just trying to help here. egag has a dual pattern airgap styly knock off from kmj performance item number 392947209070 for 199.00 w/free shipping. just trying thelp if m1 is too much.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

360 Magnum Build w/ V Belt Configuration Question

- Thread starter Six Barrel Bill

- Start date

-

rdunnam

RDunnam

Is that Promaxx iron head a China cast you think? I know Hughes offers an iron head also, haven't looked up lately.For cylinder heads, there are available for you in;

Iron, stock replacement style.

Once such example below, do shop around though.

CHRYSLER 5.2/5.9 MAGNUM New Full - PROMAXX Performance Products

Edelbrock aluminum for the first step up in performance.

Edelbrock Performer RPM Chrysler Magnum Cylinder Heads 61775

Trick Flow heads that will then use a LA intake but yet you will still be able to oil through the pushrods with the correct Harland Sharp rocker arms.

Parts and Accessories - cylinder-heads part-type - trick-flow-powerport-190-cylinder-heads-for-small-block-mopar product-line

You can also use Comp Cams Pro Magnum rocker arms to use oil through pushrods on stock or Edelbrock heads since they allow pushrod oiling. The last two options allow the use of cheaper & a wider verity of LA intake manifolds.

Six Barrel Bill

Well-Known Member

After a lot of thought, investigation and working with our engine builder. I believe these are the heads we are going to go with. Of course you can go with more expensive heads that are made out of aluminum but for my daughter's budget and based on these performance numbers it seems like a good deal.

https://www.performanceinjectionequipment.com/mopar-eq-cylinder-heads

https://www.performanceinjectionequipment.com/mopar-eq-cylinder-heads

The iron head? I’m sorry, I really don’t know. Call ProMaxx up. They were really good to talk to on the phone. FWIW, I’d buy from them again.Is that Promaxx iron head a China cast you think? I know Hughes offers an iron head also, haven't looked up lately.

The aluminum head? Yes. They get it bare and work it from there. There CNC port job on there Maxx series doesn’t address the short side, the port floor is largely/mostly/completely (?) left alone, so there is a lot left in the head flow wise. A quick glance (@ best) is all it got from me. It looked as cast. I really didn’t G.A.F.

The work is what I’d call a safe porting. It’s not a full blown porting. You can absolutely build a quick car with those heads.

Bobzilla

Well-Known Member

Have you talked to PIE about these heads? That is the same description they used when they were preparing the good Engine Quest heads that were cast in New Zealand. Do not trust any advertisements right now about cast iron Magnum heads. Most places still have the same info, but they are using the stock style replacement castings, since nothing else is currently available.After a lot of thought, investigation and working with our engine builder. I believe these are the heads we are going to go with. Of course you can go with more expensive heads that are made out of aluminum but for my daughter's budget and based on these performance numbers it seems like a good deal.

Mopar EQ Cylinder Heads

Is there a problem with the old heads on your engine? If not, just run what you have and save your budget a bunch of money.

Six Barrel Bill

Well-Known Member

Well visually the heads seem to be okay but I haven't had them apart. But as things do, this engine build has turned into a different direction. The stock heads are not going to work for where we're headed. In talking with my machinist who I've worked with before (quite a few years ago he built a 360 LA motor for my wife's 'Cuda, that thing was freaking hot!).Have you talked to PIE about these heads? That is the same description they used when they were preparing the good Engine Quest heads that were cast in New Zealand. Do not trust any advertisements right now about cast iron Magnum heads. Most places still have the same info, but they are using the stock style replacement castings, since nothing else is currently available.

Is there a problem with the old heads on your engine? If not, just run what you have and save your budget a bunch of money.

There's a .001 difference between the piston and bore so at this point we're looking at 11:1 pistons, I beam rods and coming up with a cam combination. I've had to reel him in several times and remind him this is a street engine for my daughter

I did actually call PIE and talk to them about this head. But it was more about the flow and work that has been done to them, but not actually where they started from. Another machinist vouched for these heads from this company as he has built a few magnum motors and used them. So, we started looking into it but haven't made a definitive decision. Like I said, right now we're putting together the bottom end combination so we can work our way up.

I have a M1 dual plane intake I would trade you for your single plane if it is in good shape. As in no stripped bolt holes or cracked or warped or ground on. PM me if interested.

