You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

6.1 Hemi 69 Barracuda Fastback Father Son Project

- Thread starter 'Cuda_ragtop

- Start date

-

'Cuda_ragtop

Woulda, Shoulda, 'Cuda!

I've been asked about my hinge conversion by a number of folks lately so I am recapping it here.

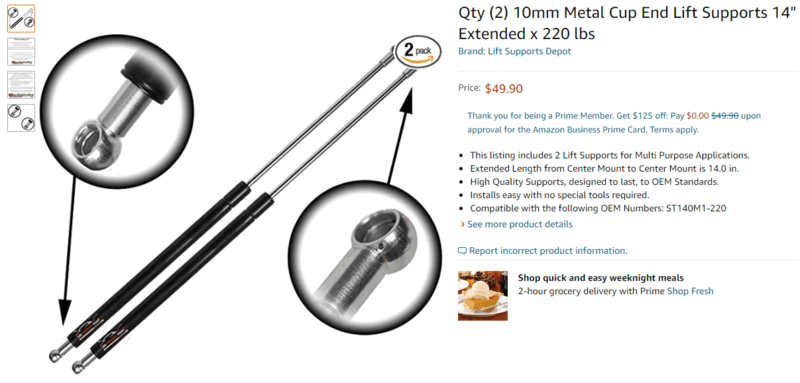

Have since switched out the struts to 220 lb. struts.

Since my original strut install used 15" fully extended struts, extended the length of these by 1 inch, so I would not have to change the bottom mounting location and still have the hood open all the way.

I added one of these per strut

Plus one of these per strut, made my 220 lb. 14" struts into 15" struts. Easy Peasy.

If you are seeing this for the first time, here is the rest of the hardware I used.

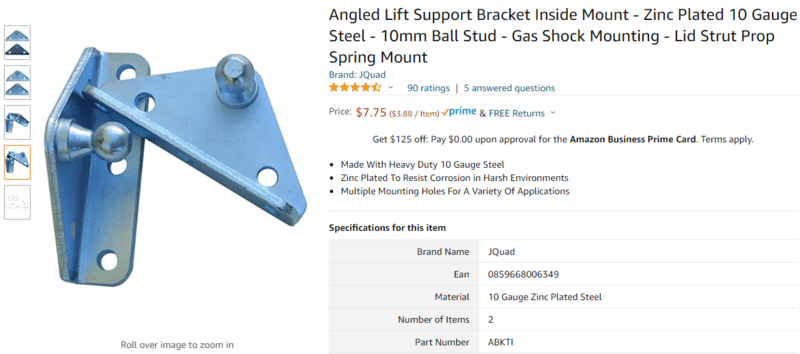

These for the bottom mount, Through bolted in both directions. No self tapping sheet metal screws here.

There is a lot of force load on these constantly... Screws would eventually loosen or worse, tear out.

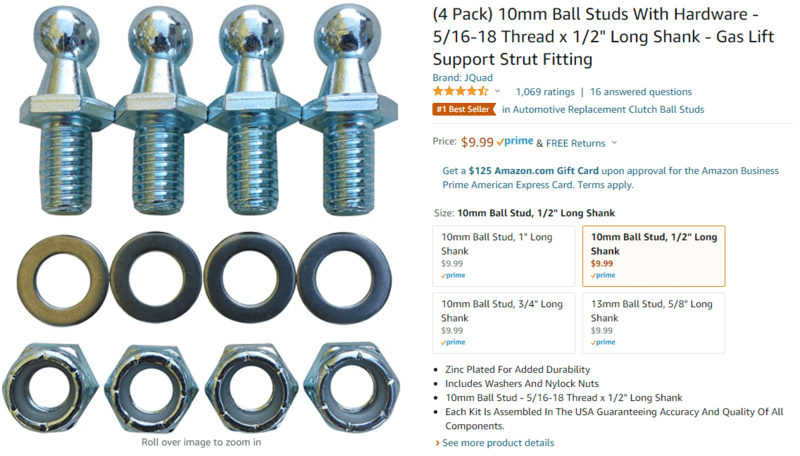

These for the top, using the hole where I drilled out the factory rivet.

