Looks like you are doing thoughtful, skillful good work on this. Please be aware that the exterior lights have to work properly in all respects -- eyeballing it, even with an expert eye, and assessing it "Yep, looks good!" isn't enough to guarantee adequate safety performance from homemade vehicle lights. It sounds like you're building these for your own car and not for production and commercial sale; I'm not suggesting you have to go to the trouble and expense of sending your lamps for compliance testing (though liability with uncertified safety lights is an issue worth keeping in mind), but you should at least be aware of the factors that go into whether a brake light, tail light, parking light, turn signal or other safety light works adequately.

•Rear intensity in dim tail mode (2cd minimum on axis, 18cd maximum anywhere in the beam)

• Rear intensity in bright brake mode (80cd minimum on axis, 300cd maximum anywhere)

• Front intensity in dim park mode (4cd minimum on axis, 125cd maximum anywhere)

• Front intensity in bright turn mode (200cd minimum on axis, no maximum)

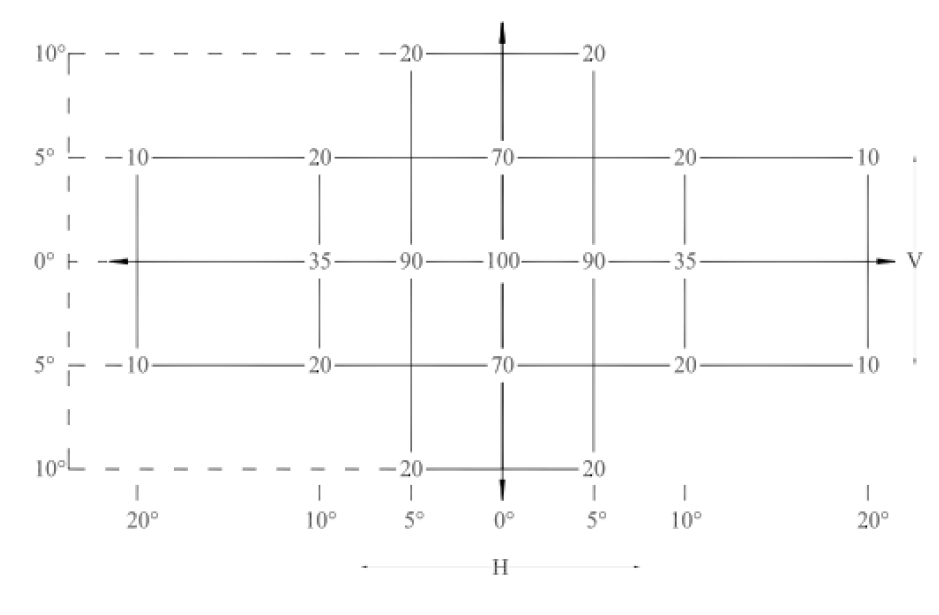

•Intensity throughout the required spread range of vertical and horizontal angles; multiply the minimum requirement by the percentage values in this table to get the requirements for the various test angles:

You can see the center of the grid is "100", that represents 100% of the axial minimum intensity values listed above. At 5° left and 5°right on the horizontal, you need 90% of the minimum axial intensity value. At 10°left and 10° right on the horizontal, you need 35% of the axial minimum, and so on. These requirements are so that the lights convey their message accurately and unambiguously to drivers located anywhere within relevant seeing range...up high in a semi tractor, down low in a Corvette, one or two lanes over or approaching on an on-ramp, etc.

• Intensity ratio, bright:dim. The brake (or front turn) lamp must give at least three times the intensity of the tail (or front parking) light, except on axis as well as 5°left and right on the horizontal and 5° up on the vertical, at which points the brake (or front turn) lamp must give at least five times the intensity of the tail (or front parking) lamp. This is important so that other drivers can immediately discern whether they're seeing a brake light or a tail light, or a turn signal or a parking lamp, without having to spend seconds watching the state change (bright to dim or dim to bright).

•Intensity maintenance at high and low ambient temperatures and with prolonged use. This is a toughie; LEDs' light output increases with decreasing temperature, and decreases with increasing temperature. You need to design your driver circuitry such that the lamps will produce light within the correct intensity ranges no matter how cold or hot it is outside, and the brake lights will remain above the minimum requirement even in traffic with extended usage. Either you need to seriously underdrive the emitters or you need very good heat sinking.

Please keep us up to date on how this project evolves