67dartgtgo

Well-Known Member

I'm running the magnum eddy air gap with LA cover, water pump and pully's with power steering. I used the stock LA hose in question and it was a ***** to get on with the long air gap fitting that came with the intake but you can muscle it on with no kinks and get a smooth profile if your patient with it. This is the second hose I installed as I did a cam swap and replaced the first hose which I had trimmed to fit. I wasn't as happy with the first/trimmed hose as I am with this one. I was definitely more patient the second time.

rdunnam

RDunnam

67Dart GTO...I mean GTGO, I have the same intake and planning the same set up. Just pulled fitting out the box, you think it might help a little to trim the fitting down shorter, cut the first 2 barb notches off of the total five, leaving 3 ? I don't think it would hurt. Yours appears fine. Motor detail is excellent, looks very good. What heads and cam specs you running?I'm running the magnum eddy air gap with LA cover, water pump and pully's with power steering. I used the stock LA hose in question and it was a ***** to get on with the long air gap fitting that came with the intake but you can muscle it on with no kinks and get a smooth profile if your patient with it. This is the second hose I installed as I did a cam swap and replaced the first hose which I had trimmed to fit. I wasn't as happy with the first/trimmed hose as I am with this one. I was definitely more patient the second time.

View attachment 1715628063

67dartgtgo

Well-Known Member

I don’t think it would hurt as long as you have enough clamp room.

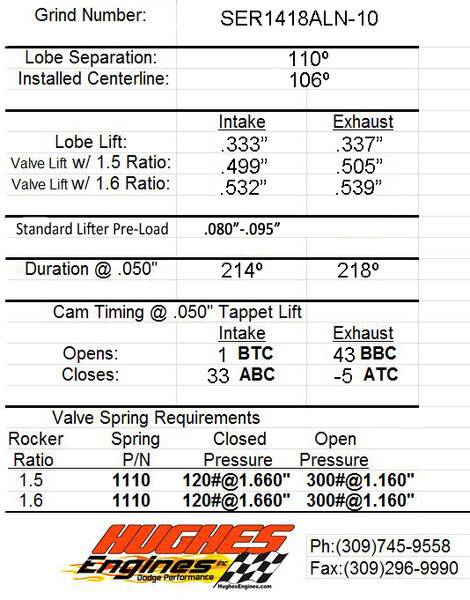

Thank you for the compliment. My magnum is a mopar performance 5.9 320hp ....1998. Bought just before the 380hp came out. Had the M1 dual plane on it when it was new. Still running the stock heads with upgraded valve springs from Hughes...just did a cam upgrade last winter with this one. I’d like to do an eddy head upgrade at some point. Be aware the lift on this cam is fairly high for stock magnum heads. Measured carefully for clearance and Hughes said it wouldn’t be a problem. So far so good to 5800rpm. This is the highest lift cam they recommended to me for stock heads. Runs very well for me with a 46rh and 3.55’s with good street manners. Research for what you want and other components your running is key to cam selection for sure.

Thank you for the compliment. My magnum is a mopar performance 5.9 320hp ....1998. Bought just before the 380hp came out. Had the M1 dual plane on it when it was new. Still running the stock heads with upgraded valve springs from Hughes...just did a cam upgrade last winter with this one. I’d like to do an eddy head upgrade at some point. Be aware the lift on this cam is fairly high for stock magnum heads. Measured carefully for clearance and Hughes said it wouldn’t be a problem. So far so good to 5800rpm. This is the highest lift cam they recommended to me for stock heads. Runs very well for me with a 46rh and 3.55’s with good street manners. Research for what you want and other components your running is key to cam selection for sure.

The M1 single plane operating range is the “sweet spot” but it works fine on the street.

Why is it all torn down now; major changes or just little stuff?

RammerJammer75 shows how well the bypass hose will work in his second picture. Nice picture.

Just for reference, I will attach a picture of an M1 dual plane for Magnum heads and with Magnum bypass hose and thermostat.

View attachment 1715625159

Way different from mine.

Bobzilla

Well-Known Member

Yup. Mine is Magnum intake bolt pattern, Magnum thermostat location and size, and Magnum bypass hose.

Yours is the same basic manifold with Magnum intake bolt pattern, LA thermostat location and size, and LA bypass hose.

The M1 manifolds had quite vast array of configurations. Too bad they discontinued all of these. They are good pieces.

