the chamber is likely smaller than 4.100. besides that chamber needs workYou have to be careful opening the chamber up bigger than the bore.

You can create more issues doing that.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

340 stroker 422

- Thread starter Miszny

- Start date

-

Rat Bastid

Dunamis Metron

4.180 gasket, bore is 4.100…

Thats .040 per side. You should be fine opening the chamber than far.

Rat Bastid

Dunamis Metron

Tire will be 27 or 28” tall, copper cobra 275 or 295.

I was planning to use mild timing curve in msd distributor, also limit max timing and use cold plugs.

So at 70 MPH what does that give you for a cruise RPM?

This is 100+ actually. Works perfect in 12.5:1 big blocks with not big 270/[email protected] cam.100 RON is about 96 in the US....still good stuff

About 3300 without overdrive and 2500 with overdrive.So at 70 MPH what does that give you for a cruise RPM?

I have 3200 converter for this thing.

unshroud the valves.

Rat Bastid

Dunamis Metron

About 3300 without overdrive and 2500 with overdrive.

I have 3200 converter for this thing.

Unless the road is very flat, at 2500 in OD you’ll have a bugger of a time keeping it out of detonation. Any little change in load will get it into tip in detonation.

You’ll have to be very careful.

At this point in time I'd cleanup the chamber and use a 0.050 head gasket and send it.

Plan was to make it a good driver…Unless the road is very flat, at 2500 in OD you’ll have a bugger of a time keeping it out of detonation. Any little change in load will get it into tip in detonation.

You’ll have to be very careful.

Is that head gasket really going to do much? It’s like 11.8:1 with quench vs 11.5:1 without quench…At this point in time I'd cleanup the chamber and use a 0.050 head gasket and send it.

there's still quench at 0.050, it's the limit. Don't you think there's something to be gained by working the chamber?Is that head gasket really going to do much? It’s like 11.8:1 with quench vs 11.5:1 without quench…

Rat Bastid

Dunamis Metron

Plan was to make it a good driver…

Then you missed on the compression ratio. You have to make compromises somewhere.

I‘s work on getting the compression down to 11:1 if you want to run that gearing.

What does a 4.10 gear look like for cruise RPM?

Piston is not at zero deck.there's still quench at 0.050, it's the limit. Don't you think there's something to be gained by working the chamber?

Was going to be a bit deeper in but block was very bad and needed a lot of decking.

Rat Bastid

Dunamis Metron

Ok, so how are you figuring your compression ratio? If you don’t do a down fill you are relying on numbers then piston manufacture gave, and those aren’t always right.

You need to do a down fill and do the math and see exactly where you are.

You need to do a down fill and do the math and see exactly where you are.

There is no option to run 4.10 in this, it’s already crazy over invested project ;-)Then you missed on the compression ratio. You have to make compromises somewhere.

I‘s work on getting the compression down to 11:1 if you want to run that gearing.

What does a 4.10 gear look like for cruise RPM?

I’ll work on the chambers and cc them to see where it takes me I guess.

I should have one chamber ready tomorrow.

Fact is that I need 70cc chamber to be at 11:1 which is unrealistic I guess.

70 is possible with that head. 5cc’s out of that head is do-able.

The shape is the important part now.

I like the direction this is going in. Everything is pointing towards a good direction. Ratbastard is on target. Been there done this myself. No 2 cents to add in.

The shape is the important part now.

I like the direction this is going in. Everything is pointing towards a good direction. Ratbastard is on target. Been there done this myself. No 2 cents to add in.

Any pointers? Chamber photos?70 is possible with that head. 5cc’s out of that head is do-able.

The shape is the important part now.

I like the direction this is going in. Everything is pointing towards a good direction. Ratbastard is on target. Been there done this myself. No 2 cents to add in.