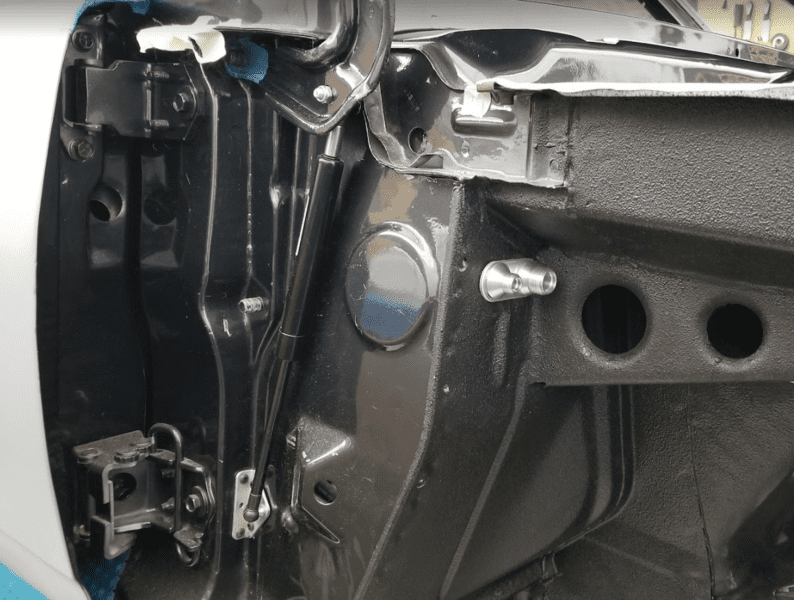

Looks like this now. Quiet. Smooth. No deflection. Opens nice. Closes nice.

Button Head, Allen socket, Machine screws with nuts and lock washers in the corner, in both directions.

The bottom mount is very solid here. No flexing. No worries.

Grease the **** out of your existing hinge springs, if you haven't already tried that...

One of my original springs broke.

You don't want to be close to one when it lets go!

They only need to lift about 3.5" from hood down to hood fully opened.

I installed them fully extended with the hood propped all the way open.

Landed the bottom brackets where they happened to be.

With the hood down the struts are still partially extended... not fully compressed.

The specs below are from the seller.

View attachment 1715377489

Have since switched out the struts to 220 lb. struts.

Since my original strut install used 15" fully extended struts, extended the length of these by 1 inch, so I would not have to change the bottom mounting location and still have the hood open all the way.

I added one of these per strut

Plus one of these per strut, made my 220 lb. 14" struts into 15" struts. Easy Peasy.

If you are seeing this for the first time, here is the rest of the hardware I used.

These for the bottom mount, Through bolted in both directions. No self tapping sheet metal screws here.

There is a lot of force load on these constantly... Screws would eventually loosen or worse, tear out.

These for the top, using the hole where I drilled out the factory rivet.

Looks like this now. Quiet. Smooth. No deflection. Opens nice. Closes nice.

Button Head, Allen socket, Machine screws with nuts and lock washers in the corner, in both directions.

The bottom mount is very solid here. No flexing. No worries.

Grease the **** out of your existing hinge springs, if you haven't already tried that...

One of my original springs broke.

You don't want to be close to one when it lets go!

Joe Mc

No Car Like A MoPar!

Thanks for all info and pictures.

Questions:

1-The socket on shock end threads off? Not sure how/where you used the 1" threaded extension? On picture it looks to be on the top/hood end of shock.

Maybe just me not quite sure of that particular detail?

2-If ever the shocks need to be replaced how difficult would that be?

I have a hard tonneau on my truck and over the 21 years I've owned it I've replaced the shocks 3 times and recently one just failed so...

BTW when I bought 1st replacement set guy at the truck center told me to make sure the extending shaft faces up otherwise the oil would prematurely leak.

Very nice execution

Questions:

1-The socket on shock end threads off? Not sure how/where you used the 1" threaded extension? On picture it looks to be on the top/hood end of shock.

Maybe just me not quite sure of that particular detail?

2-If ever the shocks need to be replaced how difficult would that be?

I have a hard tonneau on my truck and over the 21 years I've owned it I've replaced the shocks 3 times and recently one just failed so...

BTW when I bought 1st replacement set guy at the truck center told me to make sure the extending shaft faces up otherwise the oil would prematurely leak.

Very nice execution

'Cuda_ragtop

Woulda, Shoulda, 'Cuda!

Thanks for all info and pictures.

Questions:

1-The socket on shock end threads off? Not sure how/where you used the 1" threaded extension? On picture it looks to be on the top/hood end of shock.

