Here are two assembly tricks for a 4-speed transmission I came up with (haven't seen these before):

The most cumbersome job (at least for me) when assembling an A833 is to mate the main shaft assembly with the main case. The loaded main shaft (I know I know ;) ) is quite heavy and since you have to do several things at the same time when lowering the shaft (guide it into the input shaft, move the synchro sleeves around the gears, align the speed gears with the counter shaft teeth), while paying attention not to drop the 3-4 synchro sleeve and let the synchro keys fly off the synchro hub, this task can cause a lot of frustration.

So in order to make things a little easier (especially when you don't have a helper or only one that is useless) I used electrical tape to hold the keys in the synchro hub and prevent the sleeve from dropping. Once the snychro sleeve is a little past 3rd gear on the cluster gear (that is the reason why you have to move the sleeve forward - otherwise you can't guide the main shaft into the input shaft) you can remove the tape. Push the synchro towards the rear when removing the tape - once it is off the sleeve should slide all the way back.

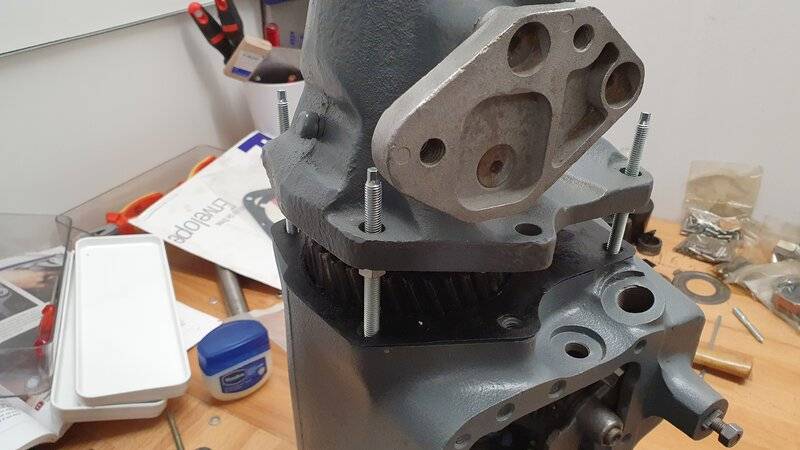

And one more thing: use studs/bolts and nuts to hold up the tail housing and main shaft. You can now slowly lower the shaft by turning the nuts (or hold the nuts and turn the studs/bolts if you use smaller ones than the thread in the main case - actually easier as you have better access to the bolt heads than the nuts - I used M8 studs) which makes it way easier to align everything and have things under control. When you are almost all the way down (1/2" to go) insert some sort of spacer (wooden board etc.) into the gap. Lower the tail housing some more until it firmly rests on the spacers. Now remove the studs and nuts and then take out the spacers - the tail housing should now slide in the remaining distance.

btw. if your shifter mounting plate is already attached to the tail housing (I left mine on as I couldn't get the bolts out) already drop the bolt (that holds the tail housing to the main housing) in the bolt hole. Otherwise it can be a challenge to get it in (I did manage to do it but took some time).

The most cumbersome job (at least for me) when assembling an A833 is to mate the main shaft assembly with the main case. The loaded main shaft (I know I know ;) ) is quite heavy and since you have to do several things at the same time when lowering the shaft (guide it into the input shaft, move the synchro sleeves around the gears, align the speed gears with the counter shaft teeth), while paying attention not to drop the 3-4 synchro sleeve and let the synchro keys fly off the synchro hub, this task can cause a lot of frustration.

So in order to make things a little easier (especially when you don't have a helper or only one that is useless) I used electrical tape to hold the keys in the synchro hub and prevent the sleeve from dropping. Once the snychro sleeve is a little past 3rd gear on the cluster gear (that is the reason why you have to move the sleeve forward - otherwise you can't guide the main shaft into the input shaft) you can remove the tape. Push the synchro towards the rear when removing the tape - once it is off the sleeve should slide all the way back.

And one more thing: use studs/bolts and nuts to hold up the tail housing and main shaft. You can now slowly lower the shaft by turning the nuts (or hold the nuts and turn the studs/bolts if you use smaller ones than the thread in the main case - actually easier as you have better access to the bolt heads than the nuts - I used M8 studs) which makes it way easier to align everything and have things under control. When you are almost all the way down (1/2" to go) insert some sort of spacer (wooden board etc.) into the gap. Lower the tail housing some more until it firmly rests on the spacers. Now remove the studs and nuts and then take out the spacers - the tail housing should now slide in the remaining distance.

btw. if your shifter mounting plate is already attached to the tail housing (I left mine on as I couldn't get the bolts out) already drop the bolt (that holds the tail housing to the main housing) in the bolt hole. Otherwise it can be a challenge to get it in (I did manage to do it but took some time).

Last edited: