dgc333

Well-Known Member

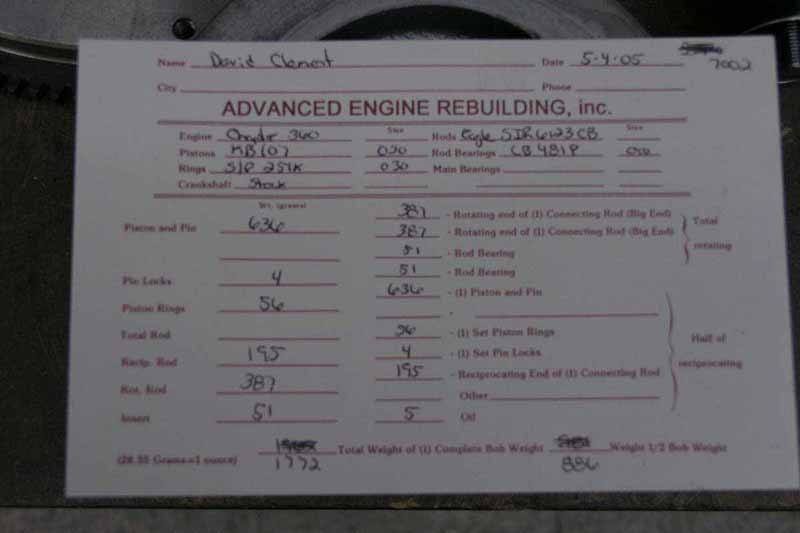

Just picked up my block and crank from the machine shop and though you folks would like to see some pictures of the work;

dgc333 said:Don't have the numbers to the pennies but it borke down like this;

Clean the block, magnaflux, measure to determine work needed: $225

turn and polish the crank : $125

measure and balance rotating assembly: $375

Deck and bore block: $575

There not the cheapest around but have a great reputation in the hot rod circles. They do a lot of high performance work on all brands and have a big following in the Harley circles. Super clean shop and they take a lot of pride in their work (they gave me the CD with all the pictures of the work on my engine).

FASTBACK340 said:I'm having the same thing done except for the balancing since I'm not changing to lighter rods. Plus I had the mains honed for the ARP studs. But where I'm having it done looks like a chop-shop! Damn place is cluttered and packed with stuff. But he too has a great reputation.... Supposedly the #88 truck in the Hooters race this weekend has one of his engines in it. He left for Florida this morning.....

color][/font]

dgc333 said:This!

dgc333 said:Oh! :\

Hedman 1 5/8" headers into a 2.5" exhaust with 50 series Flowmaster Delta Flows.

QUOTE]

do you know how the 50 series flowmaster compare with the dynomax super turbo's for sound? i am trying to decide on which way to go. I just bought a set of tti ceramic coated headers.

freshayr said:do you know how the 50 series flowmaster compare with the dynomax super turbo's for sound?

freshayr said:dgc333 said:Oh! :\

Hedman 1 5/8" headers into a 2.5" exhaust with 50 series Flowmaster Delta Flows.

QUOTE]

do you know how the 50 series flowmaster compare with the dynomax super turbo's for sound? i am trying to decide on which way to go. I just bought a set of tti ceramic coated headers.

Well I would say the 50 series are quieter than the short super turbo's and about the same as the longer hemi super turbo. I have a buddy with a built 360 tti's and a 2.5" system with 50 series Flowmasters in his Barracuda. It sounds great, just enough rumble to know there is something under the hood but not so much to drive you nuts with interior resonance.

FWIW, I have a 3" single 50 series SUV muffler (thicker than the standard 50 series) on my Dakota and you get the flowmaster sound at idle and WOT but going down the road it's barely noticable. This is just what I want for the Cuda, the glass-paks under the car now wear on you after an hour or so on the hiway.

I like Dynomax Super Turbos and have used them on a number of vehicles over the years. I am going with the Flowmasters because my daughter is doing the exhaust over for me at her muffler shop and they stock Flowmaster and Magna Flow products. I had thought about the Magna Flows but since Katie is doing this as a freebee for me and the Flowmasters are less expensive I figured that I would not hit her bottom line any more than necessary.