Maybe just me not quite sure of that particular detail?

2-If ever the shocks need to be replaced how difficult would that be?

I have a hard tonneau on my truck and over the 21 years I've owned it I've replaced the shocks 3 times and recently one just failed so...

BTW when I bought 1st replacement set guy at the truck center told me to make sure the extending shaft faces up otherwise the oil would prematurely leak.

Very nice execution

I only extended the length because I went from 15" to 14" to get the 220 lb. struts. Yes, the ball socket unscrews. That is how I made my 14" into 15".

If you start with 14", you won't need to extend them... Just place the bottom Ball stud up an inch higher.

Manufacturer recommends shaft down to keep the seal oiled and prevent the seal drying out.

If I ever have to replace, I will only have to remove the splash shield.

Been in there a few times with the fender on. Had the hinges on and off with the fenders on. That's not fun but it is doable. Will be easier to do with the struts.

Joe Mc

No Car Like A MoPar!

Got it thanks

moparmat2000

Well-Known Member

Thank you for the great write up on the hood struts. I would bet if you rounded up the parts, and made kits with instructions including pix with measurements, you could sell this.I've been asked about my hinge conversion by a number of folks lately so I am recapping it here.

Have since switched out the struts to 220 lb. struts.

View attachment 1715847365

Since my original strut install used 15" fully extended struts, extended the length of these by 1 inch, so I would not have to change the bottom mounting location and still have the hood open all the way.

I added one of these per strut

View attachment 1715847367

Plus one of these per strut, made my 220 lb. 14" struts into 15" struts. Easy Peasy.

View attachment 1715847370

If you are seeing this for the first time, here is the rest of the hardware I used.

These for the bottom mount, Through bolted in both directions. No self tapping sheet metal screws here.

There is a lot of force load on these constantly... Screws would eventually loosen or worse, tear out.

View attachment 1715847372

These for the top, using the hole where I drilled out the factory rivet.

View attachment 1715847376

Looks like this now. Quiet. Smooth. No deflection. Opens nice. Closes nice.

View attachment 1715847378

Button Head, Allen socket, Machine screws with nuts and lock washers in the corner, in both directions.

The bottom mount is very solid here. No flexing. No worries.

Grease the **** out of your existing hinge springs, if you haven't already tried that...

One of my original springs broke.

You don't want to be close to one when it lets go!

Agrees.Thank you for the great write up on the hood struts. I would bet if you rounded up the parts, and made kits with instructions including pix with measurements, you could sell this.

Saw your link on fb about the hood struts, after reading that, I decided to just read through your whole build. Very impressive!

'Cuda_ragtop

Woulda, Shoulda, 'Cuda!

Thank you for the great write up on the hood struts. I would bet if you rounded up the parts, and made kits with instructions including pix with measurements, you could sell this.

Thanks MM2K!

I linked to this page for a couple of A-Body FB groups and there are a surprising number of people that think the stock hood hinge clock springs never wear out or fail... “¯\_(ツ)_/¯“

They ask, "Why would anyone replace the 50+ year old springs, they never fail?"

Or, "Those will be fun to change when they fail and your fender is back on."

Yes, they do break. I was a witness to one failing in person, mine. Believe me when I say, you really do not to be up close to one when it decides to let go. An incredible amount of tension is stored in one of those springs under load. That is what lead me to this solution.

In case anyone was wondering, they are super easy to change...

Just have to remove the dust shield and can be done with the fenders on the car.

Much easier than replacing one of those springs. Been there, done that too.

Unscrew the strut from the socket at the top instead of removing it from the ball stud.

Very easy to remove the bottom socket from the ball stud.

'Cuda_ragtop

Woulda, Shoulda, 'Cuda!

Thanks for all info and pictures.

Questions:

1-The socket on shock end threads off? Not sure how/where you used the 1" threaded extension? On picture it looks to be on the top/hood end of shock.

Maybe just me not quite sure of that particular detail?

2-If ever the shocks need to be replaced how difficult would that be?

I have a hard tonneau on my truck and over the 21 years I've owned it I've replaced the shocks 3 times and recently one just failed so...

BTW when I bought 1st replacement set guy at the truck center told me to make sure the extending shaft faces up otherwise the oil would prematurely leak.

Very nice execution

I took another look, definitely want to be at least 15" long to be able to get your finger on the bottom nuts on the inside... 16" would work too. 14" will put a couple of the inside nuts in a tough spot for access.

