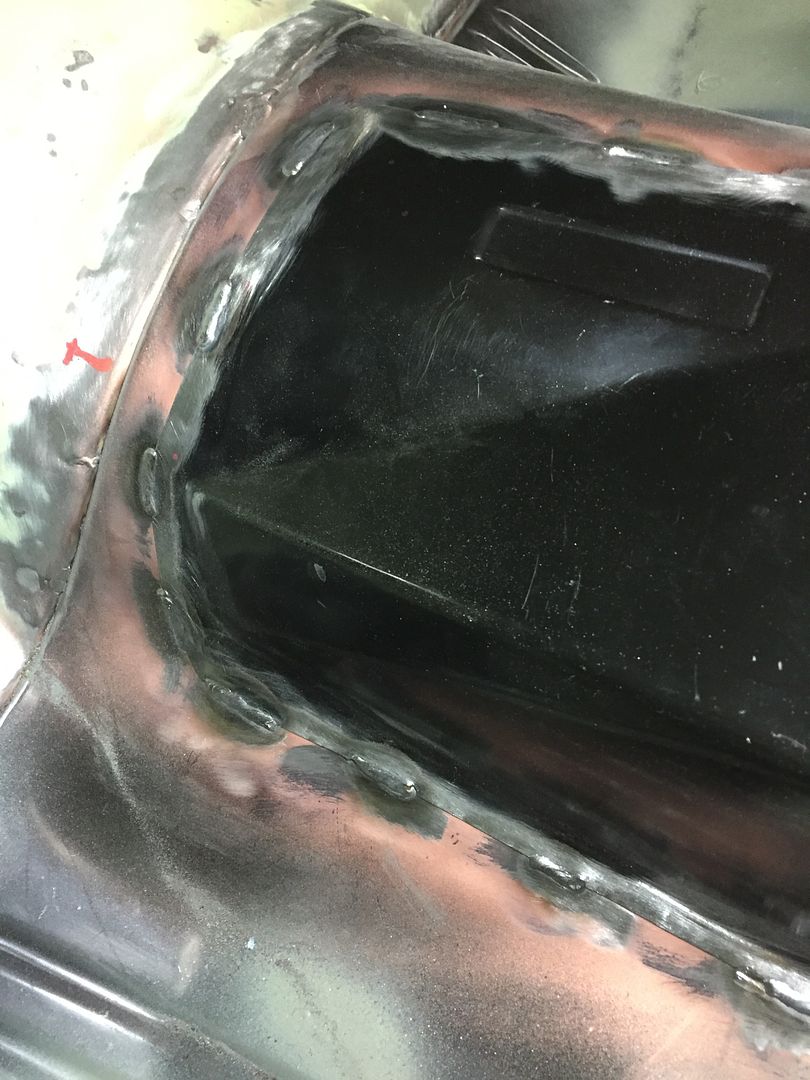

Epoxied the the bottom side of the cowl as well.

I also have to weld the seat stopper to the four speed hump and modify the hump where the shifter boot screws to since the AMD one is wrong..

My custom floor clamper!

Epoxied the the bottom side of the cowl as well.