Note: this response was just to detail these configurations for anyone looking for info on one of these intakes. There was also LA intake bolt pattern with either LA or Magnum thermostat and bypass hose as well. Then, all of these configurations were available in single plane both with and without fuel injection bosses in each runner. Lots of part numbers.

Last edited:

That’s for sure! A lot of changes for the same parts over the years sometimes.

Hey @Six Barrel Bill did you get the daughter's car going?

Six Barrel Bill

Well-Known Member

Not quite yet. You know how it is, it's a ton of work. All kinds of little problems to solve. The biggest issue at the moment is the right side of the Doug's s ceramic coated headers wants the same space as the torsion bar. They sent me a new one but I haven't tried it yet. We've also decided that since the clearance is so dang tight with the headers, we're going to have to run solid mounts. The MSD distributor wants the same space as the variable speed wiper so I've had to convert that to a two-speed wiper and it just barely fits.Hey @Six Barrel Bill did you get the daughter's car going?

Every nut and bolt has been touched, the engine and trans have been dropped in (well the body was dropped on). And right now I'm rewiring the entire car. We went with the American Auto wire upgrade kit, it's really nice.

Six Barrel Bill

Well-Known Member

I temporarily installed the dash over the weekend so I could start wiring up to the rear of the car. Here are some other pics along the restoration way.

Whoa! Looking good there buddy! Looking good.

Six Barrel Bill

Well-Known Member

Thanks man! There are definitely days I just want to give up cuz I'm so frustrated, but we're so far along I can't give up. Just got to get this thing done!Whoa! Looking good there buddy! Looking good.

@Six Barrel Bill

Your approaching the finish line with what I can only describe in one word because it fits and it is exactly what I see and no other word seems to be more fitting to describe what I see as this one singular word on your work.

Outstanding!

Finish that puppy up and drive the ever living socks out of it!

Your approaching the finish line with what I can only describe in one word because it fits and it is exactly what I see and no other word seems to be more fitting to describe what I see as this one singular word on your work.

Outstanding!

Finish that puppy up and drive the ever living socks out of it!

DionR

Well-Known Member

I see EFI now, too. What system are you running?

Six Barrel Bill

Well-Known Member

LOL, yeah she decided she didn't want a carburetor. That's the way I would have done it.I see EFI now, too. What system are you running?

Anyway, this is the Edelbrock ProFlow 4 system. We had to mill each side of the intake .060 (thickness of the gasket) because it didn't want to sit right with the aluminum Trick Flow heads. But once we did that everything went together very well.

Last edited:

Often is such the case. It’s not the intake by itself but the cumulative machining here there and everywhere. I had to take the same amount off of the wife’s intake and I did mine .070. This mainly comes from milling the deck. Also the cylinder heads. Head gasket thickness also has a play. These three things will stack up to make part fitment an issue every time. Standard expected fodder for engine building.

Six Barrel Bill

Well-Known Member

Yeah that was a little disappointing but I've come to expect it with this engine and especially this car. Nothing just bolts up.Often is such the case. It’s not the intake by itself but the cumulative machining here there and everywhere. I had to take the same amount off of the wife’s intake and I did mine .070. This mainly comes from milling the deck. Also the cylinder heads. Head gasket thickness also has a play. These three things will stack up to make part fitment an issue every time. Standard expected fodder for engine building.

The engine should run pretty hard. The best part is my machinist had us come over and my daughter and I assembled this thing. I ground every compression ring to fit on while my daughter assembled all the oil rings. We assembled and torqued everything. Enlarged oil galleys and even blueprinted. I sure hope it runs!

Wow, that’s a **** ton of work and take time to blue print an engine. Though I’d say knowing every little thing is great.

Just be careful of your timing and know your going to use 93 octane. Your not going to be able to run a lot of advance at your compression ratio and that tiny cam.

My build on the wife’s car is the same as yours with a Hyd roller cam @224@050. It’s an LA cam. The lift goes to .570-something with the 1.6 rockers

You may have to feed that some race fuel.

Once ironed out, that’ll be one snappy engine.

My build on the wife’s car is the same as yours with a Hyd roller cam @224@050. It’s an LA cam. The lift goes to .570-something with the 1.6 rockers

You may have to feed that some race fuel.

Once ironed out, that’ll be one snappy engine.

-