AlV

Crabs in a barrel

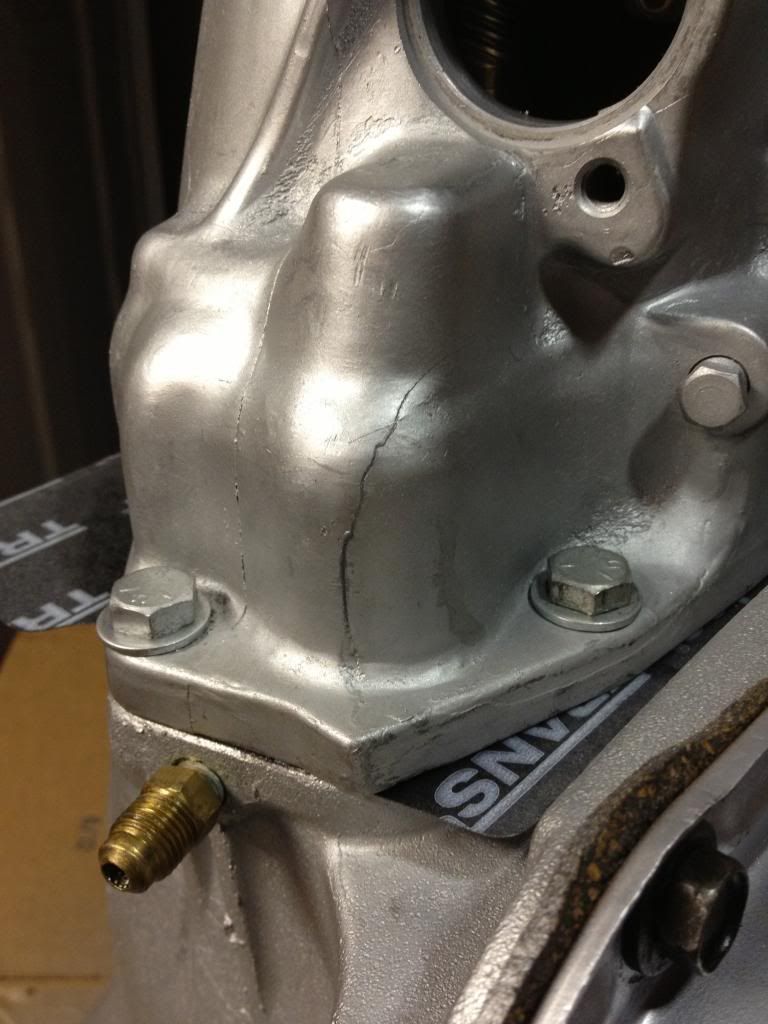

As I was finishing up I did a bit of final clean and paint when I noticed something that I hadn't seen before.

Thought it was odd so put stone tip on my dremel and figured it wouldn't hurt to see what I see.

It appears to be a surface issue... not sure what it was. I looked on the inside it it was clear. I decided to roll with it... cleaned it up and put some paint on it

On to the next thing.

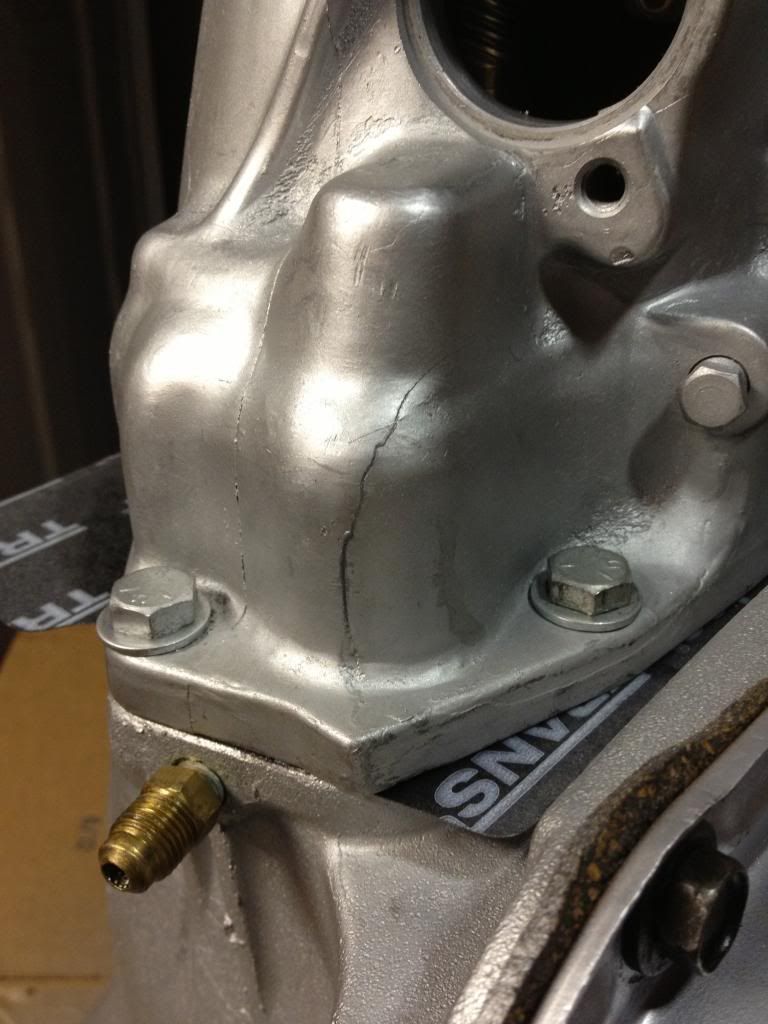

Thought it was odd so put stone tip on my dremel and figured it wouldn't hurt to see what I see.

It appears to be a surface issue... not sure what it was. I looked on the inside it it was clear. I decided to roll with it... cleaned it up and put some paint on it

On to the next thing.