No problem. I'd say it's a hazard as it is.Can you legally in Sweden remove the steering column lock the importer installed? You could fill the hole they made for it 1ith JB weld and bodywork it, or get another one from the States.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

66 Dart GT HT Whatsitgonnabe?

- Thread starter 360DartGT66

- Start date

-

The material didn't burn too fast so it wasn't that bad but, like I said, not having a sense of smell does cause some interesting situations from time to time.Ouch thats pretty scary. I was welding in the floor pans on my brothers monte carlo SS and was under the car when i lit my hair on fire LOL. I had much longer hair back then. My niece cuts hair for a living. I asked her to please fix my lopsided head of hair.

moparmat2000

Well-Known Member

I'd remove it and smooth out the column then. It looks pretty awful actually.No problem. I'd say it's a hazard as it is.

It's pretty low on my priority list, to be honest.I'd remove it and smooth out the column then. It looks pretty awful actually.

moparmat2000

Well-Known Member

Future project. You know these cars are never really done. Theres always something to tinker with.

Can you legally in Sweden remove the steering column lock the importer installed?

Yes, you can. The insurance companies I have been in touch with has never asked about the steering column lock or any other theft prevention items installed by the factory/importer.

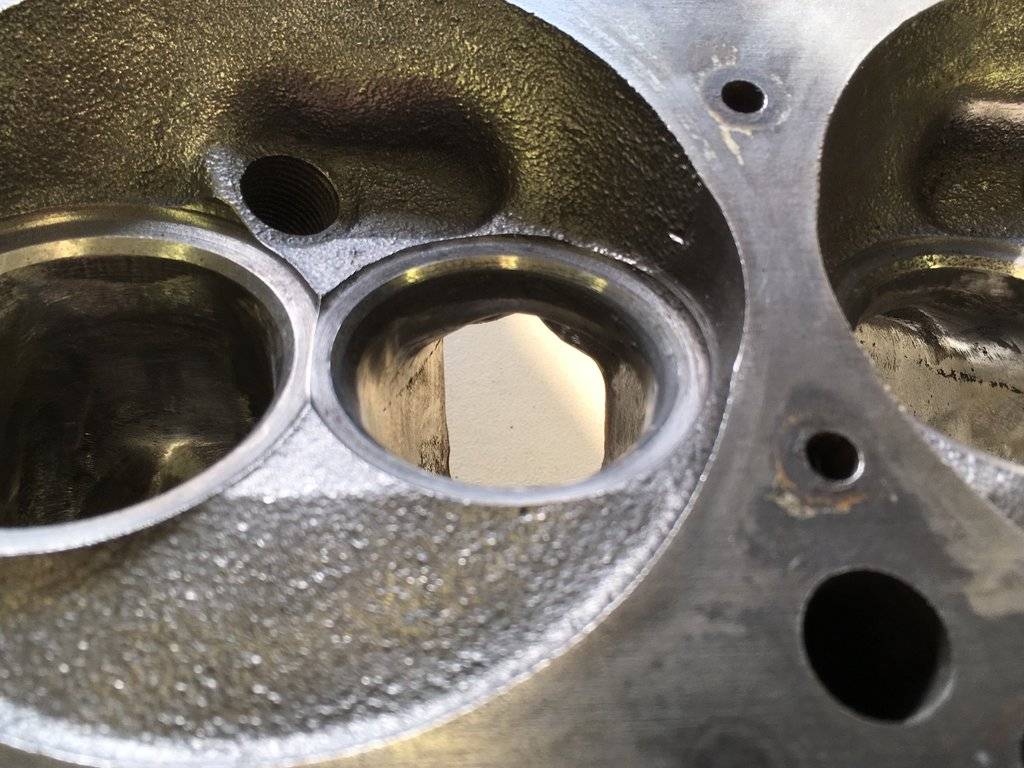

I got my ported iron heads (974 casting, 1975-76 stock 360) home last night. User @trebor75 spent 50 hours on them and I was lucky enough to pick them up and get a set of brand new exhaust valves included in the deal.

A brief examination revealed - as advertised - a couple of exhaust valve guides that need replacing. I'm not sure how that works but I guess they're press fit? Or are they shrink fit? Anyone?

Since these don't need to be finished any time soon, I'm considering putting 2.02 intake valves in but that will depend on cost. I wouldn't know where to turn to get that done, either, except a normal mechanical shop. I have no idea whether there are any shops with american iron experience around here. I'll ask around, of course, but for now, I'll be focusing on doing some finishing touches, perhaps, and look into those valve guides.

I'm really happy to have them, Trebor, thanks, and good luck with your Edelbrock setup!

Here are some pics I took before packing them into my little carry-on suitcase that actually survived being dragged across Stockholm Central and the walk home from the local train station with a 100 pound load.

A brief examination revealed - as advertised - a couple of exhaust valve guides that need replacing. I'm not sure how that works but I guess they're press fit? Or are they shrink fit? Anyone?

Since these don't need to be finished any time soon, I'm considering putting 2.02 intake valves in but that will depend on cost. I wouldn't know where to turn to get that done, either, except a normal mechanical shop. I have no idea whether there are any shops with american iron experience around here. I'll ask around, of course, but for now, I'll be focusing on doing some finishing touches, perhaps, and look into those valve guides.

I'm really happy to have them, Trebor, thanks, and good luck with your Edelbrock setup!

Here are some pics I took before packing them into my little carry-on suitcase that actually survived being dragged across Stockholm Central and the walk home from the local train station with a 100 pound load.

Oh, and I'm fantasizing about doing a T/A-style push rod relocation to get rid of that intake port hump. Is that a super bad idea?

moparmat2000

Well-Known Member

Not sure about the pushrod relocation idea. You may be able to move them, then clean out the hump. There may not be enough material there to do this. Thats why i think the T/A heads were different castings.

Good score by rhe way. Valve guides on these are a press fit, then the hole for the valve stem is machined for proper stem clearance. I would imagine a good machine shop could fix em up for you. Here in the states our machine shops are used to seeing american and foreign. I think all they really need is the specifications it needs to be, and the parts.

A buddy of mine years ago had a 1981 motoguzzi 1000 SP. Had to get the crank balanced for his new rods, and pistons, also needed a valve job on the heads. A local auto machine shop fixed him right up despite never messing with one of those before. He gave em all the specs in metric, and away they went. Everything came back perfect.

Good score by rhe way. Valve guides on these are a press fit, then the hole for the valve stem is machined for proper stem clearance. I would imagine a good machine shop could fix em up for you. Here in the states our machine shops are used to seeing american and foreign. I think all they really need is the specifications it needs to be, and the parts.

A buddy of mine years ago had a 1981 motoguzzi 1000 SP. Had to get the crank balanced for his new rods, and pistons, also needed a valve job on the heads. A local auto machine shop fixed him right up despite never messing with one of those before. He gave em all the specs in metric, and away they went. Everything came back perfect.

If I can just get my hands on a press, I think I could get the guides out and new ones in. I'd do all 16, I think. I guess the internet knows what diameter the broach needs to be.Not sure about the pushrod relocation idea. You may be able to move them, then clean out the hump. There may not be enough material there to do this. Thats why i think the T/A heads were different castings.

Good score by rhe way. Valve guides on these are a press fit, then the hole for the valve stem is machined for proper stem clearance. I would imagine a good machine shop could fix em up for you. Here in the states our machine shops are used to seeing american and foreign. I think all they really need is the specifications it needs to be, and the parts.

A buddy of mine years ago had a 1981 motoguzzi 1000 SP. Had to get the crank balanced for his new rods, and pistons, also needed a valve job on the heads. A local auto machine shop fixed him right up despite never messing with one of those before. He gave em all the specs in metric, and away they went. Everything came back perfect.

I'm not sure push rod relocation is possible on these heads either. It would depend on if there's any water jacket in that area. otherwise, it would just be a matter of removing material where the push rod needs to be and filling up the old hole, either by pressing in a rod or just JB weld. I know Steve Dulcic of Hot Rod Magazine used JB weld to do it on a set of Edelbrock alu heads. He had to move the intake mounting hole, though, which might be additional hassle.

I haven't looked close enough at the heads yet, we'll see whet happens. I'm on a budget, though, so buying time at a machine shop might be difficult. The ones I know of have all expensive CNC equipment only so time in those is expensive.

Who sells valve guides, btw?

moparmat2000

Well-Known Member

Wow, all my machine shops over here are old skool manual machines, even the head milling machine is old skool. Not sure what you would use a CNC machine for on cylinder heads especially grinding seats.

Well, none of the machine shops I know of actually do this kind of work, they do production. That's my problem.Wow, all my machine shops over here are old skool manual machines, even the head milling machine is old skool. Not sure what you would use a CNC machine for on cylinder heads especially grinding seats.

There is one shop nearby that might actually be that kind of shop. I'm going to check it out one of these days.

I scored a large compressor the other day. It is unfortunately also up in the Stockholm area. It has a broken connecting rod so we'll see where that goes once I get it home and apart.

I'm looking into the whole valve guide and seat situation. If my dad's old business partner still has any milling machines or arbors, then maybe he'll be able to help me machine out the valve guides and exhaust valve seats. I'm thinking that I might put hardened exhaust seat inserts in and go to 2.02 valves if I'm going to machine the heads. Maybe deck them, too.

I know decking requires intake work but I think I can get my hands on an intake pretty cheap.

Did anyone here do seat inserts? Any tips and pointers? Go to 2.02 valves?

I'm looking into the whole valve guide and seat situation. If my dad's old business partner still has any milling machines or arbors, then maybe he'll be able to help me machine out the valve guides and exhaust valve seats. I'm thinking that I might put hardened exhaust seat inserts in and go to 2.02 valves if I'm going to machine the heads. Maybe deck them, too.

I know decking requires intake work but I think I can get my hands on an intake pretty cheap.

Did anyone here do seat inserts? Any tips and pointers? Go to 2.02 valves?

moparmat2000

Well-Known Member

What year is the castings? When everything went unleaded fuel in the states around 1977 i think the seat areas were locally hardened for the no lead fuel. Trucks didnt require unleaded fuel till 1979, but i would imagine they would have treated all the heads the same way on manufacturing.

Last edited:

As a matter of course any head I send to the machine shop to get reconditioned, it gets hardened exhaust seats. 2.02 intake valves would be perfect for your 360!

I imagine that hardened zone is rather thin and the seats where the guides are completely worn out need to be milled down at least 0.040".What year is the castings? When everything went unleaded fuel in the states around 1977 i think the seat areas were locally hardened for the no lead fuel. Trucks didnt require unleaded fuel till 1979, but i would imagine they would have treated all the heads the same way on manufacturing.

Since hardened inserts are available for $3.50, I'm thinking I might as well put some in when they are up in the mill and not get the valves sunk in the head either.

I suppose they are shrink fit? Just heat the head up and hold the inserts in place until they heat up, I guess?

moparmat2000

Well-Known Member

Not sure how they go in. Prob chill to shrink, then press in. Good idea to add them though, since they do seem cheap enough to buy. Its the machining that costs lol.

I thought today, Friday the 13:th would be as good a day as any to report on a little 'progress'.

First of all, I got this big monster of an air compressor home last weekend. It's got a 275 liter tank and a 7 hp motor. The 2-cylinder 1-stage compressor has a broken connecting rod and I'm debating whether to get a new unit alltogether or try and make a new rod.

I've disassembled it (it was the only way I could get it out of the car on my own) and I'm planning on getting the tank cleaned up this weekend. It might turn out to be a no-go because of a major birthday event on Sunday (our youngest just turned six) but I'll try.

Also, I called a local engine shop. They were fully booked but pointed me to two other shops in the area. I called one of them this afternoon and to my great surprise, new guides isn't going to cost me the $1,000 I was afraid of bit more like $300 for the pair. A set of hardened seats is roughly $60 per head. Materials not included.

I need to call the guy again on Monday - he was kind of busy - but I intend to supply him with the material which I hope is ok.

This raises the important question: Should I go to 5/16" stem valves or is that just stupid? I'll be needing new intake valves anyway (2.02 ) so I'm free to choose whichever stem I like.

) so I'm free to choose whichever stem I like.

Here's the compressor, btw.

First of all, I got this big monster of an air compressor home last weekend. It's got a 275 liter tank and a 7 hp motor. The 2-cylinder 1-stage compressor has a broken connecting rod and I'm debating whether to get a new unit alltogether or try and make a new rod.

I've disassembled it (it was the only way I could get it out of the car on my own) and I'm planning on getting the tank cleaned up this weekend. It might turn out to be a no-go because of a major birthday event on Sunday (our youngest just turned six) but I'll try.

Also, I called a local engine shop. They were fully booked but pointed me to two other shops in the area. I called one of them this afternoon and to my great surprise, new guides isn't going to cost me the $1,000 I was afraid of bit more like $300 for the pair. A set of hardened seats is roughly $60 per head. Materials not included.

I need to call the guy again on Monday - he was kind of busy - but I intend to supply him with the material which I hope is ok.

This raises the important question: Should I go to 5/16" stem valves or is that just stupid? I'll be needing new intake valves anyway (2.02

Here's the compressor, btw.

That is definitely a big setup!

Yes. Took three guys to load it in the car. Once I too the motor and the compressor unit off, it wasn't so bad. There was probably fifteen gallons of water in it, too.That is definitely a big setup!

15 gal of water = another 120 lbs on top of the weight of the tank - still wasn’t good!

I think my conversion was off there, I think ten gallons is closer to the truth. 30 liters. No, wait. Still off. Eight?15 gal of water = another 120 lbs on top of the weight of the tank - still wasn’t good!

It makes my head spin trying to convert all those gal to liters and how much it all weighs in kilos - anyway you look at it, all that extra water makes it heavy!

It sure added a few pounds.It makes my head spin trying to convert all those gal to liters and how much it all weighs in kilos - anyway you look at it, all that extra water makes it heavy!

Oh, once you're in liters, kilograms is easy. It's 1:1.

-