You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

8.8 swap

- Thread starter dart360swinger

- Start date

-

moparmat2000

Well-Known Member

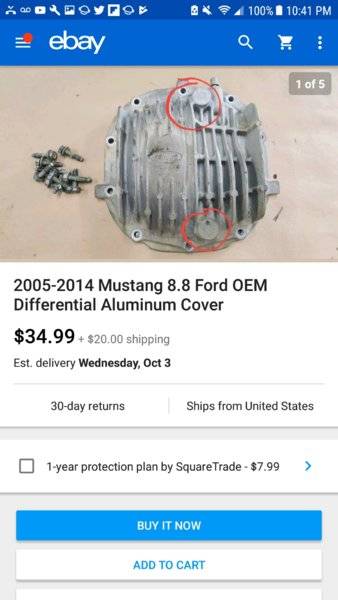

This ones off of a GT500. same part as ford motorsports one ,except bosses i circled in red arent drilled and tapped for fill or drain plugs like the motorsports one is. Easy fix though.

moparmat2000

Well-Known Member

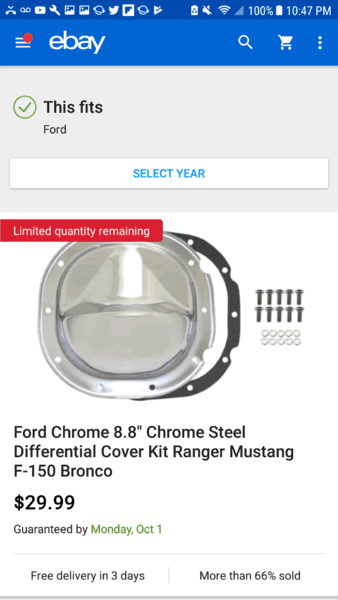

However once you fill it, how often do you plan to change the diff fluid? Every 50k? If so what about one of these and be done with it. 50K might take 10 years or more to put on one of these cars unless its your daily driver. Unless the coolness factor of the finned cover is what your after.

moparmat2000

Well-Known Member

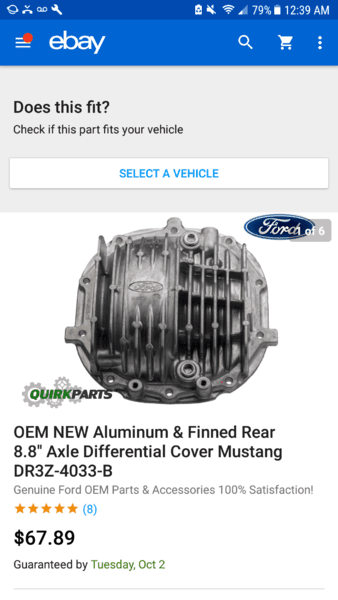

Same finned cover from ford motorsports but with threaded plugs. I have pipe taps, so i would buy the cheaper cover, drill and tap it.

moparmat2000

Well-Known Member

However i may just go with a chromed steel cover for that 70s look, or just repaint the stocker i already have black after welding on fill and drain ports to it. I mean how hot is that diff fluid really going to get rolling down the highway at 70-75 mph

loganscuda

This/These

That cover $20 at pick n pull

moparmat2000

Well-Known Member

I will probably just paint and reinstall the stocker, but thats a good deal. I may just grab one myself next time I hit the Pick and Pull.

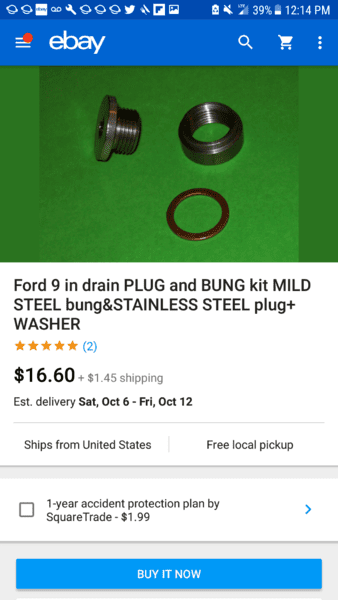

Heres the weld in drain for the steel cover.