Another option would be Nutzerts, aka Riv-nuts... then 14" without the +1" extension would be fine. I might have done it that way myself if I had though of it back then. “¯\_(ツ)_/¯“

Maybe next time.

'Cuda_ragtop

Woulda, Shoulda, 'Cuda!

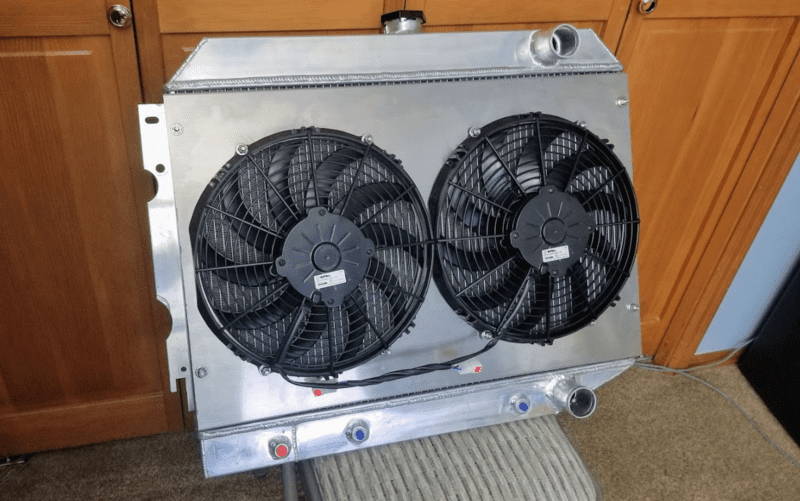

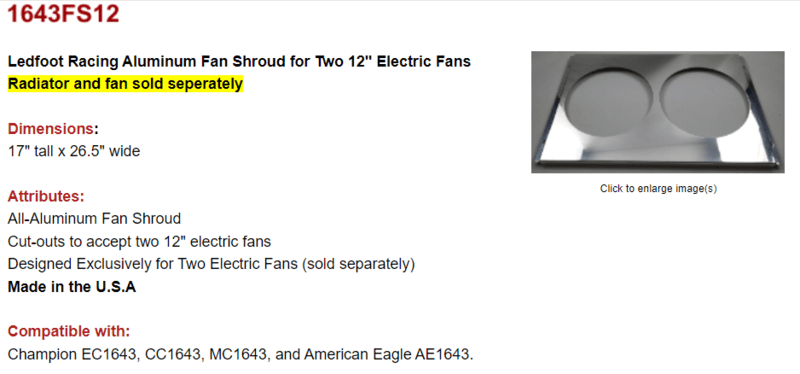

Slow going lately... I did cut bigger (12") holes in the fan shroud.

Trimmed off a little of the shroud edges to fit it as close to the radiator as possible and still leave about half an inch of clearance. I cut slots into the radiator's shroud mounting surface so I could use 1/4-20 stainless bolts to attach the shroud to the radiator.

Used the same 1/4-20 x 3/4" hex head bolts to attach the fans to the shroud.

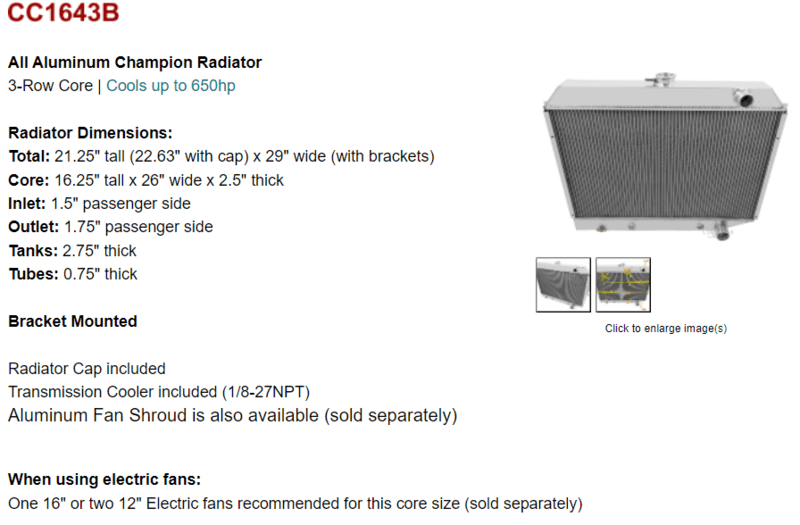

Champion Radiator PN# CC1643B - 21 3/4" x 21 3/4" x 3 1/8" with 26"x17" Core

Champion Shroud PN#1643FS12

I ordered the radiator directly from champion but I had them replace the 1.5" inlet with a 1.75" inlet to match the size of the thermostat opening. I figured if it was going to need a 1.75" hose, it might as well fit on both ends. “¯\_(ツ)_/¯“

Our car has US Car Tool's Full Core Support set up with the opening to fit the 26" wide Champion Core width.

