OK , where do I start?? LOL

Player1up - I bought this oil pan, Summit Brand P# G3536

http://www.summitracing.com/parts/sum-g3536/overview/make/dodge/year/1974/model/dart

and this pickup - P# MEL-72-S2

http://www.summitracing.com/parts/mel-72-s2/overview/year/1974

Fuel System - I haven't quite started on the fuel system yet, and my plans have changed thanks to some tasty Items I picked up at a recent swap meet and also at the pick-a-part the other day.

Oil Pan -

So here is a pic of the oil pan off with the new pickup installed. I did have to remove the oil pump to install the pickup just fyi. I may regret it, but I went budget conscious and bought the 4 piece oil pan gaskets. It does have to be a LA A body 360 oil pan for any of the magnum motors.

Note, I made a small mistake, the holes for the rubber gaskets where the nipple goes in the pan, one of these was not big enough, I should have drilled it out a smidge, but I tried to pull the nipple through anyway and broke it. I got it lined up carefully anyway, but it could create a problem later on down the line with an oil leak.

and with the new pan on, note the pics are from different sides of the motor.

Torque Converter/Flywheel

My plan of attack to modify the flywheel started with getting the motor back on the hoist and off the engine stand. I Then got the motor braced and sitting on the ground (with tension on the hoist to not hurt the oil pan. I then got the

904 converter (2800 stall) and centered the nub of the converter in the crank. I basically rotated, then finger tightened a converter bolt in, and would look see for alignment on 2 more of the bolts. It took me a few attempts to rotate for correct alignment. Once I achieved correct alignment and finger tightened of 3 out of 4 bolts, I marked both the converter and the fly wheel at the misaligned bolt hole. (This would have been a pain if the trans was attached, plus modifying would have prob of been impossible.)

Oh, for those who do not know, the Magnum motors, the flexplate is balanced and not the converter. So you will need a neutral balance torque converter, so if you have weights on your converter for a 904/727, they simply just need to be removed.

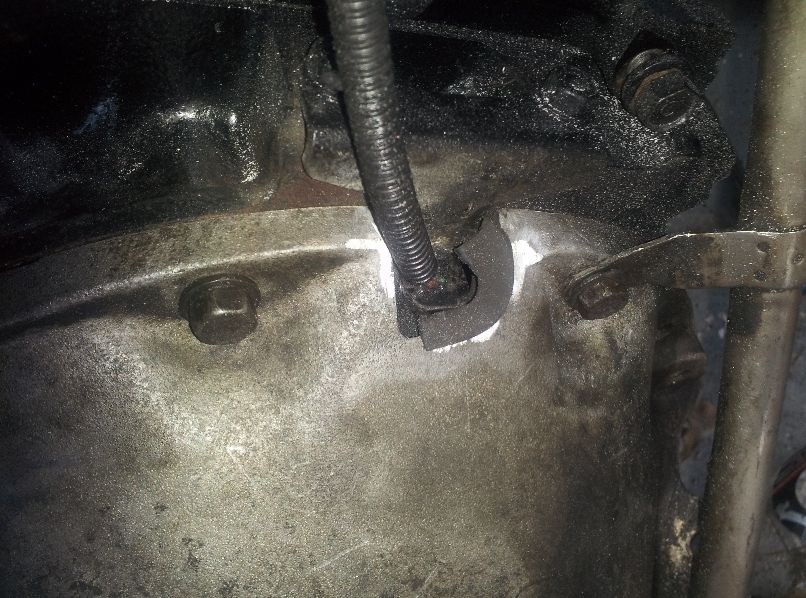

Here is a pic I took of the misalignment of the torque converter and the flex plate. This way I was able to see which direction that I needed to elongate the bolt hole in the flexplate. Of course you want to go towards the direction of the converter bolt hole. This pic is looking from the front of the flexplate.

At a trip to Harbor Freight tools, I found the perfect tool to elongate the hole on the flex plate. It is a type of drill bit made for "hogging" or drilling sideways. They usually come in a set of 3, I forgot to take a pic of the packaging. But it looks like this, and was about 8 bucks.

I took The converter off, and used this bit with my electric drill to elongate the hole. It's not pretty, but it worked extremely well, took about to minutes to modify the flexplate. Note picture below is from the back of the flexplate/torque converter side

since I marked the misaligned holes before, I simply did a test fit and now all 4 converter bolts are aligned and and able to be tightened up!