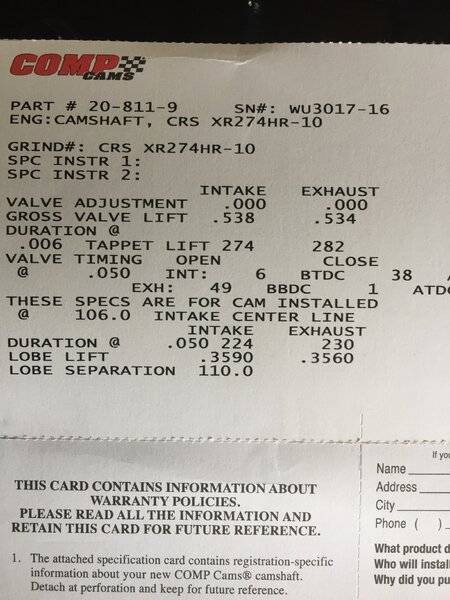

A FWIW cam card I’m running at the previously posted 11-1- 360 engine. I think your combo is going to work as discussed.

I run it with 1.6 rockers.

I run it with 1.6 rockers.

Sorry, no can do. All are on running engines and I don’t have photos.Any pointers? Chamber photos?

Change pistons or machine a dish in them.

You need to find about 12-14cc's, not easy to do.

You need to find about 12-14cc's, not easy to do.

Rotating assembly is already balanced as is. The only thing I can touch is the heads at this point and play with gasket thickness.Change pistons or machine a dish in them.

You need to find about 12-14cc's, not easy to do.

If you machined the pistons, the change in weight would likely do nothing to negatively effect the balance.

Read up on overbalance/underbalance and most engines run just fine in a range of 48-52% of bobweight. 50% being the typical bullseye. Say you had a 1900 bobweight, an acceptable range on that is 1862 to 1938

You are taking about 16 grams out of the bobweight with a 12 cc relief in the top on your piston.

Read up on overbalance/underbalance and most engines run just fine in a range of 48-52% of bobweight. 50% being the typical bullseye. Say you had a 1900 bobweight, an acceptable range on that is 1862 to 1938

You are taking about 16 grams out of the bobweight with a 12 cc relief in the top on your piston.

Miszny:

[1] Leave the heads alone. Run it like it is. If you look at other aftermarket parallel valve heads [ Chebby, BBM, Pontiac, Ferd Windsor, etc ], they all vary slightly in the combustion chamber design....but all run well.

[2] I have had 8.5:1 engines detonate on 98 fuel, but my 9.9:1 engine doesn't detonate on 91 fuel. You have to run it to see......

[3] I agree with installing the cam straight up on 108 ICL because of the cam duration & 3.9 gearing.

[4] Did the E heads come with beehive springs?

[1] Leave the heads alone. Run it like it is. If you look at other aftermarket parallel valve heads [ Chebby, BBM, Pontiac, Ferd Windsor, etc ], they all vary slightly in the combustion chamber design....but all run well.

[2] I have had 8.5:1 engines detonate on 98 fuel, but my 9.9:1 engine doesn't detonate on 91 fuel. You have to run it to see......

[3] I agree with installing the cam straight up on 108 ICL because of the cam duration & 3.9 gearing.

[4] Did the E heads come with beehive springs?

Heads were bought bare, they have new valves, guides, springs seals and locks. Springs to match the small hydraulic roller cam which will be used with solid roller lifters.Miszny:

[1] Leave the heads alone. Run it like it is. If you look at other aftermarket parallel valve heads [ Chebby, BBM, Pontiac, Ferd Windsor, etc ], they all vary slightly in the combustion chamber design....but all run well.

[2] I have had 8.5:1 engines detonate on 98 fuel, but my 9.9:1 engine doesn't detonate on 91 fuel. You have to run it to see......

[3] I agree with installing the cam straight up on 108 ICL because of the cam duration & 3.9 gearing.

[4] Did the E heads come with beehive springs?

So do I need to retard the cam 6 degrees now? Straight up it was 102.5 icl, I retarded it 2 degrees to be at 104.5

I just realized these are 65cc heads not 63cc by looking at part number of the castings.

-