I was originally going to try a single 16" fan but it was only 1600 CFM and the 12" Spal fans are 1328 + 1328 or 2656 CFM combined. Will set them up for 1 or 1+1 based on demand.

Oh, and the 12" fans have more clearance from the front of the engine than the singe 16" in our car, by a couple inches. I like that a lot more too.

It's sitting in my office right now, as I have been working on it and test fitting it all together before I paint it all black.

Disassembled the original stock gas pedal assembly, cleaned, painted and reassembled it.

Trimmed off a little of the shroud edges to fit it as close to the radiator as possible and still leave about half an inch of clearance. I cut slots into the radiator's shroud mounting surface so I could use 1/4-20 stainless bolts to attach the shroud to the radiator.

Used the same 1/4-20 x 3/4" hex head bolts to attach the fans to the shroud.

Champion Radiator PN# CC1643B - 21 3/4" x 21 3/4" x 3 1/8" with 26"x17" Core

Champion Shroud PN#1643FS12

I ordered the radiator directly from champion but I had them replace the 1.5" inlet with a 1.75" inlet to match the size of the thermostat opening. I figured if it was going to need a 1.75" hose, it might as well fit on both ends. “¯\_(ツ)_/¯“

Our car has US Car Tool's Full Core Support set up with the opening to fit the 26" wide Champion Core width.

I was originally going to try a single 16" fan but it was only 1600 CFM and the 12" Spal fans are 1328 + 1328 or 2656 CFM combined. Will set them up for 1 or 1+1 based on demand.

Oh, and the 12" fans have more clearance from the front of the engine than the singe 16" in our car, by a couple inches. I like that a lot more too.

It's sitting in my office right now, as I have been working on it and test fitting it all together before I paint it all black.

Disassembled the original stock gas pedal assembly, cleaned, painted and reassembled it.

Man I know it's gonna be a pain in the kiester but I'm going to look into doing this on my build... Love it, it looks so simple when finished!

One question. Maybe I missed it but why did you go from 180lbs to 220lbs on the struts?

One question. Maybe I missed it but why did you go from 180lbs to 220lbs on the struts?

'Cuda_ragtop

Woulda, Shoulda, 'Cuda!

Man I know it's gonna be a pain in the kiester but I'm going to look into doing this on my build... Love it, it looks so simple when finished!

One question. Maybe I missed it but why did you go from 180lbs to 220lbs on the struts?

I started with 150 as just a guess.

150 and 180 would hold the hood open, but I was concerned that a good stiff wind would possibly shut it on someone... maybe at a car show.

200 seemed to be pretty solid but I'm more confident with the 220 lb. struts there will be no accidental closings.

racerjoe

Well-Known Member

Mocked up QA1 Motor Mount Relocation.

Now to find someone to weld up a steel one and mod the TTi Mount to match.

View attachment 1715123953

Will match the TTi mount by relocating the biscuit mount surface the same distance towards the rear. Then remove the original QA1 mount completely. Could cut the QA mount and move it but I want to keep it there to match angles and be able to measure exactly how much to move the mount on the TTi mount to maintain the relative position of the engine mounting surface.

View attachment 1715123954

View attachment 1715123955

I'm liking how this is looking.

This is a fantastic idea. I may have to steal it as I feel like I'm on the path to start collecting parts for a G3 swap. (I already have the engine) I see you posted several pictures of the driver side with the headers. Any interference problems on the passenger side, particularly with your modified engine mount?

Thanks-

'Cuda_ragtop

Woulda, Shoulda, 'Cuda!

This is a fantastic idea. I may have to steal it as I feel like I'm on the path to start collecting parts for a G3 swap. (I already have the engine) I see you posted several pictures of the driver side with the headers. Any interference problems on the passenger side, particularly with your modified engine mount?

Thanks-

Passenger side really had zero clearance issues other than the oil filter which looks like an obvious natural fit now. I love all the clearance the QA1 K provides.

I've had the engine in and out with the headers on. Also installed the torsion bars while the headers were on, together with the 8HP70 to test fit. So far no clearance issues.

Tight clearance, valve cover to inner fender on the passenger side. Still fits though.

Trans tunnel is in, welded and body worked.

Marked up some more holes that won't be needed, to weld up in the engine compartment.

Hopefully I marked the right ones... I do know there is one with tape over it in the picture that I decided I should keep. Might use it for the Terminator X harness to pass through if it will fit...

racerjoe

Well-Known Member

Passenger side really had zero clearance issues other than the oil filter which looks like an obvious natural fit now. I love all the clearance the QA1 K provides.

I've had the engine in and out with the headers on. Also installed the torsion bars while the headers were on, together with the 8HP70 to test fit. So far no clearance issues.

Tight clearance, valve cover to inner fender on the passenger side. Still fits though.

Trans tunnel is in, welded and body worked.

Marked up some more holes that won't be needed, to weld up in the engine compartment.

Hopefully I marked the right ones... I do know there is one with tape over it in the picture that I decided I should keep. Might use it for the Terminator X harness to pass through if it will fit...

View attachment 1715880670

Thanks for your reply. I've seen some pictures on the TTI headers and mounts in their stock locations and it seemed like it would create an interference with the modification you did. I'm guessing it was just angle of the photo.

There's so many holes not needed if you aren't using factory insulation or AC/heater box. I used an aftermarket wiring harness so I didn't even need the bulkhead hole. All of my headlight, horn, etc. wiring is run in the fender well.

Take a look at Deutsch connectors for your EFI harness. With these, you will have a weather tight connection instead of a big hole. I did a Holley Sniper EFI installation on a friends car and the hole has to be quite large to fit all the connectors through it.

You can barely seem mine in this photo. Once the air filter is on, it's hardly noticeable.

'Cuda_ragtop

Woulda, Shoulda, 'Cuda!

Thanks for your reply. I've seen some pictures on the TTI headers and mounts in their stock locations and it seemed like it would create an interference with the modification you did. I'm guessing it was just angle of the photo.

There's so many holes not needed if you aren't using factory insulation or AC/heater box. I used an aftermarket wiring harness so I didn't even need the bulkhead hole. All of my headlight, horn, etc. wiring is run in the fender well.

Take a look at Deutsch connectors for your EFI harness. With these, you will have a weather tight connection instead of a big hole. I did a Holley Sniper EFI installation on a friends car and the hole has to be quite large to fit all the connectors through it.

You can barely seem mine in this photo. Once the air filter is on, it's hardly noticeable.

View attachment 1715880824

View attachment 1715880823

That is a nice clean look.

We decided to eliminate the cowl vents too, since the Classic Auto Air system does not use any outside air. It calls for closing off the passenger vent only but we eliminated both and smoothed the cowl area. Won't miss having the openings to collect needles, leaves water or anything else that typically gets collected in them.

Since the cowl vents are where the windshield washer nozzles normally are, we will install modern washer nozzles on the cowl. Will make use of the existing firewall nozzle holes to plumb the new nozzles.

Have a couple different styles. Will pick one based on spray pattern and best installation location.

I suppose they could go on the hood if we wanted but the cowl is the plan for now.

Both of these styles have nozzles that can be aimed.

I bought a pair that mount to the wiper blades too but already ruled those out.

I like that these use a nut to hold them in. I can reach up into the cowl from the inside through the opening under the dash to tighten them...

Here are a couple other views of the passenger side header.

'Cuda_ragtop

Woulda, Shoulda, 'Cuda!

Thanks for your reply. I've seen some pictures on the TTI headers and mounts in their stock locations and it seemed like it would create an interference with the modification you did. I'm guessing it was just angle of the photo.

There's so many holes not needed if you aren't using factory insulation or AC/heater box. I used an aftermarket wiring harness so I didn't even need the bulkhead hole. All of my headlight, horn, etc. wiring is run in the fender well.

Take a look at Deutsch connectors for your EFI harness. With these, you will have a weather tight connection instead of a big hole. I did a Holley Sniper EFI installation on a friends car and the hole has to be quite large to fit all the connectors through it.