Heres the weld in drain for the steel cover.

Last edited:

moparmat2000

Well-Known Member

Well i was going to start pulling this thing apart to make my tube cuts, but 1/4" of solid crust blocked my way. Even if i intend to rebuild it, i'm not a big fan of dirt and crap falling inside, plus i hate working on dirty ****. If the bearings look good i will just reassemble it for now as its only going under my sons car as a roller/sitter for a couple years. Will get rebuilt when we start on his car project.

I put paper and a drain pan down. I scraped most of it off, then got out the heavy duty easy off oven cleaner and soaked the area. Let it sit about 30 minutes, then began scrubbing with an old 1" paint brush. Rinse off with a squirt bottle of water, scrub and reapply. I have limited time these days so i only had about an hour and a half to work on it. All I got done was get it cleaned up.

Today after work i will flip it upside down, go medieval on it with the heavy duty wire wheel, and primer the bottom. Then remove the cover and let it drain out. As an added pic, i stuck my blanked off VSS sensor back in to see how it all looks with the ears cut off. I think it looks great.

I intend to put the 3L73 tag and the diff oil information tags back on when i put the cover back on. Just going to trim them down to remove the excess numbers on them.

I put paper and a drain pan down. I scraped most of it off, then got out the heavy duty easy off oven cleaner and soaked the area. Let it sit about 30 minutes, then began scrubbing with an old 1" paint brush. Rinse off with a squirt bottle of water, scrub and reapply. I have limited time these days so i only had about an hour and a half to work on it. All I got done was get it cleaned up.

Today after work i will flip it upside down, go medieval on it with the heavy duty wire wheel, and primer the bottom. Then remove the cover and let it drain out. As an added pic, i stuck my blanked off VSS sensor back in to see how it all looks with the ears cut off. I think it looks great.

I intend to put the 3L73 tag and the diff oil information tags back on when i put the cover back on. Just going to trim them down to remove the excess numbers on them.

moparmat2000

Well-Known Member

Being that it already has an existing fill port, why not drill and tap with an 1/8" pipe tap for an 1/8" allen key flush pipe plug far enough forward in the casting, and off to the side so its not lined up with any of the bolt holes or close to the back to lessen any stress. I marked in the pic where i think it would be a good idea for a drain plug. Its far enough forward that it wont weaken the casting. Its between 2 bolts and not lined up directly forward of one. 1/8" pipe plug is a small hole, so it shouldent weaken the case much if any. I wouldent recommend this for high HP applications but 400-450 application i would think it would be fine. What do any of you think about this?

I did that exact thing thing to a 9" a long time ago. I got tired of cracking the chunk everytime I wanting to change the diff oil. Which was often because I was submerging my 4x4 a lot.Being that it already has an existing fill port, why not drill and tap with an 1/8" pipe tap for an 1/8" allen key flush pipe plug far enough forward in the casting, and off to the side so its not lined up with any of the bolt holes or close to the back to lessen any stress. I marked in the pic where i think it would be a good idea for a drain plug. Its far enough forward that it wont weaken the casting. Its between 2 bolts and not lined up directly forward of one. 1/8" pipe plug is a small hole, so it shouldent weaken the case much if any. I wouldent recommend this for high HP applications but 400-450 application i would think it would be fine. What do any of you think about this?

View attachment 1715228886

View attachment 1715228887

moparmat2000

Well-Known Member

Did you drill the chunk or the steel axle housing on that 9" ?

Last edited:

moparmat2000

Well-Known Member

Finished the cleaning up with a wire wheel, primered and cracked open the cover. The diff oil was very clean, and the gear teeth look great. Cover was glued on with silicone. I never eyeballed the miles on the exploder i took it off of. I should have though.