You can barely seem mine in this photo. Once the air filter is on, it's hardly noticeable.

View attachment 1715880824

View attachment 1715880823

Do you have a wiper motor that is set up to work inside the smoothed firewall?

You can definitely fit a 6.4 with variable length intake runners with the flat firewall and no wiper motor in the engine bay.

racerjoe

Well-Known Member

Do you have a wiper motor that is set up to work inside the smoothed firewall?

You can definitely fit a 6.4 with variable length intake runners with the flat firewall and no wiper motor in the engine bay.

I have a wiper motor from a Dakota mounted on the inside. I was shocked at how easy the conversion was. The arm off the motor was the proper length so I didn't have to do any calculations to get the ratios correct. I also figured out the wiring so I could use my stock wiper switch. It's still a 2 speed, but the slow speed is faster than the stock fast speed.

One regret I have is not cutting the cowl louvers out and smoothing them over. There's no need for them at all. I do have the holes inside sealed.

Thanks for the extra pictures. I really like what you did. One of the major things that bugged me about the G3 swap was the darn remote oil filter. Now the only thing to figure out next is the AC compressor. I'd like to use the stock car pulley configuration, but I believe the stock AC compressor interferes with the TTI mount and maybe the K-member. I guess worse case is I use the mini compressor I have now and make a bracket.

DionR

Well-Known Member

Here are a couple other views of the passenger side header.

View attachment 1715881233

View attachment 1715881240

I always figured if I ever did this swap, I would start out with a /6 k-frame. It moves the right motor mount back, similar to what is shown. Not sure it moves it enough, it was just an idea I've had.

Seems like someone else was suggesting the same thing and might have done it, but no idea who that was.

DionR

Well-Known Member

Slick build, BTW. Love it.

Slant 6 K-Frame = LOTS of ClearanceI always figured if I ever did this swap, I would start out with a /6 k-frame. It moves the right motor mount back, similar to what is shown. Not sure it moves it enough, it was just an idea I've had.

Seems like someone else was suggesting the same thing and might have done it, but no idea who that was.

'Cuda_ragtop

Woulda, Shoulda, 'Cuda!

Sprung for the Lizard Skin Full Meal Deal...

Sound Control, Ceramic Insulation, Application Kit and Aerosol Top Coat.

Should make for a Cooler, Quieter Ride. Well, that's the plan anyway.

LizardSkin

Ordered 2 Gallons of Sound Control, 2 Gallons of Ceramic Insulation + the Top Coat and Application kit from Jeg's

Lizard Skin Insulation, Sound Dampener and Accessories - JEGS High Performance

Insulating quality of the Ceramic Coating is pretty impressive.

Firewall, Entire Floor and Tunnel, Roof and then as much of the rest of the car the 2 gallons will do.

It goes over the top of the Sound Control.

Lizard Skin Ceramic Insulation:

Lizard Skin Sound Control:

Sound Control, Ceramic Insulation, Application Kit and Aerosol Top Coat.

Should make for a Cooler, Quieter Ride. Well, that's the plan anyway.

LizardSkin

Ordered 2 Gallons of Sound Control, 2 Gallons of Ceramic Insulation + the Top Coat and Application kit from Jeg's

Lizard Skin Insulation, Sound Dampener and Accessories - JEGS High Performance

Insulating quality of the Ceramic Coating is pretty impressive.

Firewall, Entire Floor and Tunnel, Roof and then as much of the rest of the car the 2 gallons will do.

It goes over the top of the Sound Control.

Lizard Skin Ceramic Insulation:

Lizard Skin Sound Control:

72Duster440

Well-Known Member

Awesome build, I saw it on FB and the 8HP caught my interest. Looking to do one behind my big block.

'Cuda_ragtop

Woulda, Shoulda, 'Cuda!

Awesome build, I saw it on FB and the 8HP caught my interest. Looking to do one behind my big block.

Thanks!

BB Mopar to 8HP has been done. This the only one I know of though...

Lots of custom one off engineering, machining and fabrication in this build.

My 8HP70 swap.

Not aware of any retail swap "Kit" for 8HP to BB Mopar yet.

I would probably look into getting an 8HP90 (900 Nm) though for Big Block torque handling, vs 8HP70 (700 Nm) if you were not already thing that...

663.8 lb.-ft. HP90 vs 516 lb.-ft. HP70

-