Bottom of the housing.Did you drill the chunk or the steel axle housing on that 9" ?[/

moparmat2000

Well-Known Member

Being that this housing is cast, i am having second thoughts.

I wouldn’t do it just buy an aluminum cover with the drain plug and be done with it. This one has fill, drain, and girdle it’s a triple threat.Being that this housing is cast, i am having second thoughts.

moparmat2000

Well-Known Member

Wow, either i got an axle from a coastal or rust belt truck. Are they ALL like this in this area?? I wire wheeled the living **** outta this area on the axle. I still have to grind everything down to smooth unpitted steel. I will be using an epoxy etch primer in this location to keep the corrosion at bay. Anybody else pull one apart and find bad corrosion in this area?

Last edited:

Dartfreak75

Restore it, Dont part it!

I personally prefer this one simply for the fact it doesn't say Ford on it. And it's more speak appearing just my personal opinion.However once you fill it, how often do you plan to change the diff fluid? Every 50k? If so what about one of these and be done with it. 50K might take 10 years or more to put on one of these cars unless its your daily driver. Unless the coolness factor of the finned cover is what your after.

View attachment 1715228521

moparmat2000

Well-Known Member

36 grit, then 80 grit, ground off all the pits. Looked clean after the wire wheel, but when i hit it, brown dust started to fly lol.

moparmat2000

Well-Known Member

I was headed that way actually.I personally prefer this one simply for the fact it doesn't say Ford on it. And it's more speak appearing just my personal opinion.

moparmat2000

Well-Known Member

A final grinding to remove remaining peppering pits. A sanding with 80 grit on a DA sander. I will hit it with some epoxy etch primer tomorrow afternoon. Heres some recap photos. Crap, now i have to do the other side.

moparmat2000

Well-Known Member

For now i will use the stock cover. I need to sand blast , prime, and paint it up.

Anybody need a long side axle?

Anybody need a long side axle?

moparmat2000

Well-Known Member

Long side is 20" from backside of flange to chunk. Short end it 17&1/8" from back side of flange to chunk. So some simple math puts the long side to be shortened by 2&7/8". I sprayed the tube with machinest dye. I used my 3" C channel to get a lay line. Then i measured 10 inches, dead center on the long tube. Measured 1&1/2 on one side of the center line, 1&3/8" on the other side of the center line. This gets the weld close to center on the tube. Probably the strongest point on the tube for it to be. Depending on where i get with it tomorrow, i may be cutting and chamfering the tubes. I may make something out of the piece i cut out of the tube. I'm tired, I'm going to get some rest.

Last edited:

moparmat2000

Well-Known Member

Didnt get to the cut today, but i finished up fixing the rusty ends permanently. Fluid resistant etch epoxy. Permanent fix.

moparmat2000

Well-Known Member

Well initial cut is done 1/16" oversizex so i can work the metal down to get the butt tighter all the way around. Now i just have to take my time filing it down. But I need two cheap 5" C clamps. Time to hit up "china freight" harbor freight after work tomorrow . I have a single 4 and a single 6. Not gonna cut it. Cant go wrong with more C clamps though.

Got that ring of steel cut out of the tube. Thinking of making a sodapop can holder for my toolbox at work out of it, or weld a bottom on it and make it a pen holder/paperweight.

Got that ring of steel cut out of the tube. Thinking of making a sodapop can holder for my toolbox at work out of it, or weld a bottom on it and make it a pen holder/paperweight.

moparmat2000

Well-Known Member

So the insides of these axle tubes have a semidry sticky black gunk in them. I am assuming old clutch friction material mixed with old gear oil. I need to pull the ring and pinion out and clean out the gear oil and this black sticky **** out of at least on one side before i finally weld this thing up. How have you guys douched out these axle tubes on your 8.8 i was thinking laquer thinner and a 1" or 2" paintbrush attached to a long stick and that would prob work fine on the left side with the end cut off, but the passenger side notsomuch.

Last edited:

-